- Joined

- Jun 27, 2024

- Messages

- 1,006

- Likes

- 3,124

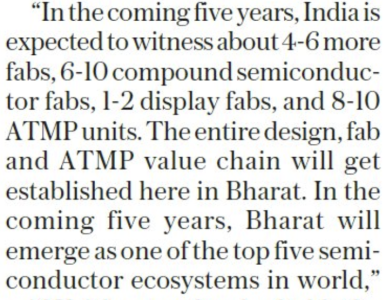

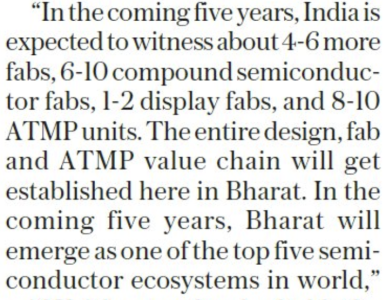

Will discuss all about the Indian Semi Conductor developments on this thread.

theprint.in

theprint.in

Sachin Tendulkar Backed RRP Electronics Ltd Unveils Semiconductor Milestone With Inauguration Of Cutting-Edge Facility In Maharashtra

PNN Mumbai (Maharashtra) [India], March 23: RRP Electronics Ltd, in a historic collaboration with a prestigious European consortium, proudly announced the inauguration of Maharashtra’s pioneering semiconductor facility. This groundbreaking endeavour signifies a monumental leap forward...

theprint.in

theprint.in

Last edited: