You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Russian Aerospace Industry

- Thread starter haldilal

- Start date

More options

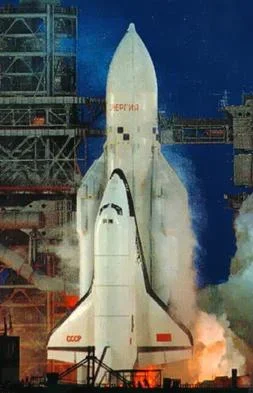

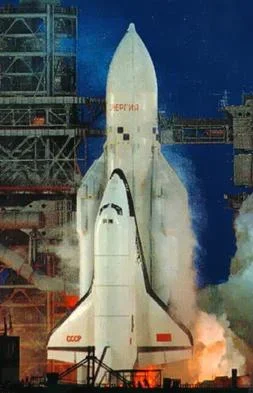

Who Replied?Spacecraft Buran to be restored in Russia

View: https://youtu.be/IyOUdCfag8g?si=6wDpnbVfTt2XSZt5

en.wikipedia.org

en.wikipedia.org

View: https://youtu.be/IyOUdCfag8g?si=6wDpnbVfTt2XSZt5

Buran (spacecraft) - Wikipedia

The Soviet space shuttle Buran was the first of its kind unmanned space drone in the 1980s something that the NASA was lacking.

View: https://youtu.be/Q6WHjQ3Y3Uo?si=vrvnYRbnz0drH8Vu

View: https://youtu.be/Q6WHjQ3Y3Uo?si=vrvnYRbnz0drH8Vu

<iframe width="640" height="360" src="

View: https://www.youtube.com/embed/ZABqdBwWyTc" title="ГРОМ, С-76, ЛАНЦЕТ, МОТЫЛЁК и другие БПЛА "Армии-2024"" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>

View: https://www.youtube.com/embed/ZABqdBwWyTc" title="ГРОМ, С-76, ЛАНЦЕТ, МОТЫЛЁК и другие БПЛА "Армии-2024"" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>

<iframe width="640" height="360" src="

View: https://www.youtube.com/embed/c9xZvyCMZXU" title="RUN before it's TOO LATE: The Newest Su-57M With 5th-GEN Engine 'AL-51F1' Enters The BATTLEFIELD" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>

View: https://www.youtube.com/embed/c9xZvyCMZXU" title="RUN before it's TOO LATE: The Newest Su-57M With 5th-GEN Engine 'AL-51F1' Enters The BATTLEFIELD" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>

- Joined

- Jul 1, 2024

- Messages

- 307

- Likes

- 2,189

- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

he first flight of the SJ-100 aircraft with domestic PD-8 engines

March 17th, 23:08

As reported by PJSC United Aircraft Corporation (UAC), on March 17, 2025, the first flight of the prototype of the modified regional passenger aircraft SJ-100 (SSJ100) Superjet️ with two new Russian PD-8 engines took place in Komsomolsk-on-Amur. The PD-8 engines were installed instead of the standard SaM146 on the Superjet️ aircraft with factory number 95157 (OP-2, serial number 157) and registration number 97012, built in 2018. This marked the beginning of flight tests of the PD-8 as part of the SJ-100 Superjet️ under the SSJ-NEW program.

The first flight of the prototype of the modified regional passenger aircraft SJ-100 (SSJ100) Superjet️ (OP-2, factory number 95157, serial number 157, registration number 97012) with two new Russian engines PD-8. Komsomolsk-on-Amur, 17.03.2025 (c) PJSC United Aircraft Corporation

The flight was performed by a crew consisting of test pilots Dmitry Aleksandrovich Demenev, Igor Yuryevich Grevtsev and flight operator Maxim Grigorievich Grukanov. The aircraft was in the air for about 40 minutes, reached a speed of 500 km/h and an altitude of up to 3000 m.

After landing, the crew commander reported that the flight mission had been completed in full. The power plant with PD-8 engines demonstrated stable operation; the gas-dynamic stability of the engines was assessed in flight in constant and variable modes.

“The aircraft with the PD-8 power plant has joined the flight tests - this is an important and long-awaited step towards certification of the technologically independent version of the Superjet. Complete dedication and overcoming of all challenges by the engine builders allowed the aircraft to successfully complete its first flight on Russian engines. To intensify the certification tests, the manufacturer plans to connect a third, fully Russian Superjet to them. We expect that this work will be carried out on schedule, the state provides the necessary financial and resource support to aircraft manufacturers in full," said Denis Manturov, First Deputy Prime Minister of the Russian Federation and Chairman of the Supervisory Board of Rostec State Corporation.

As part of Rostec State Corporation, work on the Superjet import substitution program is carried out by a large cooperation of enterprises under the auspices of the Yakovlev company of the United Aircraft Corporation. The new Russian power plants were created by specialists of the United Engine Corporation.

"Today's flight confirms the correctness of our engineering calculations and the high readiness of the aircraft. The project is being implemented in a very tight time frame by the standards of the global aircraft industry. After 2022, the Superjet will have to be essentially reassembled from scratch. At the same time, the engine is one of the key elements of the import substitution program, it is the "heart" of the aircraft. There is still a lot of work and many flights ahead. In April, another fully Russian aircraft with PD-8 engines will join the certification flight tests,” said Sergey Chemezov, CEO of Rostec State Corporation.

For the first flight on domestic engines, a prototype of the Superjet with serial number 95157, manufactured in 2018, was used.

“The first flight of the Superjet on the PD-8, on the one hand, sums up the large and complex work done jointly with colleagues from UEC, and on the other hand, opens a new important stage in testing the engine as part of the aircraft. Flight tests of the PD-8 engines on the Superjet begin on an aircraft in serial form with imported systems, since the level of “novelty” in testing such important components as the engine must be increased gradually. This approach will allow us to ensure the necessary certification rates, as well as to work out technical solutions for the possibility of subsequent re-motorization of the currently flying Superjets fleet, - said Vadim Badekha, CEO of UAC.

He also noted that joining the flights of the aircraft in a completely Russian version will allow us to study the interaction of the power plant with PD-8 engines with domestic systems during certification flight tests.

"The flight of the aircraft with new domestic PD-8 engines has become one of the most anticipated events of this year. The engine showed good results and fully confirmed all its technical characteristics. I am grateful to the entire large team of UEC and UAC, as well as the management of the Ministry of Industry and Trade, Rosaviatsia, Rostec State Corporation and the NRC "Institute named after N.E. Zhukovsky" for this common result. By the end of March, we plan to transfer two more experimental PD-8 engines for flight tests. “The receipt of the type certificate for the PD-8 engine is planned for the fall of this year,” noted the General Director of UEC, member of the Board of the All-Russian industry association of employers “Union of Machine Builders of Russia” Alexander Grachev.

“Our common goal is to provide operators with a safe

and a high-quality Russian aircraft for comfortable passenger transportation on regional and short-haul routes. The Superjet in its new appearance is extremely necessary for solving the strategic tasks that the country's leadership has set for all air transport. This is an increase in the air mobility of our citizens and an increase in the intensity of air traffic in Russia by 1.5 times by 2030," said Dmitry Yadrov, head of the Federal Air Transport Agency.

The PD-8 bypass turbofan engine with a thrust of 8 tons for the Superjet passenger aircraft and the Be-200 amphibious aircraft was created using new Russian materials and advanced technologies. The work involves broad cooperation between UEC enterprises, and the experience of creating the PD-14 engine is actively used.

As part of the import substitution work on the short-haul narrow-body airliner "Superjet", about 40 imported systems and units are being replaced, including the engine, avionics, chassis, auxiliary power unit, integrated control system, power supply systems, air conditioning, fire protection and others. The aircraft also received a domestic fuselage, which was modified to simplify the production and maintenance of the aircraft.

The first flight of the prototype of the modified regional passenger aircraft SJ-100 (SSJ100) Superjet️ (OP-2, factory number 95157, serial number 157, registration number 97012) with two new Russian engines PD-8. Komsomolsk-on-Amur, 03/17/2025 (c) PJSC United Aircraft Corporation

March 17th, 23:08

As reported by PJSC United Aircraft Corporation (UAC), on March 17, 2025, the first flight of the prototype of the modified regional passenger aircraft SJ-100 (SSJ100) Superjet️ with two new Russian PD-8 engines took place in Komsomolsk-on-Amur. The PD-8 engines were installed instead of the standard SaM146 on the Superjet️ aircraft with factory number 95157 (OP-2, serial number 157) and registration number 97012, built in 2018. This marked the beginning of flight tests of the PD-8 as part of the SJ-100 Superjet️ under the SSJ-NEW program.

The first flight of the prototype of the modified regional passenger aircraft SJ-100 (SSJ100) Superjet️ (OP-2, factory number 95157, serial number 157, registration number 97012) with two new Russian engines PD-8. Komsomolsk-on-Amur, 17.03.2025 (c) PJSC United Aircraft Corporation

The flight was performed by a crew consisting of test pilots Dmitry Aleksandrovich Demenev, Igor Yuryevich Grevtsev and flight operator Maxim Grigorievich Grukanov. The aircraft was in the air for about 40 minutes, reached a speed of 500 km/h and an altitude of up to 3000 m.

After landing, the crew commander reported that the flight mission had been completed in full. The power plant with PD-8 engines demonstrated stable operation; the gas-dynamic stability of the engines was assessed in flight in constant and variable modes.

“The aircraft with the PD-8 power plant has joined the flight tests - this is an important and long-awaited step towards certification of the technologically independent version of the Superjet. Complete dedication and overcoming of all challenges by the engine builders allowed the aircraft to successfully complete its first flight on Russian engines. To intensify the certification tests, the manufacturer plans to connect a third, fully Russian Superjet to them. We expect that this work will be carried out on schedule, the state provides the necessary financial and resource support to aircraft manufacturers in full," said Denis Manturov, First Deputy Prime Minister of the Russian Federation and Chairman of the Supervisory Board of Rostec State Corporation.

As part of Rostec State Corporation, work on the Superjet import substitution program is carried out by a large cooperation of enterprises under the auspices of the Yakovlev company of the United Aircraft Corporation. The new Russian power plants were created by specialists of the United Engine Corporation.

"Today's flight confirms the correctness of our engineering calculations and the high readiness of the aircraft. The project is being implemented in a very tight time frame by the standards of the global aircraft industry. After 2022, the Superjet will have to be essentially reassembled from scratch. At the same time, the engine is one of the key elements of the import substitution program, it is the "heart" of the aircraft. There is still a lot of work and many flights ahead. In April, another fully Russian aircraft with PD-8 engines will join the certification flight tests,” said Sergey Chemezov, CEO of Rostec State Corporation.

For the first flight on domestic engines, a prototype of the Superjet with serial number 95157, manufactured in 2018, was used.

“The first flight of the Superjet on the PD-8, on the one hand, sums up the large and complex work done jointly with colleagues from UEC, and on the other hand, opens a new important stage in testing the engine as part of the aircraft. Flight tests of the PD-8 engines on the Superjet begin on an aircraft in serial form with imported systems, since the level of “novelty” in testing such important components as the engine must be increased gradually. This approach will allow us to ensure the necessary certification rates, as well as to work out technical solutions for the possibility of subsequent re-motorization of the currently flying Superjets fleet, - said Vadim Badekha, CEO of UAC.

He also noted that joining the flights of the aircraft in a completely Russian version will allow us to study the interaction of the power plant with PD-8 engines with domestic systems during certification flight tests.

"The flight of the aircraft with new domestic PD-8 engines has become one of the most anticipated events of this year. The engine showed good results and fully confirmed all its technical characteristics. I am grateful to the entire large team of UEC and UAC, as well as the management of the Ministry of Industry and Trade, Rosaviatsia, Rostec State Corporation and the NRC "Institute named after N.E. Zhukovsky" for this common result. By the end of March, we plan to transfer two more experimental PD-8 engines for flight tests. “The receipt of the type certificate for the PD-8 engine is planned for the fall of this year,” noted the General Director of UEC, member of the Board of the All-Russian industry association of employers “Union of Machine Builders of Russia” Alexander Grachev.

“Our common goal is to provide operators with a safe

and a high-quality Russian aircraft for comfortable passenger transportation on regional and short-haul routes. The Superjet in its new appearance is extremely necessary for solving the strategic tasks that the country's leadership has set for all air transport. This is an increase in the air mobility of our citizens and an increase in the intensity of air traffic in Russia by 1.5 times by 2030," said Dmitry Yadrov, head of the Federal Air Transport Agency.

The PD-8 bypass turbofan engine with a thrust of 8 tons for the Superjet passenger aircraft and the Be-200 amphibious aircraft was created using new Russian materials and advanced technologies. The work involves broad cooperation between UEC enterprises, and the experience of creating the PD-14 engine is actively used.

As part of the import substitution work on the short-haul narrow-body airliner "Superjet", about 40 imported systems and units are being replaced, including the engine, avionics, chassis, auxiliary power unit, integrated control system, power supply systems, air conditioning, fire protection and others. The aircraft also received a domestic fuselage, which was modified to simplify the production and maintenance of the aircraft.

The first flight of the prototype of the modified regional passenger aircraft SJ-100 (SSJ100) Superjet️ (OP-2, factory number 95157, serial number 157, registration number 97012) with two new Russian engines PD-8. Komsomolsk-on-Amur, 03/17/2025 (c) PJSC United Aircraft Corporation

- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

In this exclusive interview, Kirill Kuznetsov, the chief designer of the SJ-100 Superjet, takes us behind the scenes of the aircraft's rigorous certification process. As Russia's newest regional jet, the SJ-100 represents a significant leap in aviation technology, and Kuznetsov provides an in-depth look at the challenges and breakthroughs encountered during its system testing.

View: https://www.youtube.com/watch?v=8K2vP4LxF6k

View: https://www.youtube.com/watch?v=8K2vP4LxF6k

- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

Alexander Dolotovsky, Deputy General Director of PJSC "Yakovlev" and Director of the Superjet Program, shares details about the certification tests taking place in Komsomolsk and Zhukovsky, as well as the reasons why the Superjet needs winglets and a Russian-made cabin

View: https://www.youtube.com/watch?v=TwMZC3aPE6U

View: https://www.youtube.com/watch?v=TwMZC3aPE6U

- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

New Tu-214 aircraft built

March 1st, 23:00

On December 27, 2024, another Tu-214 aircraft built at this enterprise made its maiden flight at the airfield of the Kazan Aviation Plant named after S.P. Gorbunov, a branch of PJSC Tupolev (part of PJSC United Aircraft Corporation of the Rostec State Corporation). The aircraft with the factory number (short) 035, serial number 535 and registration number RA-64535 was built as a VIP cabin for the Ministry of Industry and Trade of the Russian Federation and became the first new Tu-214 aircraft to take to the air in three and a half years.

The new Tu-214 aircraft (factory number 035, serial number 535, registration number RA-64535), built by the Kazan Aviation Plant named after S.P. Gorbunov, made its maiden flight on December 27, 2024. Gorbunov - a branch of PJSC Tupolev (part of PJSC United Aircraft Corporation of the Rostec State Corporation). Minsk, 02/24/2025 (c) Denisin / russianplanes.net ( link )

It is reported that on February 24, 2025, the RA-64535 aircraft flew from Kazan to Minsk for painting.

The previous Tu-214 aircraft built at the Kazan Aviation Plant was the Tu-214PU (factory number 44912034, serial number 534, registration number RA-64534), which took off on May 28, 2021, and was presumably built for the Federal Security Service (FSB) of the Russian Federation.

In total, 35 Tu-214 aircraft have been built at the Kazan Aviation Plant to date, and the total number of Tu-204/Tu-214 family aircraft built in the USSR and Russia since 1989, including prototypes, has reached 91 units.

The new Tu-214 aircraft (factory number 035, serial number 535, registration number RA-64535), built by the Kazan Aviation Plant named after S.P. Gorbunov, a branch of PJSC Tupolev (part of PJSC United Aircraft Corporation of the Rostec State Corporation). Kazan, 02/24/2025 (c) Timur Badredtinov / russianplanes.net ( link )

March 1st, 23:00

On December 27, 2024, another Tu-214 aircraft built at this enterprise made its maiden flight at the airfield of the Kazan Aviation Plant named after S.P. Gorbunov, a branch of PJSC Tupolev (part of PJSC United Aircraft Corporation of the Rostec State Corporation). The aircraft with the factory number (short) 035, serial number 535 and registration number RA-64535 was built as a VIP cabin for the Ministry of Industry and Trade of the Russian Federation and became the first new Tu-214 aircraft to take to the air in three and a half years.

The new Tu-214 aircraft (factory number 035, serial number 535, registration number RA-64535), built by the Kazan Aviation Plant named after S.P. Gorbunov, made its maiden flight on December 27, 2024. Gorbunov - a branch of PJSC Tupolev (part of PJSC United Aircraft Corporation of the Rostec State Corporation). Minsk, 02/24/2025 (c) Denisin / russianplanes.net ( link )

It is reported that on February 24, 2025, the RA-64535 aircraft flew from Kazan to Minsk for painting.

The previous Tu-214 aircraft built at the Kazan Aviation Plant was the Tu-214PU (factory number 44912034, serial number 534, registration number RA-64534), which took off on May 28, 2021, and was presumably built for the Federal Security Service (FSB) of the Russian Federation.

In total, 35 Tu-214 aircraft have been built at the Kazan Aviation Plant to date, and the total number of Tu-204/Tu-214 family aircraft built in the USSR and Russia since 1989, including prototypes, has reached 91 units.

The new Tu-214 aircraft (factory number 035, serial number 535, registration number RA-64535), built by the Kazan Aviation Plant named after S.P. Gorbunov, a branch of PJSC Tupolev (part of PJSC United Aircraft Corporation of the Rostec State Corporation). Kazan, 02/24/2025 (c) Timur Badredtinov / russianplanes.net ( link )

bmpd

bmpd - the new blog in LiveJournal. There should be new interesting records soon.- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

In a landmark achievement for Russia's aviation industry, a prototype of the Superjet aircraft equipped with domestically developed PD-8 engines successfully completed its maiden flight in Komsomolsk-on-Amur. This event signifies the commencement of flight tests for the PD-8 engine as part of the Superjet program, a critical step toward certifying a fully import-substituted version of the aircraft. The flight, which lasted approximately 40 minutes, reached an altitude of 3,000 meters and a speed of 500 km/h, with the crew reporting stable engine performance and successful completion of the mission.The PD-8 engine, designed to replace the Franco-Russian SaM146 engines, is a key component of Russia's efforts to develop a technologically independent Superjet in response to international sanctions. The prototype aircraft used for the flight, manufactured in 2018, represents a transitional phase, as it still incorporates some imported systems. However, the ultimate goal is to integrate the PD-8 into the fully Russian SJ-100, which will feature over 40 domestically produced systems, including avionics, landing gear, and fire protection systems.Russian officials, including Denis Manturov, First Deputy Prime Minister, and Rostec CEO Sergey Chemezov, emphasized the importance of this milestone, highlighting the extensive collaboration between Rostec, the United Aircraft Corporation (UAC), and the United Engine Corporation (UEC). The project, which has been accelerated under tight deadlines, aims to achieve certification for the PD-8 engine by fall 2024.The successful flight not only validates the technical capabilities of the PD-8 engine but also sets the stage for further testing and certification. With plans to introduce additional prototype engines and a fully Russian-configured aircraft into the testing program, Russia is steadily advancing toward its goal of creating a self-reliant aviation industry. This achievement underscores the nation's resilience and determination to overcome technological challenges posed by global sanctions.

View: https://www.youtube.com/watch?v=XeNjxEmIll0

View: https://www.youtube.com/watch?v=XeNjxEmIll0

- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

The production of the Tupolev Tu-204 and Tu-214 aircraft was strategically divided between two plants: Kazan Aviation Plant (KAPO) and Aviastar-SP in Ulyanovsk. This decision, influenced by economic and operational concerns, was made during a tumultuous period in the Russian aviation industry following the collapse of the Soviet Union. Aviastar-SP began Tu-204 production in 1992, while KAPO introduced the Tu-214 derivative in 1996.The Role of KAPO and Aviastar-SPThe Tu-214, a modified version of the Tu-204, was designed for extended range and increased payload capacity, requiring specialized manufacturing procedures. KAPO, with a background in military aircraft production, leveraged its expertise and infrastructure to transition into civilian aircraft manufacturing. This shift allowed KAPO to retain its skilled workforce while adapting to new production demands.Meanwhile, Aviastar-SP continued manufacturing Tu-204 variants, ensuring the availability of multiple models to meet market needs. The division of labor between the two plants allowed for better personnel utilization, resource allocation, and reduced lead times for aircraft deliveries.Government Influence and Economic StabilityThe Russian government played a crucial role in supporting this dual-plant manufacturing model. A key factor in this decision was job preservation in multiple regions, ensuring economic stability during an uncertain period. By subsidizing both plants, the government sought to revitalize domestic aircraft manufacturing and sustain technological capabilities in Russia’s aviation sector.Modernization and Production ShiftsAs part of Russia’s broader strategy to expand its aviation industry, both KAPO and Aviastar-SP have embarked on modernization efforts. KAPO is enhancing its production capacity to align with the government's ambitious targets for Tu-214 production, aiming for a substantial increase in annual output.However, Aviastar-SP’s focus is shifting. The last recorded Tu-204 aircraft, a Tu-204-300 VIP version, was delivered to the Russian government in 2016. Since then, there have been no confirmed reports of new Tu-204 production, suggesting that Aviastar-SP is redirecting its efforts toward maintenance and modernization of existing Tu-204 fleets rather than manufacturing new units.Is Aviastar-SP Abandoning Civilian Aircraft?Rather than completely withdrawing from civilian aviation, Aviastar-SP is undergoing a strategic realignment. The company is heavily involved in military aircraft programs, including:Antonov An-124 Ruslan Modernization—Aviastar-SP is upgrading three An-124 aircraft under a government contract to enhance reliability and extend service life.Il-76MD-90A Heavy Transport Aircraft—Aviastar-SP is engaged in major design upgrades, including new engines, reinforced landing gear, and modernized navigation systems.Il-114-300 and MC-21 Participation—The plant contributes to the production of regional and medium-haul aircraft components, supporting Russia’s aviation sector.Potential Tu-204 Tanker Variant—There have been discussions about a military refueling version of the Tu-204, though the project remains in the conceptual phase.The Future of Aviastar-SP: A Military-Oriented FocusAviastar-SP's primary focus has shifted towards military aviation, particularly with the Il-76MD-90A transport aircraft. Under a contract with the Russian Ministry of Defense, the plant is expected to produce 39 Il-76MD-90A units, solidifying its role in military aircraft production.This transformation reflects a broader trend in Russia’s aviation industry, where geopolitical and economic factors have driven an increased emphasis on military manufacturing. Although Aviastar-SP may still contribute to civilian aircraft production, its long-term trajectory appears increasingly aligned with defense aviation initiatives.

View: https://www.youtube.com/watch?v=Jc4qY_PugBg

View: https://www.youtube.com/watch?v=Jc4qY_PugBg

- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

Russia's aircraft manufacturing industry is undergoing major revisions due to production constraints, geopolitical challenges, and supply chain disruptions. Deputy Prime Minister Denis Manturov has indicated that the civilian aircraft production program will be adjusted by the end of 2025, while Rostec CEO Sergey Chemezov estimates that only 200 aircraft are necessary by 2030, significantly lower than the government's initial goal of 994 aircraft.Basic calculations reveal that achieving Chemezov’s target requires building one aircraft every 8.75 days, a rate far beyond Russia’s historical output. Sanctions following Russia's 2022 invasion of Ukraine have halted the serial production of passenger aircraft, exacerbating delays. Key projects, including the SSJ-NEW and MC-21, rely on domestic replacements for Western-made engines and components. The SSJ-NEW is transitioning from French SaM146 engines to Russia's PD-8, while the MC-21 is shifting from American Pratt & Whitney engines to the Russian PD-14. Certification for these aircraft is still pending, further pushing back their production timelines.While mid-range aircraft like the Tu-214 and long-haul Il-96-400 remain in development, their Soviet-era designs and reliance on outdated systems create additional hurdles. Meanwhile, Russia's aviation sector is struggling to replace aging regional aircraft, such as the An-24 and An-26, which are still widely used but face mandatory service life extensions. New regional aircraft projects, including the Il-114-300, LMS-192 "Osvey," TVRS-44 "Ladoga," and LMS-901 "Baikal," are all delayed, with some not expected to enter production until 2027 or later.With Western-made Airbus and Boeing jets still forming the backbone of Russia's airline fleets, the industry's ability to meet domestic aviation needs remains uncertain. Stopgap solutions, such as retrofitting old Soviet aircraft like the An-2, indicate the depth of the crisis. Unless manufacturing speeds up significantly, Russia risks long-term setbacks in its civilian aviation sector.

View: https://www.youtube.com/watch?v=5hTJcFYXKWU

View: https://www.youtube.com/watch?v=5hTJcFYXKWU

- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

View: https://www.youtube.com/watch?v=KuNuIe2f0sw

The MC-21, a promising Russian passenger aircraft, faces a lengthy certification and refinement process, delaying its entry into commercial service until at least 2028. Test pilot Roman Taskaev highlighted the challenges, noting that while the aircraft's design and characteristics are appealing to Russian airlines, its full potential remains unrealized. Certification, a rigorous process involving both the aircraft and its components, is ongoing, with localized PD-14 engines set for certification flights in 2025.The Irkutsk Aviation Plant is undergoing a significant modernization to support mass production of the MC-21, targeting 36 aircraft per year by 2026. This upgrade includes facility construction, warehouse expansion, and technical enhancements to ensure high-quality production and maintenance. Additionally, South-Russian State Polytechnical University has developed a cutting-edge composite wing production system, replacing imported technology and strengthening domestic capabilities.The MC-21 is positioned as a competitor to the Tu-214, with Aeroflot planning to purchase 339 MC-21s instead of the Tu-214. Despite delays, the project represents a major step in Russia's aviation industry, aiming to reduce reliance on foreign technology and establish a robust domestic aircraft manufacturing sector.

View: https://www.youtube.com/watch?v=fQmHKRv1o0k

This aircraft is set to be the Russia's answer to the Boeing 737 and the Airbus A320 due to its aircraft performance characteristics and cost-effectiveness. Its main advantages are advanced aerodynamics and the newest engines along with the extended application of composite materials.

- Joined

- Jul 3, 2024

- Messages

- 1,181

- Likes

- 1,764

View: https://www.youtube.com/watch?v=QiFcXAIx8Mc

The Il-76MD-90AE modification is a major overhaul of the well-proven Il-76MD military transport aircraft. The main designation of the aircraft is to transport and airdrop military and civil bulky cargoes, military equipment, including tanks and personnel.Maximum payload of the aircraft is 60 tons, it is equipped with modern, reliable engines with FADEC-type digital control system. The Il-76MD-90AE fully complies with the current ICAO requirements and can be operated around the world without restrictions.

Similar threads

Latest Replies

-

Indian Special Forces

- RDXChauhan

-

Indo-China Border & LAC

- RDXChauhan

-

Idiotic Musings from the West

- realsumo

-

-

Indian Economy

- Spacemarine

-

US: News & Discussions

- ezsasa

-

Hideous tactics of Evangelicals and Missionaries in India

- Hindaviswarajya

-

Islamic Extremism in India : News , Discussions & Updates.

- Hindaviswarajya