Unbelievable disaster. I thought out of 240, perhaps 10-30 might survive this kind of crach.

Condolence for the victims. Om Sadgatir Bhuyat

Unfortunately there were multi-level buildings in the way.

A decade back, i flew the 737 public simulators at Forum mall, Koramangala, Bengaluru & at Phoenix Market City mall in Kurla, Mumbai. It costed Rs 2,000 or 3,000 for 1 hour. For that i had to study the cockpit controls for few weeks. Regular public wouldn't care about it.

Numerous analysis vids are coming in, I watched many videos by professionals globally, civil & AF, active & retired. But very few explained some important cockpit contols & sub-systems.

Many airlines use cockpit camera. If Air India used it & if it survived the fire then it can give huge input.

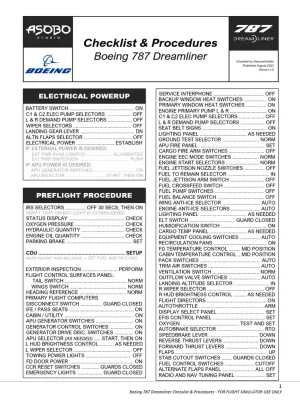

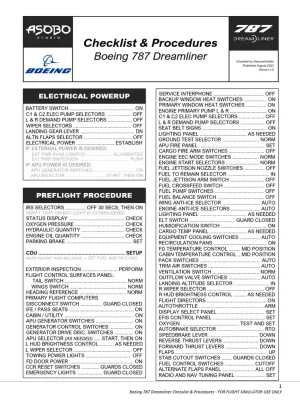

Pre-flight checklist includes everything we can imagine. It has become digital.

"Cold & dark start" videos of both sims & real jet are there on YouTube.

The pilot has to program the FMC (Fight Management Computer) before each flight about -

- source, route & destination

- weight carried / MTOW

- V1, V2, Vr

- weather conditions

- flight limits of RPM, speed, altitude, EGT (Exhaust Gas temp.), etc at take-off, flight.

OPTIMUM/AUTO options are avaiable for each parameter but although highly unlikely but THEORETICALLY, if pilot sets inacurate limits then it can be disastrous.

This might be a hypothetical example if full throttle is opened then EGT goes high, but EGT limit is lower then it might reduce thrust & lift. so FMC programming needs to be done carefully.

Landing gears were down, so the pilots started facing problems immediately after takeoff.

Landing gears were down, so the pilots started facing problems immediately after takeoff.

Bird strike would cause engine flame, shattering, not visible in both videos.

Airports have many security guards & perimeter cameras which can give clue into 2engine bird strike.

I wonder if it could be overloading issue. I think Air India allows more luggage per person.

But there is flight plan entry in FMC about weight to be carried + atmosphere conditions, etc to set the take off thrust & flaps setting required.

If Air India allowed more luggage but THEORETICALLY wrong data to pilot was passed for FMC entry then it can be a coordination failure.

If we see the runway take off clip from left side,

the flaps are down.

If we see the other video from right side, the

flaps might still be down, but due to poor quality video & flexible shape of 787 wing it appears narrow.

The 787 & all

airliners cockpit have manual flap lever, that too put into metal notches, need to lift the lever & reposition into another notch up/down, unlike fighter jets.

So AFAIK here the FCS won't retract the flaps, especially at low speeds.

Moreover

it is in the S/w to sound alarm if flaps not set properly at low speeds, stall detection, etc.

If the pilots accidentally retracted them then immediate alarm woud sound & they can correct the lever position & gain altitude.

Leading edge slats are also auto-deployed at low speeds.

Slat & flaps deployed at takeoff :

All spoilers up & flaps, slats down while landing :

Technically, if the speed-brake/spoiler is operated wrong then it can kill lift, but it has its settings for ground, takeoff, flight & is tied to FMC/FCS.

After it starts decending, It rolls slightly to right then left then centers.

So electrical & hydraullic power to operate was there, which are redundant.

Li-ion battery problem was fixed. It is for initial system start & said to last 15 mins fully charged.

The APU is started & has 2x generators.

Engines have their own 2x generators. Then APU is shut down.

1x surviving engine can make the plane take off, fly around & do emergency landing.

The lone survivor said that after few seconds of takeoff electricity went out for few seconds & some say RAT was deployed. This way if engines lost power & with RAT they were restarted then there wasn't enough time to regain altitude.

The lone survivor said that after few seconds of takeoff electricity went out for few seconds & some say RAT was deployed. This way if engines lost power & with RAT they were restarted then there wasn't enough time to regain altitude.

But -

- The cockpit overhead panel has separate switches & knobs for cabin utility & HVAC, even for cargo compartment.

- when diagram shows eletrical redundancies from 4 generators then how can both engines loose electricity?

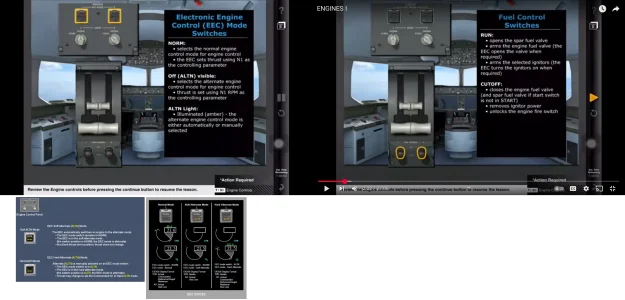

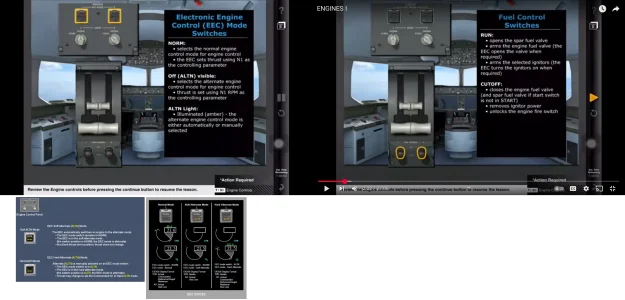

There is Electronic Engine Control or EEC also, After achieving sufficient N2 rotation, the EEC Is powered by its associated PMA, (Permanent Magnet Alternator).

It continiously monitors throttle, provides protection against flame-out during ecess rain, hail.

It monitors N1, N2, N3 spool speeds also & if RPM limit crossed then fuel flow would be reduced to lower the RPMs.

The EEC shuts down the engine only if RPM limiting fails & overspeed condition occurs.

If fuel-switch is accidentally shut off then EEC can electronically turn it & ignitors on.

There is TAP (Thrust Asymmetry Protection).

On ground it'll shut down engine if above idle speed and not decelerating normally.

During take-off if 1 engine fails then TAP reduces thrust on surviving engine to safeguard rudder/yaw control.

TAP is only available when flight controls are in normal mode.

The Airborne Vibration And Monitoring System tracks engine vibration levels (

Rotor Imbalance), which is displayed on the secondary engine display, including the source. i.e.,

N1,

N2 or

N3.

Engine Failure Alert System - During takeoff (When the engine is producing less than the commanded thrust from 65 knots to slightly below V1), a time critical warning happens - A siren followed by voice annunciation ENGINE FAIL; Illumination of the red MASRER WARNING lights; PFD and HUD warning message ENG FAIL.

Poor quality fuel? The petroleum companies need to follow ISO & other standards, quality inspections. This violation would affect multiple jets & would be a huge scam.

Some say maintenance issues, clogged fuel lines/pumps/valves/filter, etc. But everything is redundant -

- fuel pumps (LP, HP),

- filters (LP, HP),

- igniters,

- combustion chambers are annular,

- fuel lines are redundantly cross fed too. AFAIK, IMO 1 or 2 pumps only could have clogging but will be taken care of by redundancy.

Last but not least, if the air data sensors are clogged then it can be big problem. Although there are multiple of them for redundancy but accidents due to them have happened.

Last but not least, if the air data sensors are clogged then it can be big problem. Although there are multiple of them for redundancy but accidents due to them have happened.