You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese Economy Watch (5 Viewers)

- Thread starter rockdog

- Start date

More options

Who Replied?not related to this thread

true but you can not understand where is going the economy unless you have higher knowledge you think China is all flowers and next USA, I have economic reasons to know that is not true, and those economic reasons confirm my spiritual reasons, so I am not a Mexico uber alles, but you are a China uber alles.

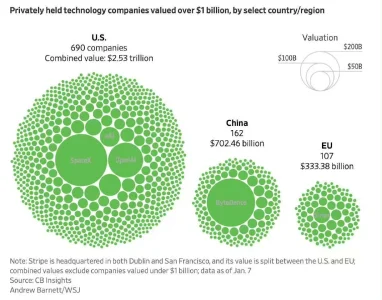

View attachment 38465

just study the economy of the EU since 1955 and see the trend

you will understand trump but as long you do not get you will think China will rule, remember WWII was planned

View attachment 38466

View attachment 38467

- Joined

- Jul 1, 2024

- Messages

- 4,793

- Likes

- 25,174

View: https://twitter.com/crmiller1/status/1930554786899697910?s=19

We find that Chinese firms have made much more progress winning business with Apple in lower-tech, lower-profit-margin segments of the supply chain, while foreign firms (including those producing in China) generally remain well represented in higher-tech, higher-margin segments of the supply chain. In other words, the parts of the Apple supply chain that have become meaningfully more “Chinese” in ownership tend to be the more commoditized segments. These are generally also the segments for which Apple has taken some steps in recent years to open factories in other locations, such as Southeast Asia and India.

In other words after nearly 16-17 years of assembling iPhones in China, China owned & operated companies contribution to components in an iPhone was low tech low margin commoditised items whereas the real cream in terms of high value high margin components were usually Japanese, US, Taiwanese & South Korean owned companies operating out of China.

So much for China being the manufacturing giant as opposed to being the assembly hub of the world.

But Huawei's doing a good job forcing Apple out of the cellphone market in China though how much of the components going into a Huawei phone has components from Chinese owned & operated companies itself is a huge question mark.

If Apple is any indicator, then those Chinese owned & operated companies would be involved in the same low tech low margin commoditised items except for the SMC which would be of Huawei make for obvious reasons .

View: https://twitter.com/crmiller1/status/1930554786899697910?s=19

In other words after nearly 16-17 years of assembling iPhones in China, China owned & operated companies contribution to components in an iPhone was low tech low margin commoditised items whereas the real cream in terms of high value high margin components were usually Japanese, US, Taiwanese & South Korean owned companies operating out of China.

So much for China being the manufacturing giant as opposed to being the assembly hub of the world.

But Huawei's doing a good job forcing Apple out of the cellphone market in China though how much of the components going into a Huawei phone has components from Chinese owned & operated companies itself is a huge question mark.

If Apple is any indicator, then those Chinese owned & operated companies would be involved in the same low tech low margin commoditised items except for the SMC which would be of Huawei make for obvious reasons .

Dude, i think you are somehow obsessed with iPhone and iPhone supply chain, but please also notice that, iPhone supply chain is no more a top1 topic in our industry here in China.

There are two reasons:

1. Forced by US government, some high tech components from Chinese companies, are not allowed became suppliers:

U.S. Lawmakers Warn Apple about the use of Memory Chips from China's Yangtze Memory Technologies for the iPhone 14

But see how high tech it is:

Samsung Electronics has signed a contract with Yangtze Memory Technologies Co. (YMTC) which will allow it to use the Chinese semiconductor company's bonding technology in the production of its 400-layer NAND flash memory.

Tech war: Ofilm, formerly blacklisted by US and dumped by Apple as supplier, is contractor for Huawei’s Mate 60 phone

Dumped Apple supplier Ofilm gets lifeline as Huawei contractor

Ofilm, which was temporarily put on a US trade blacklist, is reportedly producing most camera modules used in Huawei’s new flagship smartphones.

There are many other cases, i have no time to mention it.

2. Lots of Chinese brands are already had higher end product and pricing than iPhone with more progressive technology. like Foldable screen, and 120w GaN charger, which iPhone didn't applied yet, and they are backed by high tech local suppliers.

PS. GaN is also the key component for AESA radar, and China almost control 100% the them, i heard some nation just bought 10000 GaN chargers from Shenzhen Huaqiangbei market, to get the materials for their radar production.

View: https://x.com/Trolling_isart/status/1789891129493905611?t=wgrZcaS77dqj1nV0zE9ucQ&s=19

View: https://x.com/feni_book/status/1902704264956264685?t=4CDrq-YfKFOaVhcUsnB4Yg&s=19

Last edited:

- Joined

- Jul 1, 2024

- Messages

- 4,793

- Likes

- 25,174

Dude, i think you are somehow obsessed with iPhone and iPhone supply chain, but please also notice that, iPhone supply chain is no more a top1 topic in our industry here in China.

It's still the number one PREMIUM brand across the world . China's not the entire world , you know. But I can understand your pain !

Moreover that article was published by an American Institute . You have a problem with it ? You want to refute facts with your own ? Feel free to do so on Twitter . The co author is Chris Miller . He's an American.

There are two reasons:

1. Forced by US government, some high tech components from Chinese companies, are not allowed became suppliers:

U.S. Lawmakers Warn Apple about the use of Memory Chips from China's Yangtze Memory Technologies for the iPhone 14

But see how high tech it is:

Samsung Electronics has signed a contract with Yangtze Memory Technologies Co. (YMTC) which will allow it to use the Chinese semiconductor company's bonding technology in the production of its 400-layer NAND flash memory.

So here too , you don't have an innovative Chinese company but a JV with Samsung , much like the article I quoted points out.

Meanwhile excerpts from the Yahoo article you've quoted.

Founded in 2016 and headquartered in Wuhan, China, YMTC is a subsidiary of Tsinghua Unigroup, which is backed by the Chinese government.

Although YMTC significantly trails behind global memory semiconductor corporations such as Samsung Electronics and SK Hynix in terms of market share, it is quickly catching up with South Korean firms, recently starting mass production of 294-layer NAND flash memory," the site explains.

Besides with your track record of having backdoors in all your electronic devices who exactly trusts you ?!

Tech war: Ofilm, formerly blacklisted by US and dumped by Apple as supplier, is contractor for Huawei’s Mate 60 phone

Dumped Apple supplier Ofilm gets lifeline as Huawei contractor

Ofilm, which was temporarily put on a US trade blacklist, is reportedly producing most camera modules used in Huawei’s new flagship smartphones.www.scmp.com

There are many other cases, i have no time to mention it.

Apple dumped OFilm because of usage of forced labour from Xinjiang which is prohibited by Apple's internal policies & by US Federal Law. You should read up more on the issue or better still try not concealing the truth .

2. Lots of Chinese brands are already had higher end product and pricing than iPhone with more progressive technology. like Foldable screen, and 120w GaN charger, which iPhone didn't applied yet, and they are backed by high tech local suppliers.

PS. GaN is also the key component for AESA radar, and China almost control all the them, i heard some nation just bought 10000 GaN chargers from Huaqiangbei market, to get the material for their radar industry.

View: https://x.com/Trolling_isart/status/1789891129493905611?t=wgrZcaS77dqj1nV0zE9ucQ&s=19

View: https://x.com/feni_book/status/1902704264956264685?t=4CDrq-YfKFOaVhcUsnB4Yg&s=19

Good development ! I for one want Huawei & other Chinese cell phone OEMs to drive Apple out of business from China & then the rest of the world.

How else will the much anticipated war over Taiwan between the US & China happen ? All these incidents will serve as mini triggers which aggregate into a huge sum to trigger off the conflict .

Last edited:

It's still the number one PREMIUM brand across the world . China's not the entire world , you know. But I can understand your pain !

China + India = 2.8B population, and Chinese brands of phone have 80% share i think, they still have lots of space for high end types for growth, thank you dude!

So here too , you don't have an innovative Chinese company but a JV with Samsung , much like the article I quoted points out.

Nop, it based the Xtacking platform, YMTC developed, the JV with Sunsumg was for selling to US market with restrictions. For local market, it uses own brand Zhitai.

YMTC’s Xtacking 3.0 – Not what TechInsights was expecting to see

YMTC’s Xtacking 3.0 – Not what TechInsights was expecting to see | TechInsights

Memory Blog

Apple dumped OFilm because of usage of forced labour from Xinjiang which is prohibited by Apple's internal policies & by US Federal Law. You should read up more on the issue or better still try not concealing the truth .

Well, it's excuse, just like Khalistan stuff to shit India. USA is good at it.

- Joined

- Jul 1, 2024

- Messages

- 4,793

- Likes

- 25,174

As of the present yes especially for a country whose PCI is ~ 2500 USD . They value cheap phones due to their affordability . As their income improves they go for more premium brands.China + India = 2.8B population, and Chinese brands of phone have 80% share i think, they still have lots of space for high end types for growth, thank you dude!

Besides who knows what the future is going to be especially with Great Helmsman 2.0 & his obsession to go down in Chinese history as the great unifier of the glorious Chinese nation ?

With Chinese state subsidies no doubt running into billions of USD . Congratulations !Nop, it based the Xtacking platform, YMTC developed, the JV with Sunsumg was for selling to US market with restrictions.

YMTC’s Xtacking 3.0 – Not what TechInsights was expecting to see

YMTC’s Xtacking 3.0 – Not what TechInsights was expecting to see | TechInsights

Memory Blogwww.techinsights.com

Last time I checked we didn't fight a war with the US in 1962 nor did we lose our soldiers to the US or kill theirs in Galwan . The US isn't our friend but it isn't our enemy either. Not as of the present which we cannot & will not say about the Han.Well, it's excuse, just like Khalistan stuff to shit India. USA is good at it.

- Joined

- Jul 3, 2024

- Messages

- 790

- Likes

- 374

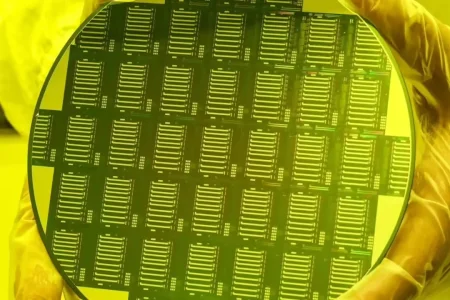

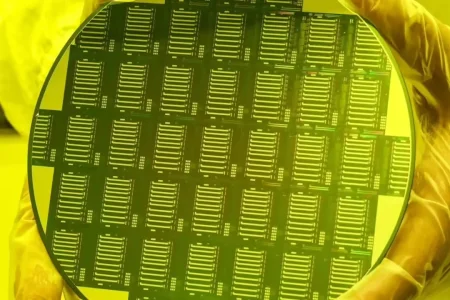

On June 6th, Shanghai Jiao Tong University Wuxi Photonics Chip Research Institute (CHIPX) announced a significant moment today: On June 5th, the first 6-inch thin-film lithium niobate photonic chip wafer was launched in the first domestic photonic chip pilot production line. At the same time, it achieved large-scale production of high-performance thin-film lithium niobate modulator chips with ultra-low loss and ultra-high bandwidth, and the key technical indicators reached the international advanced level.

CHIPX's official statement indicates that this breakthrough achievement marks China's historic leap from "technology catch-up" to "industry leadership" in the field of high-end optoelectronic core devices. Relying on the pilot production platform, the research institute will join hands with partners in the industrial chain to promote the process of large-scale mass production, build a full-chain capability of "technology research and development - process verification - large-scale mass production", and further enhance the international competitiveness of independent and controllable quantum technology.

Photonic quantum chips are the core hardware carriers of photonic quantum computing. Their industrialization process will promote China's realization of independent control in the field of quantum information and is also a strategic support for seizing the commanding heights of global quantum technology competition. Previously, due to the lack of a common key process technology platform, China's photonic quantum technology faced the predicament of "difficulty in mass-producing laboratory achievements", which was a "bottleneck" problem restricting the development of the industry. However, the launch of the photonic chip pilot production line has become the key to breaking the deadlock.

In December 2022, the Wuxi Institute of Photonic Chips of Shanghai Jiao Tong University initiated the construction of China's first photonic chip pilot production line. In September 2024, the photonic chip pilot production line integrating the research and development, design, processing and application of photonic chips was officially put into use. Now, the first wafer has successfully rolled off the production line, and the pilot platform has achieved mass production.

As a high-performance optoelectronic material, thin-film lithium niobate has advantages such as ultrafast electro-optic effects, high bandwidth, and low power consumption, and shows great potential in fields such as 5G communication and quantum computing. However, due to the high brittleness of thin-film lithium niobate materials, the preparation of large-sized thin-film lithium niobate wafers has always been regarded as a challenge by the industry, especially in the mass production process, which faces three major problems: controlling the nanoscale processing accuracy, ensuring the uniformity of thin-film deposition, and regulating the consistency of etching rate.

Based on its independently built first domestic photonic chip pilot line, the CHIPX process team has introduced over 110 sets of top international CMOS process equipment, covering the entire closed-loop process of thin-film lithium niobate wafers from photolithography, thin film deposition, etching, wet process, cutting, measurement to packaging. By innovatively developing the collaborative adaptation technology of chip design, process solutions and equipment systems, we have successfully broken through the entire manufacturing process from photolithography patterning, precision etching, thin film deposition to packaging and testing, achieving a breakthrough in the integrated process of wafer-level photonic chips.

Relying on the advanced nano-scale processing equipment and rapid process iteration capabilities of the pilot platform, the process team, through extensive process verification and optimization, systematically solved the key technical bottlenecks of wafer-level photonic chip integration by combining deep ultraviolet (DUV) lithography and thin film etching processes: achieving 110nm high-precision waveguide etching on 6-inch lithium niobate wafers; The cross-scale integration of highly uniform, nanoscale waveguides and complex high-performance electrode structures was accomplished through step-by-step (i-line) lithography, reaching the top-level manufacturing process level.

Meanwhile, through the collaborative design innovation of materials and devices, the process team has achieved a leapfrog breakthrough in performance while taking into account high integration, and all key indicators are leading comprehensively:

The modulation bandwidth has exceeded 110GHz, breaking through the bandwidth bottleneck of international high-speed optical interconnection

The insertion loss is less than 3.5dB and the waveguide loss is less than 0.2dB/cm, significantly improving the optical transmission efficiency

The modulation efficiency is less than 1.9 V · cm, and the electro-optical conversion efficiency has been significantly optimized

Relying on the pilot production line platform and the mass production capacity of 12,000 wafers per year, the research institute will provide industrial partners with "low-cost", "rapid iteration" and "large-scale mass production" solutions.

IT Home learned from CHIPX's announcement that in the third quarter of this year, the research institute will release the PDK process design package. The core process parameters and device models of the high-performance thin-film lithium niobate modulator chip have been fully incorporated and are now open for sharing. This version of PDK not only integrates basic component models such as passive couplers, beam splitters, waveguide arrays, active thermal phase shifters, and electro-optic modulators, but also covers a multi-physics field collaborative simulation module, establishing a standardized photonic chip design system.

CHIPX's official statement indicates that this breakthrough achievement marks China's historic leap from "technology catch-up" to "industry leadership" in the field of high-end optoelectronic core devices. Relying on the pilot production platform, the research institute will join hands with partners in the industrial chain to promote the process of large-scale mass production, build a full-chain capability of "technology research and development - process verification - large-scale mass production", and further enhance the international competitiveness of independent and controllable quantum technology.

Photonic quantum chips are the core hardware carriers of photonic quantum computing. Their industrialization process will promote China's realization of independent control in the field of quantum information and is also a strategic support for seizing the commanding heights of global quantum technology competition. Previously, due to the lack of a common key process technology platform, China's photonic quantum technology faced the predicament of "difficulty in mass-producing laboratory achievements", which was a "bottleneck" problem restricting the development of the industry. However, the launch of the photonic chip pilot production line has become the key to breaking the deadlock.

In December 2022, the Wuxi Institute of Photonic Chips of Shanghai Jiao Tong University initiated the construction of China's first photonic chip pilot production line. In September 2024, the photonic chip pilot production line integrating the research and development, design, processing and application of photonic chips was officially put into use. Now, the first wafer has successfully rolled off the production line, and the pilot platform has achieved mass production.

As a high-performance optoelectronic material, thin-film lithium niobate has advantages such as ultrafast electro-optic effects, high bandwidth, and low power consumption, and shows great potential in fields such as 5G communication and quantum computing. However, due to the high brittleness of thin-film lithium niobate materials, the preparation of large-sized thin-film lithium niobate wafers has always been regarded as a challenge by the industry, especially in the mass production process, which faces three major problems: controlling the nanoscale processing accuracy, ensuring the uniformity of thin-film deposition, and regulating the consistency of etching rate.

Based on its independently built first domestic photonic chip pilot line, the CHIPX process team has introduced over 110 sets of top international CMOS process equipment, covering the entire closed-loop process of thin-film lithium niobate wafers from photolithography, thin film deposition, etching, wet process, cutting, measurement to packaging. By innovatively developing the collaborative adaptation technology of chip design, process solutions and equipment systems, we have successfully broken through the entire manufacturing process from photolithography patterning, precision etching, thin film deposition to packaging and testing, achieving a breakthrough in the integrated process of wafer-level photonic chips.

Relying on the advanced nano-scale processing equipment and rapid process iteration capabilities of the pilot platform, the process team, through extensive process verification and optimization, systematically solved the key technical bottlenecks of wafer-level photonic chip integration by combining deep ultraviolet (DUV) lithography and thin film etching processes: achieving 110nm high-precision waveguide etching on 6-inch lithium niobate wafers; The cross-scale integration of highly uniform, nanoscale waveguides and complex high-performance electrode structures was accomplished through step-by-step (i-line) lithography, reaching the top-level manufacturing process level.

Meanwhile, through the collaborative design innovation of materials and devices, the process team has achieved a leapfrog breakthrough in performance while taking into account high integration, and all key indicators are leading comprehensively:

The modulation bandwidth has exceeded 110GHz, breaking through the bandwidth bottleneck of international high-speed optical interconnection

The insertion loss is less than 3.5dB and the waveguide loss is less than 0.2dB/cm, significantly improving the optical transmission efficiency

The modulation efficiency is less than 1.9 V · cm, and the electro-optical conversion efficiency has been significantly optimized

Relying on the pilot production line platform and the mass production capacity of 12,000 wafers per year, the research institute will provide industrial partners with "low-cost", "rapid iteration" and "large-scale mass production" solutions.

IT Home learned from CHIPX's announcement that in the third quarter of this year, the research institute will release the PDK process design package. The core process parameters and device models of the high-performance thin-film lithium niobate modulator chip have been fully incorporated and are now open for sharing. This version of PDK not only integrates basic component models such as passive couplers, beam splitters, waveguide arrays, active thermal phase shifters, and electro-optic modulators, but also covers a multi-physics field collaborative simulation module, establishing a standardized photonic chip design system.

- Joined

- Jul 3, 2024

- Messages

- 1,714

- Likes

- 2,290

ASML the key target

Brekelmans’ warning comes amid an intense technology war between China and the West — one that has intensified over the past three years amid efforts by the United States to cut Beijing off from cutting-edge semiconductor technology

Dutch Minister Says China 'Biggest Threat' to Chip Tech Secrets

Dutch Defence Minister Ruben Brekelmans warned that China was ‘intensifying’ efforts — statements that got a seething response from Beijing

www.asiafinancial.com

www.asiafinancial.com

- Joined

- Jun 27, 2024

- Messages

- 962

- Likes

- 6,879

Good article about Chinese moving to Congo for economic opportunities.

"In Congo, Chinese Hustlers Seek Relief From Pressures Back Home"

"The Miranda Hotel is owned and run by Hannah Chen, 40, from Fujian in southern China. Her family owns dozens of businesses across the city, from a quarry to a brick factory, an electronics store, a tire dealer, a hospital and a burger restaurant. All of them primarily service Chinese companies and immigrants.

“I stay overseas because it’s too competitive back home. No one would employ me with this level of education,” said Chen, who never completed middle school. “There are more opportunities overseas.”

Back home, the chances of financial success are even tougher because of an economic slowdown and intense competition.

The Chinese government has said that as of February, one in six young people was unemployed. The country’s growth has slowed in recent years as it deals with an aging population and a protracted downturn in its real estate sector. Those problems have been compounded by the impact of US President Donald Trump’s tariffs.

Some young Chinese people have responded by “lying flat,” a movement that rejects the culture of long hours and hard work that’s often glorified in China. Others, like Li, have sought success overseas. He’s one of thousands of Chinese businesspeople who have made Kolwezi the target of their ambitions, and these days the city is littered with Chinese supermarkets, casinos, karaoke joints, auto shops and even medical clinics.

."

"In Congo, Chinese Hustlers Seek Relief From Pressures Back Home"

"The Miranda Hotel is owned and run by Hannah Chen, 40, from Fujian in southern China. Her family owns dozens of businesses across the city, from a quarry to a brick factory, an electronics store, a tire dealer, a hospital and a burger restaurant. All of them primarily service Chinese companies and immigrants.

“I stay overseas because it’s too competitive back home. No one would employ me with this level of education,” said Chen, who never completed middle school. “There are more opportunities overseas.”

Back home, the chances of financial success are even tougher because of an economic slowdown and intense competition.

The Chinese government has said that as of February, one in six young people was unemployed. The country’s growth has slowed in recent years as it deals with an aging population and a protracted downturn in its real estate sector. Those problems have been compounded by the impact of US President Donald Trump’s tariffs.

Some young Chinese people have responded by “lying flat,” a movement that rejects the culture of long hours and hard work that’s often glorified in China. Others, like Li, have sought success overseas. He’s one of thousands of Chinese businesspeople who have made Kolwezi the target of their ambitions, and these days the city is littered with Chinese supermarkets, casinos, karaoke joints, auto shops and even medical clinics.

."

- Joined

- Jul 1, 2024

- Messages

- 4,793

- Likes

- 25,174

Good article about Chinese moving to Congo for economic opportunities.

"In Congo, Chinese Hustlers Seek Relief From Pressures Back Home"

"The Miranda Hotel is owned and run by Hannah Chen, 40, from Fujian in southern China. Her family owns dozens of businesses across the city, from a quarry to a brick factory, an electronics store, a tire dealer, a hospital and a burger restaurant. All of them primarily service Chinese companies and immigrants.

“I stay overseas because it’s too competitive back home. No one would employ me with this level of education,” said Chen, who never completed middle school. “There are more opportunities overseas.”

Back home, the chances of financial success are even tougher because of an economic slowdown and intense competition.

The Chinese government has said that as of February, one in six young people was unemployed. The country’s growth has slowed in recent years as it deals with an aging population and a protracted downturn in its real estate sector. Those problems have been compounded by the impact of US President Donald Trump’s tariffs.

Some young Chinese people have responded by “lying flat,” a movement that rejects the culture of long hours and hard work that’s often glorified in China. Others, like Li, have sought success overseas. He’s one of thousands of Chinese businesspeople who have made Kolwezi the target of their ambitions, and these days the city is littered with Chinese supermarkets, casinos, karaoke joints, auto shops and even medical clinics.

."

Video of Chinese Manager Beating African Workers Sparks Racism Debate

This is not the first time that such incidents have been reported. In April last year, news agency ANI carried a report that highlighted the ill treatment of African workers by Chinese project managers.

Pretty soon we can expect behavior like this to be normalised & then one fine day the Africans get into a murderous frenzy & massacre the Chinese there.

Old story with the Chinese in SE Asia where they're a much loved community. Soon the Africans will get to love the Chinese too

Additional benefits include Chinese men there getting women so what if they're African. Given the shortage of women back home & the fact that most either don't want to marry or are extremely choosy or don't want to have children, chances of males ending up without females are high.

Such men are known as "Leftover Men " in China . @rockdog is one of them.

- Joined

- Jul 3, 2024

- Messages

- 790

- Likes

- 374

Good article about Chinese moving to Congo for economic opportunities.

"In Congo, Chinese Hustlers Seek Relief From Pressures Back Home"

"The Miranda Hotel is owned and run by Hannah Chen, 40, from Fujian in southern China. Her family owns dozens of businesses across the city, from a quarry to a brick factory, an electronics store, a tire dealer, a hospital and a burger restaurant. All of them primarily service Chinese companies and immigrants.

“I stay overseas because it’s too competitive back home. No one would employ me with this level of education,” said Chen, who never completed middle school. “There are more opportunities overseas.”

Back home, the chances of financial success are even tougher because of an economic slowdown and intense competition.

The Chinese government has said that as of February, one in six young people was unemployed. The country’s growth has slowed in recent years as it deals with an aging population and a protracted downturn in its real estate sector. Those problems have been compounded by the impact of US President Donald Trump’s tariffs.

Some young Chinese people have responded by “lying flat,” a movement that rejects the culture of long hours and hard work that’s often glorified in China. Others, like Li, have sought success overseas. He’s one of thousands of Chinese businesspeople who have made Kolwezi the target of their ambitions, and these days the city is littered with Chinese supermarkets, casinos, karaoke joints, auto shops and even medical clinics.

."

Make Congo great again

US Inaction Is Ceding the Global Nuclear Market to China and Russia

www.wilsoncenter.org

www.wilsoncenter.org

US Inaction Is Ceding the Global Nuclear Market to China and Russia

- Joined

- Jul 3, 2024

- Messages

- 1,714

- Likes

- 2,290

An abandoned ship full of EVs is burning in the Pacific

Mack DeGeurin

Sat, June 7, 2025 at 5:38 AM GMT+9·4 min read

Smoke rises from the Morning Midas.

A cargo ship transporting 3,000 cars was abandoned in the middle of the Pacific Ocean on Tuesday after a massive fire broke out. As of Friday, the ship was still burning. The blaze may have been fueled by the vehicles’ lithium-ion batteries, which are notoriously difficult to extinguish once ignited.

The ship, named Morning Midas, was reportedly carrying 3,000 cars on a journey from Yantai, China to Lázaro Cárdenas, Mexico. Of those vehicles, about 750 were fully electric or partial hybrids, powered at least in part by large lithium‑ion batteries that can short‑circuit and ignite extremely hot fires. Although the exact cause has yet to be determined, the Morning Midas crew reported smoke rising from the deck around midnight on Tuesday.

A representative from Zodiac Maritime, a UK-based ship manager overseeing the vessel, told The Register that the 22 sailors on board responded to the fire on Tuesday and attempted to extinguish it using the available onboard fire suppression systems. It wasn’t enough. As the blaze grew out of control, the crew reportedly issued a distress call and abandoned the ship in lifeboats. A nearby merchant vessel responded and rescued all 22 sailors, according to a statement released by the U.S. Coast Guard.

As for the Morning Midas, it remains afloat and burning in the middle of the Pacific Ocean, approximately 304 miles south of Adak, Alaska. It’s unclear what makes or models of cars were aboard—or whether any of them will be recoverable.

In a statement sent to Popular Science, Zodiac Maritime said the decision was made to prioritize safety crew and abandon the vessel due to the intensity of the fire. Zodiac has appointed salvage company Resolve Marine to respond to the ongoing fire. A separate team of salvage specialists are expected to arrive on the scene by June 9. Zodiac says it’s continuing to monitor the Midas’ status via its onboard satellite-connected systems.

“As the search and rescue portion of our response concludes, our crews are working closely with the vessel’s manager, Zodiac Maritime, to determine the disposition of the vessel,” US Coast Guard Seventeenth District Commander Rear Admiral Megan Dean said in a statement. “We are grateful for the selfless actions of the three nearby vessels who assisted in the response and the crew of motor vessel Cosco Hellas, who helped save 22 lives.”

Related: [Electric vehicle fires are rare, but challenging to extinguish]

What makes EV battery fires so hard to put out

You’ve likely seen images of firefighters struggling to put out fires in Teslas and other large EVs. While EVs are statistically less likely to catch fire than vehicles with internal combustion engines, the fires that do occur are significantly more difficult to extinguish. That’s due to a phenomenon known as thermal runaway. The large lithium-ion batteries that power EVs can short-circuit, triggering a chain reaction that eventually leads to ignition.

Thermal runaway can take days, or even weeks, to manifest. But once ignited, these fires burn much hotter than those caused by traditional internal combustion engines. They can also reignite after being extinguished, making them especially challenging for firefighters to manage.

ISTANBUL, TURKIYE - OCTOBER 06: Six Tesla electric cars burn on the trailer of the moving lorry carrying them after one of them catches on fire due to unknown reasons in Istanbul, Turkiye on October 06, 2023. (Photo by Muhammed Gencebay Gur/Anadolu Agency via Getty Images)

Tesla electric cars burn on the trailer of the moving truck after one of them catches on fire due to unknown reasons in Istanbul, Turkey. Image: Muhammed Gencebay Gur/Anadolu Agency via Getty Images Anadolu

Cargo ships are a perfect breeding ground for potentially dangerous fires. They’re often tightly packed with vehicles and have limited ventilation, meaning a fire in one vehicle can quickly spread to others. And while ships are typically equipped with some firefighting systems, those measures may be insufficient once a blaze spreads across multiple vehicles.

In 2022, a cargo ship transporting 4,000 vehicles caught fire in the Atlantic Ocean and eventually sank. Just a year later, another ship carrying around 3,000 vehicles caught fire off the Dutch coast. That incident killed one person and injured several others.

EV batteries are getting safer

Carmakers and battery suppliers are making efforts to improve the durability and reduce the risk of lithium ion fires. Just this week, Texas-based Alkegen, a major supplier of cell spacers used in batteries, announced commercial production of a new type of aerogel insulation they say can protect EV batteries from thermal runaway. Other companies have made improvements in monitoring systems to keep tabs on a battery’s health and more int

www.yahoo.com

www.yahoo.com

Mack DeGeurin

Sat, June 7, 2025 at 5:38 AM GMT+9·4 min read

Smoke rises from the Morning Midas.

A cargo ship transporting 3,000 cars was abandoned in the middle of the Pacific Ocean on Tuesday after a massive fire broke out. As of Friday, the ship was still burning. The blaze may have been fueled by the vehicles’ lithium-ion batteries, which are notoriously difficult to extinguish once ignited.

The ship, named Morning Midas, was reportedly carrying 3,000 cars on a journey from Yantai, China to Lázaro Cárdenas, Mexico. Of those vehicles, about 750 were fully electric or partial hybrids, powered at least in part by large lithium‑ion batteries that can short‑circuit and ignite extremely hot fires. Although the exact cause has yet to be determined, the Morning Midas crew reported smoke rising from the deck around midnight on Tuesday.

A representative from Zodiac Maritime, a UK-based ship manager overseeing the vessel, told The Register that the 22 sailors on board responded to the fire on Tuesday and attempted to extinguish it using the available onboard fire suppression systems. It wasn’t enough. As the blaze grew out of control, the crew reportedly issued a distress call and abandoned the ship in lifeboats. A nearby merchant vessel responded and rescued all 22 sailors, according to a statement released by the U.S. Coast Guard.

As for the Morning Midas, it remains afloat and burning in the middle of the Pacific Ocean, approximately 304 miles south of Adak, Alaska. It’s unclear what makes or models of cars were aboard—or whether any of them will be recoverable.

In a statement sent to Popular Science, Zodiac Maritime said the decision was made to prioritize safety crew and abandon the vessel due to the intensity of the fire. Zodiac has appointed salvage company Resolve Marine to respond to the ongoing fire. A separate team of salvage specialists are expected to arrive on the scene by June 9. Zodiac says it’s continuing to monitor the Midas’ status via its onboard satellite-connected systems.

“As the search and rescue portion of our response concludes, our crews are working closely with the vessel’s manager, Zodiac Maritime, to determine the disposition of the vessel,” US Coast Guard Seventeenth District Commander Rear Admiral Megan Dean said in a statement. “We are grateful for the selfless actions of the three nearby vessels who assisted in the response and the crew of motor vessel Cosco Hellas, who helped save 22 lives.”

Related: [Electric vehicle fires are rare, but challenging to extinguish]

What makes EV battery fires so hard to put out

You’ve likely seen images of firefighters struggling to put out fires in Teslas and other large EVs. While EVs are statistically less likely to catch fire than vehicles with internal combustion engines, the fires that do occur are significantly more difficult to extinguish. That’s due to a phenomenon known as thermal runaway. The large lithium-ion batteries that power EVs can short-circuit, triggering a chain reaction that eventually leads to ignition.

Thermal runaway can take days, or even weeks, to manifest. But once ignited, these fires burn much hotter than those caused by traditional internal combustion engines. They can also reignite after being extinguished, making them especially challenging for firefighters to manage.

ISTANBUL, TURKIYE - OCTOBER 06: Six Tesla electric cars burn on the trailer of the moving lorry carrying them after one of them catches on fire due to unknown reasons in Istanbul, Turkiye on October 06, 2023. (Photo by Muhammed Gencebay Gur/Anadolu Agency via Getty Images)

Tesla electric cars burn on the trailer of the moving truck after one of them catches on fire due to unknown reasons in Istanbul, Turkey. Image: Muhammed Gencebay Gur/Anadolu Agency via Getty Images Anadolu

Cargo ships are a perfect breeding ground for potentially dangerous fires. They’re often tightly packed with vehicles and have limited ventilation, meaning a fire in one vehicle can quickly spread to others. And while ships are typically equipped with some firefighting systems, those measures may be insufficient once a blaze spreads across multiple vehicles.

In 2022, a cargo ship transporting 4,000 vehicles caught fire in the Atlantic Ocean and eventually sank. Just a year later, another ship carrying around 3,000 vehicles caught fire off the Dutch coast. That incident killed one person and injured several others.

EV batteries are getting safer

Carmakers and battery suppliers are making efforts to improve the durability and reduce the risk of lithium ion fires. Just this week, Texas-based Alkegen, a major supplier of cell spacers used in batteries, announced commercial production of a new type of aerogel insulation they say can protect EV batteries from thermal runaway. Other companies have made improvements in monitoring systems to keep tabs on a battery’s health and more int

An abandoned ship full of EVs is burning in the Pacific

A cargo ship transporting 3,000 cars was abandoned in the middle of the Pacific Ocean on Tuesday after a massive fire broke out. As of Friday, the ship was still burning. The blaze may have been fueled by the vehicles’ lithium-ion batteries, which are notoriously difficult to extinguish once...

Fascism by commie chinese military and police against local farmers due to worsening water crisis and land acquisition.

View: https://x.com/songpinganq/status/1931420248265343038?t=OSxPjWrEVdcXWAU9yJiUhg&s=19

View: https://x.com/songpinganq/status/1931420248265343038?t=OSxPjWrEVdcXWAU9yJiUhg&s=19

Chinese child abuse in school.

View: https://x.com/bxieus/status/1931072536348852579?t=HfiIAbp1w2F6jF3FS7STrw&s=19

View: https://x.com/bxieus/status/1931072536348852579?t=HfiIAbp1w2F6jF3FS7STrw&s=19

Chinese child abuse in school.

View: https://x.com/bxieus/status/1931072536348852579?t=HfiIAbp1w2F6jF3FS7STrw&s=19

It used to be like that in india when we were studying in school . Once our teacher beat us for no reason with stick just to release his frustration. The revenge was taken by some people wearing helmet at a dark street

Latest Replies

-

Operation Sindoor & Aftermath

- Savageking456

-

Air India AI 171 Crash in Ahmedabad

- shiphone

-

Chinese Economy Watch

- E-195

-

Failed Terrorist Beggar State of Pakistan: Idiotic Musings

- The Juggernaut

-

Idiotic Musings from the West

- Miss Firing

-

Indian Economy

- Miss Firing

-

Indian Special Forces

- COLDHEARTED AVIATOR

-

Indian Army Aviation

- KAB7777

-

Indian Navy Developments & Discussions

- snakeeyes07