- Joined

- Jul 1, 2024

- Messages

- 4,793

- Likes

- 25,174

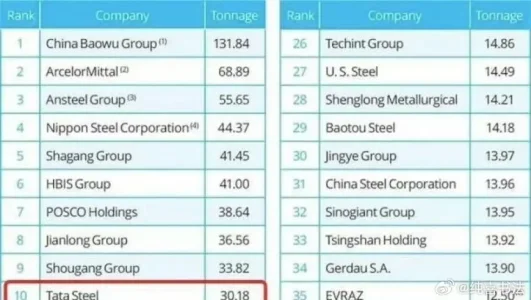

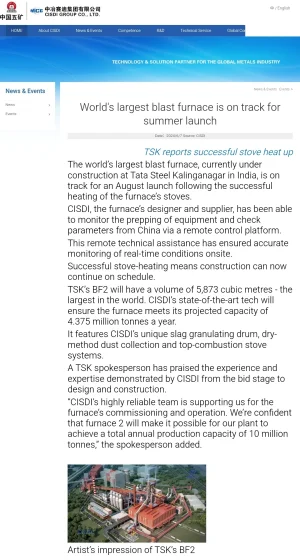

There are 2 phases to the project. One was the blast furnace commissioned in 2017 by the said Chinese company & another one last month. As far as those photographs go is there a time stamp on them ?View attachment 11188

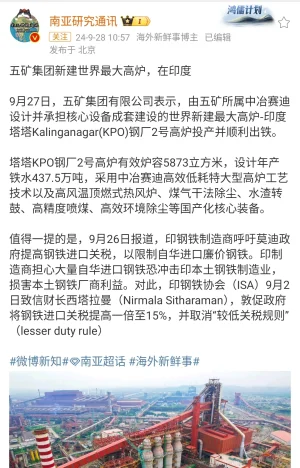

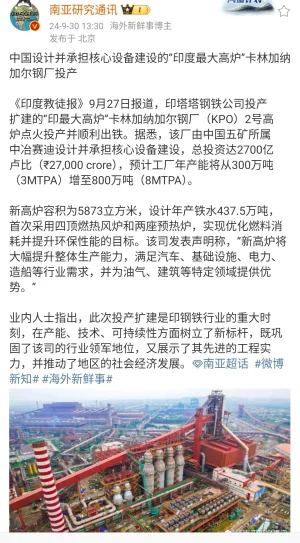

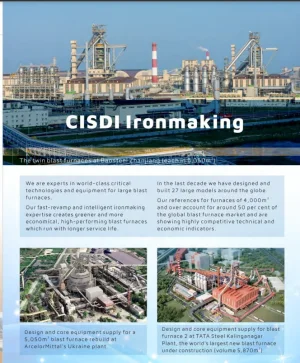

I saw the Chinese text, and it was confirmed that the equipment was from a Chinese manufacturer

“宝山”baoshan, the site of China's largest steel mill in Shanghai

Assuming they were related to the current project , the Chinese company in question would merely be acting as a supplier , if at all. There's absolutely no evidence either written or photographs or videos suggesting they commissioned the blast furnace last month.

Both you & the Chinese sources you're linking here don't provide evidence that the project the Chinese company claims to have executed is for the blast furnace commissioned last month nor does the client Tata Steel make any mention of a Chinese company or consultancy being involved in the current project.

What the Chinese company is doing is recycling old news for reasons it knows best & you're blindly linking such articles here without verifying facts for your propaganda purposes here.

Please do take note of the entire exchange . @SKC ; @Suryavanshi