- Joined

- Jun 30, 2024

- Messages

- 2,908

- Likes

- 25,294

PCB manufacture is def good news.

Current (((value addition))) is just soldering imported chips to imported PCB using imported machines( or maybe workers )

not true. PCBs are the only thing being manufactured currently in all these assembly sweatshops, using imported machines. The actual materials of the PCBs are of course imported, but the soldering, etching etc all takes place. What india actually needs is dozens of large scale PCB companies making them at scale across the country. Even today it is cheaper and faster to fabricate your custom PCBs from China (jlcpcb etc) than local companies.

View: https://x.com/TiwariRishik/status/1838879794563592389

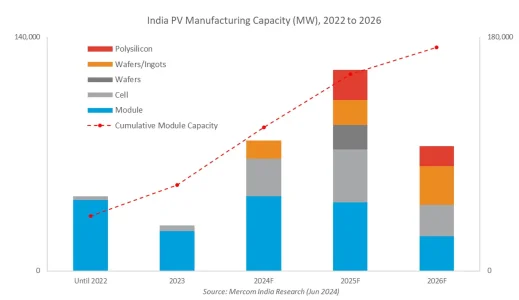

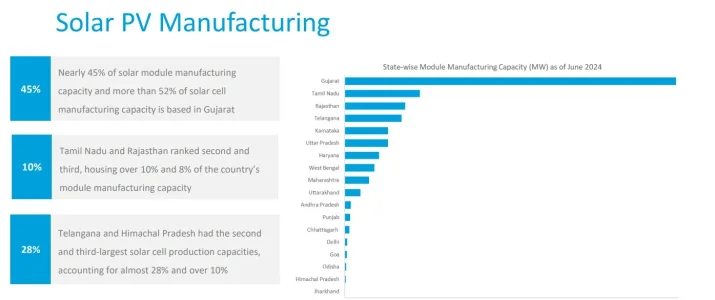

The gujarat stats are mind boggling, good for them.Solar industry in India. By 2026, Indian companies will have a capacity of 172GW of modules, 80GW of cell and ~50GW of wafer/ingot and ~30GW of polysilicon, from the current capacity of 77GW, 7.6GW, 2GW and 0GW respectively. Brutal module overcapacity incoming.

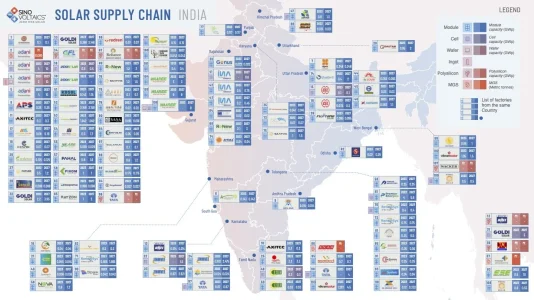

These are all the announced ones where construction is already underway or approved by the company. New ones are being announced every other day. 1 area where india is completely absent is the machinery to make cells,modules etc. Fully imported from cheen

From @bakofbakchod

View attachment 11737View attachment 11738View attachment 11739

Solar industry in India. By 2026, Indian companies will have a capacity of 172GW of modules, 80GW of cell and ~50GW of wafer/ingot and ~30GW of polysilicon, from the current capacity of 77GW, 7.6GW, 2GW and 0GW respectively. Brutal module overcapacity incoming.

These are all the announced ones where construction is already underway or approved by the company. New ones are being announced every other day. 1 area where india is completely absent is the machinery to make cells,modules etc. Fully imported from cheen

From @bakofbakchod

View attachment 11737View attachment 11738View attachment 11739

Time to introduce PLI for mfg those machines in the solar industry sector now. That's how you close the loop & build a backward integrated end to end supply chain. Replicate it in every other industrial sector then to the extent possible. The template of China's before you. All you've to do is emulate itCan't have the whole supply chain at once unless it's some Govt project backed by big $$$, manufacturing solar panels from ingot/wafer level here is still progress as compared to PHOOL IMPORT SAAR from cheen

It would be great to get a case study of what allows Noida to be an excellent manufacturing location for electronic.

Does it look that bad? The area on the right is probably construction site, the actual area looks pretty good just need some more greenery.Why do Indian factories looks dirty & unorganised, unkempt both inside and outside?

Manufacturing is art in itself ,premises should be good to look at.

It would be great to get a case study of what allows Noida to be an excellent manufacturing location for electronic.

Like what factors? Land, water, labour, skilled labour etc.

Why do Indian factories looks dirty & unorganised, unkempt both inside and outside?

Manufacturing is art in itself ,premises should be good to look at.

MoreSolar industry in India. By 2026, Indian companies will have a capacity of 172GW of modules, 80GW of cell and ~50GW of wafer/ingot and ~30GW of polysilicon, from the current capacity of 77GW, 7.6GW, 2GW and 0GW respectively. Brutal module overcapacity incoming.

These are all the announced ones where construction is already underway or approved by the company. New ones are being announced every other day. 1 area where india is completely absent is the machinery to make cells,modules etc. Fully imported from cheen

From @bakofbakchod

View attachment 11737View attachment 11738View attachment 11739