You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Latin America Technology and Industry

- Thread starter E-195

- Start date

More options

Who Replied?- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

In this sense, the technological legacy of Lanix, as a Mexican company, goes beyond personal computing, as today it has a portfolio made up of laptops, tablets, smartphones and servers.

Likewise, it has other product lines such as smart air conditioning and vacuum robots, which, following market requirements, can be controlled from the Lanix Smarthome app, or, through voice commands, from the Google Assistant. or Alexa, thus forming products from its IoT line, which continues to grow

Lanix: la mexicana que no se detiene y sigue su evolución #HechoEnMéxico

Lanix: la mexicana que no se detiene y sigue su evolución fabricando mucho más que cómputo gracias a su constante innovación.

reseller.com.mx

reseller.com.mx

Nosotros - LANIX

In its history, Lanix has a portfolio of more than 30 mobile phones, through which it has currently managed to have 3.4% of the Mexican market, a factor that has allowed it to generate global alliances with América Móvil and MediaTek.

Estas son las marcas mexicanas de smartphones que tal vez no conocías

Nos dimos a la tarea de buscar las marcas mexicanas de smartphones y mostrar que en México se genera tecnología de punta.

Se renueva estrategia de negocio para canales de Lanix con más incentivos

Una de las prioridades de Lanix es su estrategia de negocio para canales de distribución, por ello prepara una plataforma de incentivos.

reseller.com.mx

reseller.com.mx

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

DINA is a Mexican bus and truck manufacturer based in Ciudad Sahagún, Hidalgo, Mexico. It was created by the federal government of Mexico in 1951

dina.com.mx

dina.com.mx

Agrale, previously called AGRISA, is a Brazilian vehicle manufacturer. Established in 1962, it is based in Caxias do Sul in the state of Rio Grande do Sul.

Agrale forklift by the daughter company Lintec

www.agrale.com.br

www.agrale.com.br

Autopartes y Componentes S.A. de C.V (AYCO)

With a 37-year-old manager

It is a Mexican company leader in the manufacture of bodies for urban, interurban and foreign buses, its headquarters are located in Huehuetoca, State of Mexico.

www.ayco.com.mx

www.ayco.com.mx

Eletra was officially opened on August 22, 2000 It is a Brazilian company that began operating in one of the garages of Auto Viação ABC, a public transport company founded in 1956 by José Fernando Medina Braga and Maria Myrtis Setti Braga, on Avenida Dr. José Fornari, in São Bernardo do Campo. It is a Brazilian technology company that knows its market and has its sights set on the 21st century.

www.eletrabus.com.br

www.eletrabus.com.br

Vekstar-Moldex is a Mexican company developing electric cars

Meet the Mexican engineers behind the development of our Vekstar electric delivery vehicles, assembled at Moldex. With their dedication and talent they have been a key piece on the path towards sustainable mobility and so that today we have the largest electric fleet in Latin America.

Quiénes somos - DINA

En DINA diseñamos y fabricamos los mejores autobuses de pasajeros y camiones de carga creados para la movilidad y proyectos demandantes del mercado.

Agrale, previously called AGRISA, is a Brazilian vehicle manufacturer. Established in 1962, it is based in Caxias do Sul in the state of Rio Grande do Sul.

Agrale forklift by the daughter company Lintec

Agrale - Tratores, Caminhões, Chassis, Utilitários e Motores

Com 50 anos de tradição e solidez, é a única empresa de capital e controle 100% nacional que atua na produção de tratores, caminhões, chassis, utilitátios e motores.

Autopartes y Componentes S.A. de C.V (AYCO)

With a 37-year-old manager

It is a Mexican company leader in the manufacture of bodies for urban, interurban and foreign buses, its headquarters are located in Huehuetoca, State of Mexico.

AYCO – …Moviendo a México

www.ayco.com.mx

www.ayco.com.mx

Eletra was officially opened on August 22, 2000 It is a Brazilian company that began operating in one of the garages of Auto Viação ABC, a public transport company founded in 1956 by José Fernando Medina Braga and Maria Myrtis Setti Braga, on Avenida Dr. José Fornari, in São Bernardo do Campo. It is a Brazilian technology company that knows its market and has its sights set on the 21st century.

ônibus elétrico – Eletra

Vekstar-Moldex is a Mexican company developing electric cars

Meet the Mexican engineers behind the development of our Vekstar electric delivery vehicles, assembled at Moldex. With their dedication and talent they have been a key piece on the path towards sustainable mobility and so that today we have the largest electric fleet in Latin America.

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

A radar developed 100% in Campinas, and launched this Friday (10) will reinforce Brazil's anti-aircraft defense. The Saber M200 Vigilante, developed by Embraer in partnership with the Army.

On June 20, the SABER M200 Vigilante radar, developed by the Army Technological Center (CTEx) and produced by Embraer Defense & Security, was boarded for the first time on a Brazilian Air Force KC-390 aircraft bound for Parintins, in the state of Amazonas.

This complex operation involved the Brazilian Army, the Brazilian Air Force, Embraer, the City of Parintins and the administration of the Viracopos and Parintins airports. The objective was to use the SABER M200 radar to monitor and control the airspace at Júlio Belém Airport, in Parintins. With the ability to detect threats from up to 15 km in altitude, the radar is capable of identifying and tracking civil and military aircraft. It will remain in operation in the region until July 7th.

The SABER M200 is a medium height multi-mission air defense radar with three-dimensional capability. Using advanced electronic scanning technology, the radar can detect and track aircraft simultaneously. In addition, it has the ability to guide missiles, carry out surveillance, meteorology and approach missions within a radius of 45 kilometers.

An important highlight is that the SABER M200 is the first fixed panel radar available on the world market, allowing it to be installed in a 20-foot container (6,096 meters), providing greater ease of transport and mobility. With diverse applications, radar can be used in surveillance and early warning activities in Anti-Aircraft Artillery Batteries and Groups, air traffic control and border surveillance.

The successful operation of the SABER M200 in Parintins represents an important milestone in the country's security and defense. With its advanced technology and multifunctional capabilities, this radar promises to play a fundamental role in the protection and aerial surveillance of Brazil.

Watch this video to learn in detail about the SABER M200 Vigilante radar and understand how this technology is contributing to strengthening national security and the defense of Brazilian airspace.

View: https://www.youtube.com/watch?v=AH05d3tQm1k

View: https://www.youtube.com/watch?v=CJ-Lx_uWYyE

On June 20, the SABER M200 Vigilante radar, developed by the Army Technological Center (CTEx) and produced by Embraer Defense & Security, was boarded for the first time on a Brazilian Air Force KC-390 aircraft bound for Parintins, in the state of Amazonas.

This complex operation involved the Brazilian Army, the Brazilian Air Force, Embraer, the City of Parintins and the administration of the Viracopos and Parintins airports. The objective was to use the SABER M200 radar to monitor and control the airspace at Júlio Belém Airport, in Parintins. With the ability to detect threats from up to 15 km in altitude, the radar is capable of identifying and tracking civil and military aircraft. It will remain in operation in the region until July 7th.

The SABER M200 is a medium height multi-mission air defense radar with three-dimensional capability. Using advanced electronic scanning technology, the radar can detect and track aircraft simultaneously. In addition, it has the ability to guide missiles, carry out surveillance, meteorology and approach missions within a radius of 45 kilometers.

An important highlight is that the SABER M200 is the first fixed panel radar available on the world market, allowing it to be installed in a 20-foot container (6,096 meters), providing greater ease of transport and mobility. With diverse applications, radar can be used in surveillance and early warning activities in Anti-Aircraft Artillery Batteries and Groups, air traffic control and border surveillance.

The successful operation of the SABER M200 in Parintins represents an important milestone in the country's security and defense. With its advanced technology and multifunctional capabilities, this radar promises to play a fundamental role in the protection and aerial surveillance of Brazil.

Watch this video to learn in detail about the SABER M200 Vigilante radar and understand how this technology is contributing to strengthening national security and the defense of Brazilian airspace.

View: https://www.youtube.com/watch?v=AH05d3tQm1k

View: https://www.youtube.com/watch?v=CJ-Lx_uWYyE

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

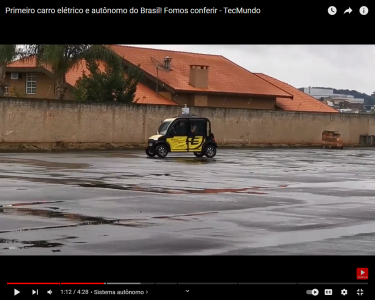

Hitech Electric launched Brazil's first electric and autonomous car, which can be "controlled" remotely via cell phone. Named e.coTech 4 Autonomous, the vehicle was developed in partnership with Positivo and the startup Lume Robotics, born in the High Performance Computing Laboratory of the Federal University of Espírito do Santo (UFES). TecMundo went to check out this news!

Eolo, a 100% Colombian electric car

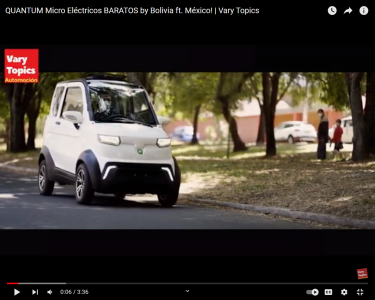

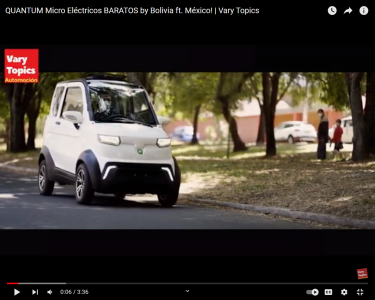

The Bolivian start-up Quantum surprises with an electric microcar

The Quantum company manufactures a small electric car model. Its managers trust that the country's lithium reserves will allow them to stop importing electric batteries in the medium term.

THIS IS THE FACTORY OF A MEXICAN SUPERCAR

How is the Mexican Supercar Made? - VUHL

Gurgel Itaipu was the first Brazilian national electric car, but there were problems due to existing problems below.

The Itaipu E150 weighed 460 kg, 320 kg being just 3.2 kW batteries that deliver or equivalent to 4.2 hp. Weight, autonomy and recharge foram barrels for the little one

Iglesias the first totally Argentine car

Manuel Iglesias' car began to take shape in 1903. The construction of the pieces was carried out by hand using a pedal lathe, homemade tools of his own making, and the back of the house on Colón Street, in Campana, as a workshop.

It was a simple, utilitarian vehicle, with capacity for two people. It was built with a rectangular chassis of stringers and crossmembers with a rigid front axle, which incorporated steering, and a rear axle with differential.

autohistoria.com.ar

Thanks to the efforts of Governor José Rosas Aispuro Torres, 52 million dollars will be invested and hundreds of jobs will be generated with the companies Siete Leguas Automotive and Tecopress

autohistoria.com.ar

Thanks to the efforts of Governor José Rosas Aispuro Torres, 52 million dollars will be invested and hundreds of jobs will be generated with the companies Siete Leguas Automotive and Tecopress

Siete Leguas Automotive: production of world-class auto parts

Four years ago, a production plant for aluminum automotive components was created in Gómez Palacio, Durango. What started only with gearbox machining is now a comprehensive manufacturing process for aluminum injection pressure casting and auto parts machining to supply the most important OEMs.

The initiative began with three CNC machines to machine aluminum parts that they bought in the local market. But the SL Automotive project was more ambitious and a joint venture was signed with the Italian company Tecopress to produce its own aluminum components. At the end of 2020, they installed the first two fully automated aluminum injection cells, and in 2021 they began to cast the first parts, which they subsequently machined to deliver directly to customers' assembly lines.

Configuration of machining centers

The machining area of Siete Leguas Automotive has 26 Makino machines, organized in production cells, some of them dedicated to a single product and others of them multi-product. During my visit they were installing two new Makino machining centers and in the first quarter of 2022 they will receive four more. Some machines are model a61 NX Model B and others are the same model with the Y axis extended.

Siete Leguas Automotive has 26 Makino machines.

Siete Leguas Automotive has 26 Makino machines, organized in production cells, where they machine parts simultaneously on two sides, in cube-type clamping systems they made themselves.

These machines have offered them several advantages for the machining of their aluminum parts: “The first include precision, repeatability and robustness. They have the broken tool system, which does not consume cycle time, since it is done when the tool comes out using vision techniques. The spindle accelerations are quite good, in the warm ups or warm-ups of the machine there is a minimum variation and the precision does not fail, we have them very well equipped and they have not caused maintenance problems," says Jesús Manchado, engineering director of Siete Leguas Automotive.

All Makino machines organized by cells have four axes. “They are very versatile, they are very flexible horizontal machines and, since all the machines are the same, in the event that one breaks, we can change the missing component to the other. With 26 identical CNCs we have a lot of versatility in terms of maintenance.”

Performance in machining production is measured with the data that operators enter into PCs adapted to the machining lines and that reach a database where reports are automatically generated.

“Each machine has a mini-PC in which the operator writes down the data with his losses, with the amount and type of scrap, how many have been approved, how many have not, and in the end everything is added up on the server and we get a report. ”.

Cube-type 'pallets' as a solution

The machining time of each component depends on the part. “In the case of the gearbox or gear housing that we machine, one of its components takes four minutes, the other six and the complete assembly takes nine minutes,” says Jesús Manchado.

Each component is taken to a machine for leak, differential and pressure testing.

Each component is taken to a machine for leak, differential and pressure testing.

The configuration of the centers is for multi-product. This means a bucket-type clamping system on both pallets. “We call this fastening system a cube because it has four sides. In each of them we can put different tooling or fixtures and we configure them so that with the annual demand we load this machine above 85%. Thus, the only reference change will be the program, which does not take us time and we do not have to dismantle and load fixtures, because we do the annual configuration and leave it according to our demand,” explains Jesús Manchado.

In the end, the idea is to reduce the reference change time, one of the biggest losses that a machining workshop has, speaking of OEE. OEE is the way to measure manufacturing productivity that identifies the percentage of manufacturing time that is actually productive. An OEE score of 100% means that only good parts are being manufactured, as quickly as possible, without downtime.

Siete Leguas Automotive's machining system is cell-type work. For example, for one of their 2-cylinder crankcases, the first three CNCs make the left part and the right part separately. Each of these three machines does the same operation and the last one already makes the assembled piece, cell type. On the fourth machine they already have the piece assembled and machine it; then it goes through the leaking and washing process. “We try to ensure that there are no pieces in between. The piece of raw material enters at the beginning of the cell and when it is finished it comes out assembled,” says Manchado.

For the assembly processes they have semi-automated stations, but there are others that have robots, such as the torque machine, where the two counterparts are assembled and the screws are placed. This machine makes the tightening torque, always with the same sequence for each screw

www.mms-mexico.com

www.mms-mexico.com

View: https://www.youtube.com/watch?v=QaFdEqAZIQs

View: https://www.youtube.com/watch?v=j8X1Dlmuo04

View: https://www.youtube.com/watch?v=SXnUdY3sR54

View: https://www.youtube.com/watch?v=rIWXd0Ykxdk

Eolo, a 100% Colombian electric car

The Bolivian start-up Quantum surprises with an electric microcar

The Quantum company manufactures a small electric car model. Its managers trust that the country's lithium reserves will allow them to stop importing electric batteries in the medium term.

THIS IS THE FACTORY OF A MEXICAN SUPERCAR

How is the Mexican Supercar Made? - VUHL

Gurgel Itaipu was the first Brazilian national electric car, but there were problems due to existing problems below.

The Itaipu E150 weighed 460 kg, 320 kg being just 3.2 kW batteries that deliver or equivalent to 4.2 hp. Weight, autonomy and recharge foram barrels for the little one

Iglesias the first totally Argentine car

Manuel Iglesias' car began to take shape in 1903. The construction of the pieces was carried out by hand using a pedal lathe, homemade tools of his own making, and the back of the house on Colón Street, in Campana, as a workshop.

It was a simple, utilitarian vehicle, with capacity for two people. It was built with a rectangular chassis of stringers and crossmembers with a rigid front axle, which incorporated steering, and a rear axle with differential.

Iglesias el primer auto totalmente argentino - Fabricado entre 1903 y 1907

Iglesias el primer auto totalmente argentino. Con excepción del magneto y la bujía, todas las piezas fueron fabricadas por Don Manuel.

autohistoria.com.ar

autohistoria.com.ar

Siete Leguas Automotive: production of world-class auto parts

Four years ago, a production plant for aluminum automotive components was created in Gómez Palacio, Durango. What started only with gearbox machining is now a comprehensive manufacturing process for aluminum injection pressure casting and auto parts machining to supply the most important OEMs.

The initiative began with three CNC machines to machine aluminum parts that they bought in the local market. But the SL Automotive project was more ambitious and a joint venture was signed with the Italian company Tecopress to produce its own aluminum components. At the end of 2020, they installed the first two fully automated aluminum injection cells, and in 2021 they began to cast the first parts, which they subsequently machined to deliver directly to customers' assembly lines.

Configuration of machining centers

The machining area of Siete Leguas Automotive has 26 Makino machines, organized in production cells, some of them dedicated to a single product and others of them multi-product. During my visit they were installing two new Makino machining centers and in the first quarter of 2022 they will receive four more. Some machines are model a61 NX Model B and others are the same model with the Y axis extended.

Siete Leguas Automotive has 26 Makino machines.

Siete Leguas Automotive has 26 Makino machines, organized in production cells, where they machine parts simultaneously on two sides, in cube-type clamping systems they made themselves.

These machines have offered them several advantages for the machining of their aluminum parts: “The first include precision, repeatability and robustness. They have the broken tool system, which does not consume cycle time, since it is done when the tool comes out using vision techniques. The spindle accelerations are quite good, in the warm ups or warm-ups of the machine there is a minimum variation and the precision does not fail, we have them very well equipped and they have not caused maintenance problems," says Jesús Manchado, engineering director of Siete Leguas Automotive.

All Makino machines organized by cells have four axes. “They are very versatile, they are very flexible horizontal machines and, since all the machines are the same, in the event that one breaks, we can change the missing component to the other. With 26 identical CNCs we have a lot of versatility in terms of maintenance.”

Performance in machining production is measured with the data that operators enter into PCs adapted to the machining lines and that reach a database where reports are automatically generated.

“Each machine has a mini-PC in which the operator writes down the data with his losses, with the amount and type of scrap, how many have been approved, how many have not, and in the end everything is added up on the server and we get a report. ”.

Cube-type 'pallets' as a solution

The machining time of each component depends on the part. “In the case of the gearbox or gear housing that we machine, one of its components takes four minutes, the other six and the complete assembly takes nine minutes,” says Jesús Manchado.

Each component is taken to a machine for leak, differential and pressure testing.

Each component is taken to a machine for leak, differential and pressure testing.

The configuration of the centers is for multi-product. This means a bucket-type clamping system on both pallets. “We call this fastening system a cube because it has four sides. In each of them we can put different tooling or fixtures and we configure them so that with the annual demand we load this machine above 85%. Thus, the only reference change will be the program, which does not take us time and we do not have to dismantle and load fixtures, because we do the annual configuration and leave it according to our demand,” explains Jesús Manchado.

In the end, the idea is to reduce the reference change time, one of the biggest losses that a machining workshop has, speaking of OEE. OEE is the way to measure manufacturing productivity that identifies the percentage of manufacturing time that is actually productive. An OEE score of 100% means that only good parts are being manufactured, as quickly as possible, without downtime.

Siete Leguas Automotive's machining system is cell-type work. For example, for one of their 2-cylinder crankcases, the first three CNCs make the left part and the right part separately. Each of these three machines does the same operation and the last one already makes the assembled piece, cell type. On the fourth machine they already have the piece assembled and machine it; then it goes through the leaking and washing process. “We try to ensure that there are no pieces in between. The piece of raw material enters at the beginning of the cell and when it is finished it comes out assembled,” says Manchado.

For the assembly processes they have semi-automated stations, but there are others that have robots, such as the torque machine, where the two counterparts are assembled and the screws are placed. This machine makes the tightening torque, always with the same sequence for each screw

Siete Leguas Automotive: producción de autopartes de clase mundial

Lo que empezó solo con mecanizado para cajas de engranaje, ahora es un proceso de manufactura integral de fundición de presión de inyección de aluminio y mecanizado de autopartes.

View: https://www.youtube.com/watch?v=QaFdEqAZIQs

View: https://www.youtube.com/watch?v=j8X1Dlmuo04

View: https://www.youtube.com/watch?v=SXnUdY3sR54

View: https://www.youtube.com/watch?v=rIWXd0Ykxdk

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

Mirage X-One Portable Air Conditioner from the Mexian brand Mirage

The MIRAGE project began in 1984 to provide excellent services and the best air conditioning products, establishing itself as a company in 1998. In 1999, the corporate office was established in Ciudad Obregón, Sonora, Mexico. In 2000, an operations center was established in Mexicali and invested heavily in technology to solve the growing need in communications, information management, administration and logistics.

For 2002, distribution centers were added in Hermosillo, Culiacán, Monterrey and Veracruz, and for 2003 Los Cabos, Mazatlán, Reynosa, Guadalajara and Cancún.

MIRAGE was defined as a solid company by 2004 and by earning a place alongside powerful transnational companies.

In 2006 Mirage was a pioneer in its industry, certifying its processes under the ISO 9001/2000 standard; thus implementing a quality system with worldwide recognition.

The important step in 2007 was the expansion of its marketing channels, introducing its products to the most important Department and Self-Service stores, such as Wal-Mart, Elektra, Coppel, Liverpool, among others.

mirage.mx

Welcome to this video in which I will show you what's new from DINA for 2024! The renowned Mexican brand has launched an interesting range of models to continue making history in the world of transportation. From the versatile Picker 8 designed for urban passenger transportation, to the efficient Runner Águila perfect for transporting personnel, and DINA's return to the cargo segment with its vocational vehicles. In this video, we will break down each model knowing its notable features. Come with me to see what DINA has in store for you in 2024!

mirage.mx

Welcome to this video in which I will show you what's new from DINA for 2024! The renowned Mexican brand has launched an interesting range of models to continue making history in the world of transportation. From the versatile Picker 8 designed for urban passenger transportation, to the efficient Runner Águila perfect for transporting personnel, and DINA's return to the cargo segment with its vocational vehicles. In this video, we will break down each model knowing its notable features. Come with me to see what DINA has in store for you in 2024!

MASTRETTA. ELECTRIC BIKES a company from MEXICO CITY. BIKE TAXIS CENTER MEXICO CITY.

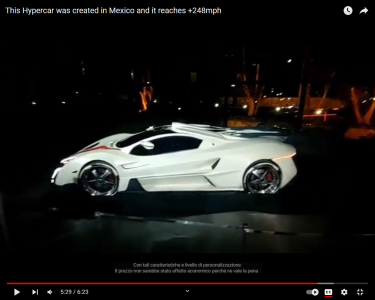

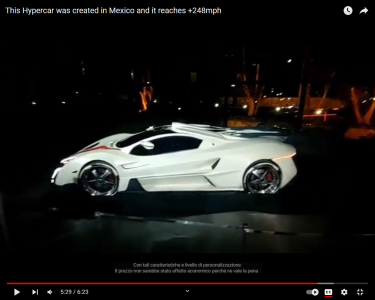

This Hypercar was created in Mexico and it reaches +248mph the Inferno

You are not familiar with Voltz, a Brazilian brand with a factory in Manaus with the capacity to produce 200 thousand motorcycles per year. Here the brand sells two models in Brazil, the EV1 Sport scooter and the EVS urban motorcycle

On the motorcycle, pay attention to the futuristic design, TFT digital panel and all LED lighting: position light, indicators, headlights, rear lamp and brake light.

The Voltz electric motor is in the rear wheel and has 3,000 Watts of power, which is equivalent to 4 horsepower. The temperature and torque are equal to the ECO, Standard and Turbo driving modes, which can be selected via the direct switch.

The Voltz EVS is small, even more so when compared to other street motorcycle models, and weighs just 147 kilos, even with two batteries.

Will it be the same as what you need when buying your first electric motorcycle? Then just click play, share this video with your friends and leave your comment here below saying what's new!

Bimex e-Bike from Mexico

bimex.mx

bimex.mx

View: https://www.youtube.com/watch?v=F76U5nINWfQ&t=96s

View: https://www.youtube.com/watch?v=MUYjSq4i0Gk

View: https://www.youtube.com/watch?v=Ry1eEDg7n_g

View: https://www.youtube.com/watch?v=OD6CjewgEsA

The MIRAGE project began in 1984 to provide excellent services and the best air conditioning products, establishing itself as a company in 1998. In 1999, the corporate office was established in Ciudad Obregón, Sonora, Mexico. In 2000, an operations center was established in Mexicali and invested heavily in technology to solve the growing need in communications, information management, administration and logistics.

For 2002, distribution centers were added in Hermosillo, Culiacán, Monterrey and Veracruz, and for 2003 Los Cabos, Mazatlán, Reynosa, Guadalajara and Cancún.

MIRAGE was defined as a solid company by 2004 and by earning a place alongside powerful transnational companies.

In 2006 Mirage was a pioneer in its industry, certifying its processes under the ISO 9001/2000 standard; thus implementing a quality system with worldwide recognition.

The important step in 2007 was the expansion of its marketing channels, introducing its products to the most important Department and Self-Service stores, such as Wal-Mart, Elektra, Coppel, Liverpool, among others.

Historia de Mirage

MASTRETTA. ELECTRIC BIKES a company from MEXICO CITY. BIKE TAXIS CENTER MEXICO CITY.

This Hypercar was created in Mexico and it reaches +248mph the Inferno

You are not familiar with Voltz, a Brazilian brand with a factory in Manaus with the capacity to produce 200 thousand motorcycles per year. Here the brand sells two models in Brazil, the EV1 Sport scooter and the EVS urban motorcycle

On the motorcycle, pay attention to the futuristic design, TFT digital panel and all LED lighting: position light, indicators, headlights, rear lamp and brake light.

The Voltz electric motor is in the rear wheel and has 3,000 Watts of power, which is equivalent to 4 horsepower. The temperature and torque are equal to the ECO, Standard and Turbo driving modes, which can be selected via the direct switch.

The Voltz EVS is small, even more so when compared to other street motorcycle models, and weighs just 147 kilos, even with two batteries.

Will it be the same as what you need when buying your first electric motorcycle? Then just click play, share this video with your friends and leave your comment here below saying what's new!

Bimex e-Bike from Mexico

Bimex – La bici diferente.

Nuestro Catálogo Cuidado al medio ambiente Manufactura amable con el planeta. Viaja rápido y seguro Nuestras bicicletas cuentan con la mas alta tecnología en rendimiento. Durabilidad y calidad Porque te mereces lo mejor. Encuentra tu

View: https://www.youtube.com/watch?v=F76U5nINWfQ&t=96s

View: https://www.youtube.com/watch?v=MUYjSq4i0Gk

View: https://www.youtube.com/watch?v=Ry1eEDg7n_g

View: https://www.youtube.com/watch?v=OD6CjewgEsA

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

Ferdof is a Brazilian company founded in 2017, in Batatais (SP), by businessmen Filipe and Fernando. The dream of both, engineers by training, was to manufacture any type of machine, from simple equipment to the most complex, including CNC machines. Therefore, they created the slogan “You Think, We Make” for the new business, showing that, first and foremost, the company had the ambition to meet all the needs of its customers.

“The company had a highly qualified team, made up of engineers and technicians specialized in different areas”, says Filipe A. Silva, current CEO and co-founder of Ferdof. Over time, he and Fernando realized that the national market needed machines manufactured by people who knew the operation. “It was then that the company decided to specialize in CNC machines, in order to offer customers high-quality equipment and a highly qualified team,” he says.

View: https://www.youtube.com/watch?v=2gk4jmxaL8A

emobile.com.br

First Mexican company to develop a commercially successful CNC control

emobile.com.br

First Mexican company to develop a commercially successful CNC control

VIWA manufactures in Mexico and exports machinery to more than 10 countries

First Mexican company to build a metal 3D printer

View: https://www.youtube.com/watch?v=Sfd6XwACFec

viwacnc.com

viwacnc.com

“The company had a highly qualified team, made up of engineers and technicians specialized in different areas”, says Filipe A. Silva, current CEO and co-founder of Ferdof. Over time, he and Fernando realized that the national market needed machines manufactured by people who knew the operation. “It was then that the company decided to specialize in CNC machines, in order to offer customers high-quality equipment and a highly qualified team,” he says.

View: https://www.youtube.com/watch?v=2gk4jmxaL8A

Ferdof oferta máquinas CNC para indústria - eMóbile

Ferdof oferta máquinas CNC para cortes, furação e usinagem na indústria moveleira, tendo enorme crescimento nos últimos anos

emobile.com.br

emobile.com.br

VIWA manufactures in Mexico and exports machinery to more than 10 countries

First Mexican company to build a metal 3D printer

View: https://www.youtube.com/watch?v=Sfd6XwACFec

Nosotros - Viwa CNC: Tornos, Fresadoras, Centros de Maquinado CNC

Centros de Maquinado CNC, verticales, tipo puente, Fresadoras CNC, Tornos CNC, Taladradoras, accesorios y herramientas

viwacnc.com

viwacnc.com

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

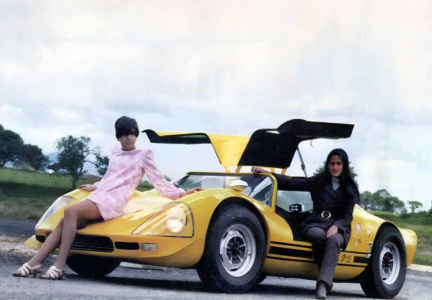

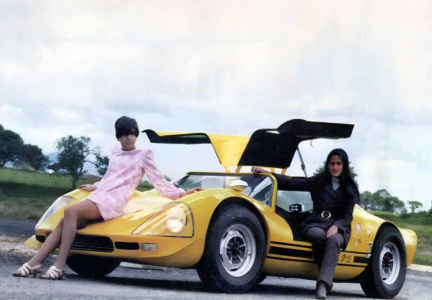

At the end of the sixties, when national car production was emerging, the German engineer Dieter Herber, who lived in Colombia, undertook the creation of the Cacique Tayrona. His motivation was to create a national sports car for the street and competitions, given the difficulty of importing them.

.

Three friends financed him, one of them Dr. Ignacio Berraquer, son of the founder of the clinic that bears his last name in Bogotá and in whose basement the vehicle in question was assembled. The body, made of fiberglass and inspired by the Ferrari P4, was created and produced in these facilities... from where it came disassembled to be finished in a warehouse in Chía.

The car was mounted on a tubular chassis, and inside, there was a 1.5-liter V4 central engine from the Ford Taunus. According to Herber, cited by Motor, between five and six units of the Cacique Tayrona were produced at prices lower than those of a new Renault 4. Two units survive.

“The Colombian Economic Car” was a project created by a team of independent designers, Industrial Design students from the National University, led by the French industrial designer Dominique Billioté. This last piece of information sheds light on what it was: a Creole and expanded version of the Renault 4.

.

The project was presented in March 1987. It included an urban version, a hatchback, a family car, a pick-up and a van. Renault-Sofasa provided engines and platforms to the project. A high degree of integration of national parts was expected, which would result in a price 30% lower than the cheapest car at the time, which was... yes, the same Renault 4.

.

The equipment would include rubber or fiber mats, luxury seats in cordovan or cloth, heating, radio pre-installation, glove compartment, headrest, two rear-view mirrors and two-tone paint. Renault-Sofasa would enter as an investment partner, but things did not happen. To date, it is not known why.

Steed Cargo 1.6 (1992)

The Corcel vehicle plant was a venture by Valle del Cauca industrialist Raúl Grajales, which was unveiled in September 1992 and whose center was the Corcel Cargo 1.6, a very particular cargo vehicle.

.

Designed by Luis Alfonso Calderón, it was a mix of many things: the cabin of a Mazda B2000, the front axle of a Chevette and the rear axle and suspension of a VW Beetle 1600. From the latter, the engine and box also came. The front was flat, with the lights embedded in the body.

.

It would compete with the motocars of the time, but according to Motor, the media that reported it at the time, the thing did not go beyond a few prototypes.

MUB 1Q (2020)

It is also an electric cargo quadricycle, but created by the company Mubility based in Sabaneta, Antioquia. Its leaders are David Sierra, Pablo Gaviria and Mauricio Toro, specialists in developing products based on high precision and high engineering technologies.

.

This vehicle, already approved by the Ministry of Transport and of which 15 units have been produced, has a load capacity of around 700 kg, open cabin (without doors), and double or single cabin versions. In addition, it pulls up to a ton. It is recharged at 110 or 220V outlets for four hours, obtaining an estimated range of 50 kilometers.

.

Its creators define it as a vehicle “designed for use and abuse”, adaptable for different uses such as tents, refrigerators and benches, among others. It incorporates IoT sensors that transmit data on the use and operation of each vehicle, route maps, maintenance, routes and other data.

Veclom from VEC mexican EV designer

What is the bus production line like? Volare is the Brazilian leader in the manufacture of minibuses, and Liam Mattera went to the factory in São Mateus-ES, to see the assembly line that has already manufactured more than 7 thousand vehicles, with the aim of revealing how a bus is created , both executive and urban models.

Furthermore, you will understand all the differences in Volare's minibus models, in addition to seeing up close all the highlights of the urban Volare Fly 10 model.

Since the beginning of its history, Volare has always focused on innovation, remembering that it is a company belonging to the Marcopolo Group. It has been on the road for more than 24 years, driving the future of mobility and making it easier for people to reach their destinations using minibuses.

With highly modern industrial facilities and production processes, the São Mateus factory in Espírito Santo adopts cutting-edge technology systems, with welding and painting robotization, process optimization, automation, functional layout and laser cutting in tubes and sheets.

The entire process of building a Volare begins with assembling the structure with exclusive templates and then coupling it to the chassis. The bus then receives the initial components for the sides and roof and is then taken to the painting booth.

Then the body goes into a new line, to place all the items and interior finishes. Side panels, roof, upholstery, floor, glass, instrument panel, seats, package holders, as well as audio and video equipment.

Finally, the vehicle receives calls, completing the process involving mechanical and electronic systems.

The vehicle then undergoes a visual inspection and other important tests for the proper functioning of the vehicle where assembly is completed. Afterwards, several tightness tests are carried out on Volare's test tracks at the São Mateus factory itself.

The brand's line of minibuses is considered the most complete on the market.

There are different vehicles, with configurations from 6 to 10 tons, produced according to the demands of each client, understanding their needs and developing ideal solutions for their businesses.

To serve each segment, the brand produces vehicles in Executive, Charter, Urban, School, Rural, 4x4, Off Road (or “off-road” vehicles) versions. All of this through four specific lines:

Fly Line — the brand's premium line includes the Fly 9 and 10 models. Models with differentiated design, ample internal space, quality and functionality.

Attack Line — has the Attack 8 and 9 models. With functionality, robustness and great performance. The brand's best-selling line.

Access Line — known for its rear engine and full air pneumatic suspension that offer comfort and accessibility.

Special units — Volare is also recognized for providing the market with special Volare Fire, CFC, ambulance, and mobile units products.

In the video about how a bus is created, you can also see in detail the differences of the urban Volare Fly 10 model. It has a Cummins ISF 3.8 engine with 162 hp and is in the 10 ton range.

The urban Volare Fly 10 offers great cost-benefit, excellent operational performance, low consumption and is the ideal minibus aimed at a large migration movement from large buses to micro buses, facilitating mobility in large urban centers.

And do you enjoy the world of buses, are you a fleet owner or are you fascinated by busology? This is certainly a video that will please and surprise anyone who wants to know more about Volare and Marcopolo buses and also our friends who are bus experts.

The candidate to be coordinator of the Defense committees of the Fourth Transformation, Claudia Sheinbaum, visited Kronos DTA, the space in Nuevo León where Monterrey native Eugenio Sada runs the electric car project.

From this technological center, where the components of electric cars are produced entirely, that is, the engines, bodies and batteries, Sheinbaum and Mauricio Cantú, one of its spokespersons at the national level, gave the start of manufacturing of the vehicles. 15 first prototypes, which have the potential to be mass produced.

Megaflux is a "spinoff" company (currently under registration in the US) of Potencia Industrial, it is the first company in Latin America and Mexico that designs and manufactures high efficiency electric traction motors, lithium battery packs, integrates these systems into a commercial vehicle chassis from external suppliers and offers these vehicles to clients who seek to reduce their operating costs, improve the quality of life of their operators, and limit the environmental impact

www.f6s.com

www.f6s.com

View: https://www.youtube.com/watch?v=qMtSA5sKZJ0

View: https://www.youtube.com/watch?v=mLCLIjzSgJA

.

Three friends financed him, one of them Dr. Ignacio Berraquer, son of the founder of the clinic that bears his last name in Bogotá and in whose basement the vehicle in question was assembled. The body, made of fiberglass and inspired by the Ferrari P4, was created and produced in these facilities... from where it came disassembled to be finished in a warehouse in Chía.

The car was mounted on a tubular chassis, and inside, there was a 1.5-liter V4 central engine from the Ford Taunus. According to Herber, cited by Motor, between five and six units of the Cacique Tayrona were produced at prices lower than those of a new Renault 4. Two units survive.

“The Colombian Economic Car” was a project created by a team of independent designers, Industrial Design students from the National University, led by the French industrial designer Dominique Billioté. This last piece of information sheds light on what it was: a Creole and expanded version of the Renault 4.

.

The project was presented in March 1987. It included an urban version, a hatchback, a family car, a pick-up and a van. Renault-Sofasa provided engines and platforms to the project. A high degree of integration of national parts was expected, which would result in a price 30% lower than the cheapest car at the time, which was... yes, the same Renault 4.

.

The equipment would include rubber or fiber mats, luxury seats in cordovan or cloth, heating, radio pre-installation, glove compartment, headrest, two rear-view mirrors and two-tone paint. Renault-Sofasa would enter as an investment partner, but things did not happen. To date, it is not known why.

Steed Cargo 1.6 (1992)

The Corcel vehicle plant was a venture by Valle del Cauca industrialist Raúl Grajales, which was unveiled in September 1992 and whose center was the Corcel Cargo 1.6, a very particular cargo vehicle.

.

Designed by Luis Alfonso Calderón, it was a mix of many things: the cabin of a Mazda B2000, the front axle of a Chevette and the rear axle and suspension of a VW Beetle 1600. From the latter, the engine and box also came. The front was flat, with the lights embedded in the body.

.

It would compete with the motocars of the time, but according to Motor, the media that reported it at the time, the thing did not go beyond a few prototypes.

MUB 1Q (2020)

It is also an electric cargo quadricycle, but created by the company Mubility based in Sabaneta, Antioquia. Its leaders are David Sierra, Pablo Gaviria and Mauricio Toro, specialists in developing products based on high precision and high engineering technologies.

.

This vehicle, already approved by the Ministry of Transport and of which 15 units have been produced, has a load capacity of around 700 kg, open cabin (without doors), and double or single cabin versions. In addition, it pulls up to a ton. It is recharged at 110 or 220V outlets for four hours, obtaining an estimated range of 50 kilometers.

.

Its creators define it as a vehicle “designed for use and abuse”, adaptable for different uses such as tents, refrigerators and benches, among others. It incorporates IoT sensors that transmit data on the use and operation of each vehicle, route maps, maintenance, routes and other data.

Los carros que se han creado en Colombia: creatividad, tenacidad y esfuerzo sobre ruedas

Más allá de la industria, se ha intentado crear marcas y modelos propios de carros en Colombia. Hoy 20 de julio, recordamos algunos de ellos.

www.elcarrocolombiano.com

Veclom from VEC mexican EV designer

What is the bus production line like? Volare is the Brazilian leader in the manufacture of minibuses, and Liam Mattera went to the factory in São Mateus-ES, to see the assembly line that has already manufactured more than 7 thousand vehicles, with the aim of revealing how a bus is created , both executive and urban models.

Furthermore, you will understand all the differences in Volare's minibus models, in addition to seeing up close all the highlights of the urban Volare Fly 10 model.

Since the beginning of its history, Volare has always focused on innovation, remembering that it is a company belonging to the Marcopolo Group. It has been on the road for more than 24 years, driving the future of mobility and making it easier for people to reach their destinations using minibuses.

With highly modern industrial facilities and production processes, the São Mateus factory in Espírito Santo adopts cutting-edge technology systems, with welding and painting robotization, process optimization, automation, functional layout and laser cutting in tubes and sheets.

The entire process of building a Volare begins with assembling the structure with exclusive templates and then coupling it to the chassis. The bus then receives the initial components for the sides and roof and is then taken to the painting booth.

Then the body goes into a new line, to place all the items and interior finishes. Side panels, roof, upholstery, floor, glass, instrument panel, seats, package holders, as well as audio and video equipment.

Finally, the vehicle receives calls, completing the process involving mechanical and electronic systems.

The vehicle then undergoes a visual inspection and other important tests for the proper functioning of the vehicle where assembly is completed. Afterwards, several tightness tests are carried out on Volare's test tracks at the São Mateus factory itself.

The brand's line of minibuses is considered the most complete on the market.

There are different vehicles, with configurations from 6 to 10 tons, produced according to the demands of each client, understanding their needs and developing ideal solutions for their businesses.

To serve each segment, the brand produces vehicles in Executive, Charter, Urban, School, Rural, 4x4, Off Road (or “off-road” vehicles) versions. All of this through four specific lines:

Fly Line — the brand's premium line includes the Fly 9 and 10 models. Models with differentiated design, ample internal space, quality and functionality.

Attack Line — has the Attack 8 and 9 models. With functionality, robustness and great performance. The brand's best-selling line.

Access Line — known for its rear engine and full air pneumatic suspension that offer comfort and accessibility.

Special units — Volare is also recognized for providing the market with special Volare Fire, CFC, ambulance, and mobile units products.

In the video about how a bus is created, you can also see in detail the differences of the urban Volare Fly 10 model. It has a Cummins ISF 3.8 engine with 162 hp and is in the 10 ton range.

The urban Volare Fly 10 offers great cost-benefit, excellent operational performance, low consumption and is the ideal minibus aimed at a large migration movement from large buses to micro buses, facilitating mobility in large urban centers.

And do you enjoy the world of buses, are you a fleet owner or are you fascinated by busology? This is certainly a video that will please and surprise anyone who wants to know more about Volare and Marcopolo buses and also our friends who are bus experts.

The candidate to be coordinator of the Defense committees of the Fourth Transformation, Claudia Sheinbaum, visited Kronos DTA, the space in Nuevo León where Monterrey native Eugenio Sada runs the electric car project.

From this technological center, where the components of electric cars are produced entirely, that is, the engines, bodies and batteries, Sheinbaum and Mauricio Cantú, one of its spokespersons at the national level, gave the start of manufacturing of the vehicles. 15 first prototypes, which have the potential to be mass produced.

¡Conoce esta propuesta de autos eléctricos mexicanos! Los estará desarrollando Kronos DTA

Mientras Tesla está por comenzar a construir una Gigafactory en el estado de Nuevo León, un regiomontano y su compañía Kronos DTA, esperan poder iniciar a producir sus autos eléctricos mexicanos asequibles.

www.deceroacien.com.mx

Megaflux is a "spinoff" company (currently under registration in the US) of Potencia Industrial, it is the first company in Latin America and Mexico that designs and manufactures high efficiency electric traction motors, lithium battery packs, integrates these systems into a commercial vehicle chassis from external suppliers and offers these vehicles to clients who seek to reduce their operating costs, improve the quality of life of their operators, and limit the environmental impact

Megaflux | F6S

Megaflux - Megaflux is a "spinoff" company (currently under registration in the US) of Potencia Industrial, it is the first company in Latin America that designs and manufactures high efficiency elect

View: https://www.youtube.com/watch?v=qMtSA5sKZJ0

View: https://www.youtube.com/watch?v=mLCLIjzSgJA

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

Agrale products. Agrale cooporation from Brazil produces several types of vehicles and products

View: https://www.youtube.com/watch?v=TE4EKX-KrPM

View: https://www.youtube.com/watch?v=TE4EKX-KrPM

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

Marcopolo S.A.

Founded on August 6, 1949, Marcopolo was born in Caxias do Sul – RS with the name of Nicola & Cia. Ltd. The company opened its doors with eight partners and fifteen employees and was one of the first Brazilian industries to manufacture bus bodies.

With more than 70 years of existence, it is a world reference in the manufacture of bus bodies and in the development of electromobility solutions in line with the most modern concepts of sustainability. With products running in over 120 countries across the five continents and aligned with the purpose of being a protagonist in mobility solutions, Marcopolo stands out for its broad portfolio of products developed with high technology to meet the needs of its customers.

Carrocerías Hermanos Becerra is a 100% Mexican company founded in 1984.

In the beginning it only specialized in the repair of bodies, however over the years they began to manufacture bodies for urban transpor busest; They later entered the short and medium distance segment with their B330 and B340 bus models. In the last quarter of 2021, the brand seeks its consolidation in the BRT segment by launching the electric version of the e-Urviabus bus in collaboration with SCANIA.

Mastretta cars is a Mexican automotive design studio and company established by Mexican industrial designer Daniel Mastretta at Mexico City in the year 1987. He began working with car designers when he had bought his first car, which was a small car. His work with car designers led to him designing several models of cars for clients such as Mercedes Benz and Jaguar. The cars he designed are renowned for their style, unique design, high quality construction, and stylish looks.

His first car was a little car which Mastretta designed to have a small engine and light weight, as most cars were then. However, after this first car failed to sell, he had to think of something that would make a better sales pitch. He decided to design a car that had no bodywork, but had a long hood, and an engine, which was a small displacement engine, to give him a good sales pitch for his new design. With this car, he was able to create a name for himself and set his sights on producing more of these small cars.

View: https://www.youtube.com/watch?v=bg5B-KWpZog

View: https://www.youtube.com/watch?v=vgE5uuoATEA

View: https://www.youtube.com/watch?v=rF9Y5mXD4zU

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

GHIA, technology for sharing.

GHIA is a Mexican Computer, Electronics and Accessories brand with 12 years in the market, offering quality technology within everyone's reach, recognized for its excellent cost/benefit ratio, quality service and currently one of the best-selling brands across of the IT Distribution Channel.

We work hand in hand with strategic allies such as Microsoft, Intel, AMD, Mediatek, among others, building a solid and close relationship that allows us to have the best technology in each of our products.

We have 26 product categories: Powerbanks, Storage, Wearables, Backpacks, Accessories, Cellphones, Personal audio, Tablets, Laptops, 2 in 1, AIO, Desktop, Keyboards and mouse, Monitors, Video Surveillance, Alarms, Wiring, Audio, POS , Televisions, Antennas, Mounts, Mini PC, Adapters, Cleaning Products, Energy.

These units make up our extensive catalog with more than 500 products. Our offer grows and is constantly updated according to the needs of the Mexican market.

GHIA products have a nationwide presence with our more than 25 thousand distributors, e-commerce and Marketplace, as well as in the main Retail chains.

All our products have a 1-year warranty and a 3-year warranty on monitors.

GHIA tecnología

www.ghia.com.mx

The Vorago PAD-7 tablet evolves inside so that you have your applications really at hand.

Vorago develops quality and cutting-edge technological products within the reach of any user. It was incubated by a group of leading companies in the IT, supply chain and distribution industry with more than 30 years of experience.

Vorago operates globally with an assembly line and corporate offices in Guadalajara, Jal. Mexico. We are the global technology brand with the widest offering of innovative technology products, segmented into the categories of:

Equipment

Audio

Equipment

Keyboard - Mouse

Equipment

Calculation

Equipment

Tablets

Equipment

E-Mobility

Equipment

Accessories

Equipment

Energy

Equipment

Backpacks

Equipment

Gamer STG

Our responsibility is to provide timely information to our users on technology issues in order to give them the necessary tools to make an intelligent choice.

Vorago - Audio, Cómputo, Tablets, Monitores, Accesorios, E-Movilidad, Mochilas, Gamer

En Vorago® desarrollamos productos tecnológicos de calidad y vanguardia al alcance de cualquier usuario.

Lanix has 33 years of history; From Hermosillo, Sonora, this proudly Mexican brand has managed to establish itself in the most competitive markets in the world to offer computers, tablets and smartphones.

Jorge Noriega, Director of Technology and Graciela Domíngez, Director of Marketing at Lanix, chat with Armando Reygadas and Edgar Rodríguez about the challenges faced by a technology company.

View: https://www.youtube.com/watch?v=AgFQxZdf82o&list=PLq9uMmDwlWrlCnyB2Xe_LvwXsDMa9qRj1

View: https://www.youtube.com/watch?v=hF35MgeSHas

View: https://www.youtube.com/watch?v=pm54_BkAboQ

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

PRAIA E-BIKES is a Mexican brand with a positive spirit and full of freedom, the ideal electric bicycles for those who want to surf the electric wave in the city. Praia is designed and thought about the cities of our country. It is the perfect balance between design and quality for alternative mobility.

PRAIA Archives

Conoce PRAIA, las e-bikes que combinan libertad y energía positiva | Bicis eléctricas plegables de PRAIA, para viajes divertidos. Compra con Mandarina.bike

View: https://www.youtube.com/watch?v=fQznlKoxCrs

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

Koblenz is an Mexican international company that designs, manufactures and markets industrial and domestic equipment, both small and large, as well as energy control solutions.

View: https://www.youtube.com/watch?v=PJE0z9J4pVQ

View: https://www.youtube.com/watch?v=PJE0z9J4pVQ

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

The Argentine electric car brand Volt lowered the prices of 3 models and expands its production plant

The brand that manufactures in Córdoba announced an investment to expand car production, while launching a series of offers for its three models

IPROFESSIONAL | CARS | CHANCE

By Guillermina Fossati

03/21/2024 - 4:20 p.m.

The Argentine electric car brand Volt lowered the prices of 3 models and expands its production plant

In the midst of the drop in 0km sales, different automakers announced discounts and financing for their models, in order to activate operations. And one of those that joined this "wave" was Volt Motors, which in addition to lowering the price of electric cars, announced its next venture: it will expand the production line to manufacture more units in 2024.

Manufacturer of two electric city cars approved for public roads and one for use in closed places, the brand based in Córdoba made these two great announcements and committed to having an active year, also adding more sources of work.

In the case of discounts for 0km, it is an action that is giving a lot of results to the terminals, in the midst of consumer uncertainty, and that is why at Volt it will be in force with discounts of around 15 percent.

At the same time, the brand seeks "opportunities" to put the models among the most economical cars of the month, compared to direct competitors such as Tito and Sero Electric (they start at $15 million), and in the same order as massive cars. , such as the most economical ones where Toyota Yaris and Fiat Cronos are found (from $17 million average), among others.

How much do Volt electric cars cost?

Starting with the discounts, according to the brand's advertisements, for any of the three models of Volt electric cars the prices are as follows:

Volt e1 - Power Long Range: $23,990,000 (previously $26,660,000)

Z1 - Power Long Range: $17,140,000 (previously $19,040,000)

W1 - Power Long Range: $22,280,000 (previously $21,750,000)

Volt has two models enabled for use on public roads.

Volt has two models enabled for use on public roads.

As for the financing line, it offers a loan with Badlar with a variable rate for up to 60 months.

What are Volt electric cars like?

Volt has two models for use on public roads and one in closed spaces.

As for those that can circulate on public roads, the W1 and e1, have a 14 kW engine in common and reach a maximum speed of 80 km/h (electronically limited). The battery is LiFePO4 type with a capacity of 20 kWh and has a range of 200 km. The recharge time from a domestic outlet is 10 hours. And the maximum speed of 105 km/h.

The Volt W1 is an electric utility vehicle with capacity for one adult passenger and a maximum load of 760 L, for use on public roads. It has LED lights, electric exterior mirrors, 7" digital screen and VOLT OS operating system with touch driving commands on the screen. It has air conditioning (optional) and heating, electric windows, 4-wheel disc brakes.

The Volt e1 is a car for urban use that reaches a speed of 105 km/h and the autonomy is 200 km. It is a car to travel from home to work, to the gym, to meetings. On a 6.6kW Wallbox 7kW/32A charger it charges in 4 hours.

The Volt is one of the domestically produced electric cars with the greatest autonomy.

The Volt is one of the domestically produced electric cars with the greatest autonomy.

In general, the cars are designed for easy charging in a 220 outlet and also charging in Wall Box and chargers on public roads.

According to the company, they save 90% in the cost of operation and maintenance compared to vehicles operated with fossil fuels; and can transport up to 300 kg of cargo, with 750 liters of volume.

With deceleration and regenerative braking (it allows part of the vehicle's kinetic energy to be reconverted into electrical energy again and stored in the battery.

Volt's venture to manufacture more

In addition to launching discounts, Volt presented an investment plan to expand local production and help its business, born almost 4 years ago, grow further.

The company announced an investment of $1.5 billion that will allow it to double its installed capacity and produce 3,000 vehicles per year in its Hub located in Ciudad Empresaria, in Córdoba Capital.

The investment plan has been carried out since the beginning of this year, will be completed in 120 days and includes raising its industrial warehouse to 7,000 m2, in addition to the incorporation of state-of-the-art Italian technology and robotics, for the automation of the machining of parts and assembly. Of units; a new production line store

VOLTmotors - Making the Future: Primer Vehículo Eléctrico Argentino

Descubre VOLTmotors, la marca pionera en la creación del futuro de la movilidad sostenible en Argentina. Conoce nuestro orgulloso logro de ser el primer fabricante de vehículos eléctricos diseñados y producidos en Argentina. ¡Elévate al futuro con VOLT!

voltmotors.com.ar

Se amplía el emprendimiento de Volt para fabricar más autos eléctricos y rebaja precios de 3 modelos

La marca que fabrica en Córdoba anunció una inversión para ampliar la producción de autos, al tiempo que lanzó una serie de ofertas para sus tres modelos

View: https://www.youtube.com/watch?v=BcTaaCPaz1M

QSM Semiconductores opens development center in Querétaro

26 February, 2024QUERETARO - QSM Semiconductores inaugurated a development center in Querétaro in which it invested US$3 million and which seeks to put Mexico on the semiconductor map.

In an event attended by state authorities and company executives, Marco Antonio Del Prete Tercero, Secretary of Sustainable Development, highlighted that, with this investment, the entity drives a new industry niche with design, programming and packaging, which is what adds value to the product.

"Querétaro is a pioneer in the semiconductor industry," said the Secretary, who pointed out that the government will continue to promote manufacturing, since it represents 30% of the state's Gross Domestic Product.

He also emphasized that this type of investment adds value to the economy. Now they are looking to go to the next level through knowledge, which is why they are making alliances with research centers.

Alejandro Franco, CEO of QSM Semiconductors, commented that they are a Queretaro-based company with a clear objective: to put Mexico on the semiconductor map, from design to manufacturing.

The executive explained that this chip engineering center will employ more than 60 specialists. It is worth mentioning that QSM Semiconductors develops products for the electronics, audio, video, office, gaming and toy industries.

QSM Semiconductores opens development center in Querétaro - MEXICONOW

QSM Semiconductores inaugurated a development center in Querétaro in which it invested US$3 million and which seeks to put Mexico

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

Pauny S.A. is an Argentine company that is today recognized in the metalworking industry, it is located in its main plant in the City of Las Varillas in Córdoba, Argentina.

With more than 75,000 square meters covered and more than 500 highly qualified employees and a production that provides solutions in high and medium power tractors, road and transportation machinery, Pauny stimulates sustainable development.

Zanello

Construcciones Metalúrgicas Zanello is an Argentine company from Las Varillas (Córdoba), dedicated to the manufacture of tractors, road equipment and implements.

Zanello Tractor

Construcciones Metalúrgicas Zanello was founded in 1951 by Pedro Zanello.

He began manufacturing bodywork equipment for trucks and then dedicated himself to tractors, irrigation equipment, forklifts, generator sets, power sets and forage equipment.

In the 1970s it began the production of self-propelled road machines and in the mid-80s it started manufacturing engines, transmissions, fuel injection pumps and water pumps.

Currently, the company manufactures tractors, motor graders, front loaders, backhoes, excavators, mini loaders, tractors, dump trucks, irrigation tanks and weed removers, among other products.

View: https://www.youtube.com/watch?v=NkIYYDeNDLM

View: https://www.youtube.com/watch?v=_aMUlDQm4js

With more than 75,000 square meters covered and more than 500 highly qualified employees and a production that provides solutions in high and medium power tractors, road and transportation machinery, Pauny stimulates sustainable development.

Zanello

Construcciones Metalúrgicas Zanello is an Argentine company from Las Varillas (Córdoba), dedicated to the manufacture of tractors, road equipment and implements.

Zanello Tractor

Construcciones Metalúrgicas Zanello was founded in 1951 by Pedro Zanello.

He began manufacturing bodywork equipment for trucks and then dedicated himself to tractors, irrigation equipment, forklifts, generator sets, power sets and forage equipment.

In the 1970s it began the production of self-propelled road machines and in the mid-80s it started manufacturing engines, transmissions, fuel injection pumps and water pumps.

Currently, the company manufactures tractors, motor graders, front loaders, backhoes, excavators, mini loaders, tractors, dump trucks, irrigation tanks and weed removers, among other products.

View: https://www.youtube.com/watch?v=NkIYYDeNDLM

View: https://www.youtube.com/watch?v=_aMUlDQm4js

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

HACEB, one of the largest appliance companies from Colombia, has built a path towards sustainability, which has led them to define themselves as a conscious and sustainable organization, which seeks balance between its economic axis, its environmental actions and its social performance. , which is constantly innovating to continue offering sustainable solutions to consumer needs.

With a firm commitment to reducing the environmental footprint, they have integrated principles of eco-design and sustainable innovation. Through a specialized methodology, they direct their efforts toward creating future designs that minimize their impact on the environment. This approach covers all phases of the life cycle of its products, from the selection of raw materials and efficiency in the use of parts, to production and extension of useful life once in the hands of the consumer.

It was 1940, when a small workshop dedicated to electrical repairs was opened a few meters from the Municipal Palace of Medellín. Right there, at Taller Eléctrico Medellín, was where the history of this large industrial park began to be written where we manufacture household appliances and gas appliances such as refrigerators, stoves, washing machines, among other products in the municipality of Copacabana, Antioquia, a factory of dreams where we generate well-being and progress for all.

Today, this rhombus is in the home and hearts of millions of Colombian families. Don José María Acevedo, founder of Industrias Haceb, achieved what seemed unthinkable: overcoming ingenuity over difficulties, thinking beyond all limits, transforming his destiny and consolidating a company that today is a national pride.

Today we have been one of the family for more than 82 years and transforming cooking, refrigeration, washing, water heating and air conditioning products into comprehensive solutions, reaching Colombians and more than 20 countries based on innovation, the generation of surprising experiences, cultural transformation and operational excellence.

The Mexican company CRIOTEC, which works in the commercial refrigeration sector, will be the first company in the country to use the "Green Label", the label that demonstrates the use of renewable energy supplied by Enel Green Power

Mabe is a Mexican brand with partial ownership by Hiar from China of 48% keeping the remaining 52% in Mexican hands. It produces and designs home appliances.

mabe.cc

mabe.cc

View: https://www.youtube.com/watch?v=-VoZdTzP0wA

View: https://www.youtube.com/watch?v=LHRNGbz9Bcg

View: https://www.youtube.com/watch?v=lk2xDCRV3cM

With a firm commitment to reducing the environmental footprint, they have integrated principles of eco-design and sustainable innovation. Through a specialized methodology, they direct their efforts toward creating future designs that minimize their impact on the environment. This approach covers all phases of the life cycle of its products, from the selection of raw materials and efficiency in the use of parts, to production and extension of useful life once in the hands of the consumer.

It was 1940, when a small workshop dedicated to electrical repairs was opened a few meters from the Municipal Palace of Medellín. Right there, at Taller Eléctrico Medellín, was where the history of this large industrial park began to be written where we manufacture household appliances and gas appliances such as refrigerators, stoves, washing machines, among other products in the municipality of Copacabana, Antioquia, a factory of dreams where we generate well-being and progress for all.

Today, this rhombus is in the home and hearts of millions of Colombian families. Don José María Acevedo, founder of Industrias Haceb, achieved what seemed unthinkable: overcoming ingenuity over difficulties, thinking beyond all limits, transforming his destiny and consolidating a company that today is a national pride.

Today we have been one of the family for more than 82 years and transforming cooking, refrigeration, washing, water heating and air conditioning products into comprehensive solutions, reaching Colombians and more than 20 countries based on innovation, the generation of surprising experiences, cultural transformation and operational excellence.

The Mexican company CRIOTEC, which works in the commercial refrigeration sector, will be the first company in the country to use the "Green Label", the label that demonstrates the use of renewable energy supplied by Enel Green Power

Mabe is a Mexican brand with partial ownership by Hiar from China of 48% keeping the remaining 52% in Mexican hands. It produces and designs home appliances.

Origen y Expansión | Mabe Corporativo

Empresa mexicana de línea blanca líder en Latinoamérica con el compromiso de ofrecer productos de excelente calidad.

View: https://www.youtube.com/watch?v=-VoZdTzP0wA

View: https://www.youtube.com/watch?v=LHRNGbz9Bcg

View: https://www.youtube.com/watch?v=lk2xDCRV3cM

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

Jade 3D printer features what you should know about the Mexican brand

View: https://www.youtube.com/watch?v=VuO_l8j55wU

View: https://www.youtube.com/watch?v=VuO_l8j55wU

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

The Brazilian national automotive industry, in general, is marked by many sadnesses and disappointments as the vast majority of them were unable to survive the turbulent decades of the 80s and 90s when the country had economic instability, but fortunately there are exceptions and one of them is the Gaucho corporation Randon! Randon is famous for its trailers, also called semi-trailers, and is considered one of the largest manufacturers of its kind in the world! But the company also works in various areas of the automotive and transport sectors, even manufacturing carriages for trains!One of the areas in which the company worked for many decades was the heavy machinery sector, making tractors and even large dumpers for mining. The company also has a large presence in the agribusiness sector producing fruits and dairy products.Currently the company has 30 factories and sells products to 120 countries, but its beginnings were very humble, with its beginnings being a simple blacksmith shop run by brothers Hercílio and Raul Anselmo Randon who continued the trade after their father retired.

View: https://www.youtube.com/watch?v=RM_Wp8PPxJ8

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

IUSA is a Mexican brand that builds home appliances, in this case are electric Hydroblaster Water Cannons

IUSA-Total drill

IUSA vaccum cleaner

View: https://www.youtube.com/watch?v=n7LrergI8fE&list=UULFt2JxYdlCygc11tfH6s0sWA&index=14

View: https://www.youtube.com/watch?v=NcwyhDM3oZA&list=UULFt2JxYdlCygc11tfH6s0sWA&index=41

View: https://www.youtube.com/watch?v=F3_P6ql2-GE&list=UULFt2JxYdlCygc11tfH6s0sWA&index=8

¿Cuántas marcas mexicanas fabricantes de equipos de cómputo conocemos? Parte I - COMPAX - KiGaRi CyD.com

Por lo general, cuando realizamos esta pregunta la mayoría de personas responde, ninguna. Al darle continuidad a la conversación se les asesora y se les mencionan las marcas mexicanas de equipos de cómputo:

www.kigaricyd.com

www.kigaricyd.com

Last edited:

- Joined

- Jul 3, 2024

- Messages

- 432

- Likes

- 872

ATECHNIK"Automatische Technik is the first Mexican company to manufacture delta-type Industrial Arms

View: https://www.youtube.com/watch?v=oqu_irtV-t0

Latest Replies

-

Indian Special Forces

- Airborne22

-

Indian Small Arms and Weapons

- IWIarad11

-

Infrastructure

- haldilal

-

-

DRDO and PSU's

- Blood+

-

Super & Quantum computing in India

- FalconSlayers

-

Israel - Hamas Conflict

- Lcafanboy

Trending Threads

Donate via Bitcoin - bc1qpc3h2l430vlfflc8w02t7qlkvltagt2y4k9dc2