The Tatarstan business resource BUSINESS Online published an article by Timur Latypov entitled "On the verge of an adventure? Kazan Helicopters is restarting Ansat as early as 2025 and making the first batch of Mi-34s", which reports on the extensive plans of Kazan Helicopters JSC (KVZ, part of Russian Helicopters JSC of the Rostec State Corporation) for 2025, including the construction of nine serial Mi-38 helicopters and the start of serial production of an "import-substituted" version of the Ansat helicopter and another updated version of the light Mi-34 helicopter. Given the numerous problems with these helicopters, as well as the uncertainty surrounding the serial production of engines for them, it is not surprising that even the author of this article calls these intentions of Kazan Helicopters "adventurous".

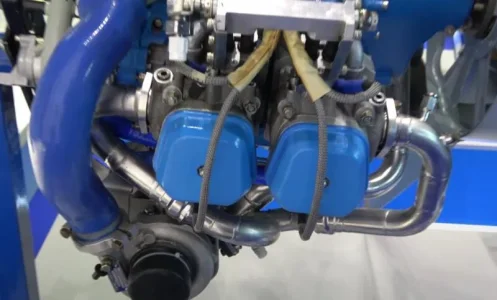

Assembly of the Ansat helicopter at the Kazan Helicopter Plant (KVZ) of the Russian Helicopters holding company (c) BUSINESS Online

The Kazan plant is quietly making progress in terms of helicopter types. The main problem area is the new engines

After an almost 10-year break, KVZ is once again becoming a showcase of Tatarstan's achievements. As it turns out, the plant not only carried out a large-scale (estimated at 25 billion rubles) modernization, but has already planned its continuation - for about 15 billion. "Something incredible," some experts admire the transformation of the enterprise, and others say the same thing, but in the opposite tone - so ambiguous are KVZ's plans for the production of helicopters, primarily the Mi-34. BUSINESS Online looked into the insider news from the workshops.

KVZ wants to build another plant

The recent conversation between Russian President Vladimir Putin and Tatarstan Rais Rustam Minnikhanov about the plant's prospects turned out to be unexpectedly substantive for a standard report on the republic's economic development.

— KVZ has carried out major modernization: a machining center, an assembly center, and, most importantly, an educational center, — Minnikhanov said.

— The revenue is good — almost 60 billion rubles, — Putin noted.

— Yes. The most important thing is that now the Ansat already has a Russian VK-650 engine. The Mi-38 is new, more than the Mi-8.

— With high speeds.

— Yes, and its speed is over 300. And the Mi-34, also a Robinson type, is also a very good machine.

Judging by the information from BUSINESS Online sources in the aviation industry, Rustam Nurgalievich had a lot to talk about in detail. It is common knowledge that new final assembly shops, a flight test complex (FTC) and a production and training center have started operating, but, according to our sources, there is an important clarification: a new production system is being implemented. There was a post method, when a helicopter is assembled in one area with a change of assembly teams depending on the operation being performed. Instead, there is flow production, when the product moves through assembly areas. Each type of helicopter has its own line.

Machining has been radically transformed - more than 200 machining complexes have been purchased (in addition to the fifty already available). Commissioning is currently underway. It is noteworthy that machining will work not only at KVZ, but also at all enterprises of Russian Helicopters (VR).

“Mechanics were a sore point,” says the source. “It was because of them that we were behind schedule, sometimes for several months. Now there will be no problems for Kazan, Kumertau, Arsenyev or Perm." He believes that centralization is justified: "If these machines were scattered across factories, there would be no effect."

According to known data, the modernization cost 25 billion rubles. Interestingly, according to the source, today a decision has been made to continue it, at least in the form of one additional production - products from composite materials. Our interlocutors indicate that the cost of the project is approximately 15 billion rubles. "BUSINESS Online" asked BP to comment on this and other information from sources, but at the time of publication of the article had not received a response.

"The new mechanical production is something incredible," Alexander Lavrentyev, former (in 1984-2007) general director of Kazan Helicopters, president of the association of enterprises and industrialists of the Republic of Tatarstan, assessed the transformation of the plant in a conversation with "BUSINESS Online". - On the other hand, this is how it should be. When the plant bought Japanese machining complexes in 2010, it immediately closed two mechanical shops with conventional machines, turners, grinders, milling machine operators - they were no longer needed. This is what labor productivity is. The West is moving forward by leaps and bounds because it is updating its machine tools, while 60 percent of ours are 20 years old. And a composite plant is needed, no question. We dreamed about it at one time, but our finances did not allow it. I think the plant will be two heads ahead compared to others."

The most expensive helicopter of KVZ

Finally, information is appearing on one of the long-term construction projects of the Russian aviation industry - the Mi-38. Let us recall that work on it began in 1988, the first flight took place in 2003, and in its current form (with Russian engines instead of Canadian ones), the machine took off in 2013. Together with the prototypes, 16 helicopters were produced, of which 11 are flying (including those of the Ministry of Defense and the F

CO), but operational details are not disclosed.

According to the source, the plan for 2025 is to produce 9 Mi-38 at once - KVZ has never produced so many helicopters of this type in a year. According to our interlocutor, this is a renewal of the contract with the Russian Emergencies Ministry. The agreement for 14.7 billion rubles was signed in July 2021. The ministry was supposed to receive the launch vehicle in 2023, the rest - in 2024, but the contract was suspended after the crash of the experimental Il-112 transport aircraft in August of the same year. The cause of the crash was an engine fire, and the Il-112 had the same engine as the Mi-38 - the TV7-117V aircraft version.

This engine immediately gained a reputation for being problematic, but it is believed that today the childhood illnesses of all its modifications have been eliminated. This should be evidenced by the dispatch of two Mi-38s in May 2024 for lead operation to the Aviation of Kolyma airline, the resumption of tests in March of the same year under the Il-114-300 program (the aircraft is equipped with the TV7-117ST-01) and the first flight of the next experimental Il on March 30, 2025.

The main work on the TV7-117V is now related to confirming the engine's service life, the source says. Tests were conducted in 2024–2025, according to the results of which it is planned to increase the service life from 360 hours to 775, and in the future the task is to ensure a service life of 2,140 hours. "The release of the TV7-117V version is now a priority," Oleg Panteleev, executive director of the industry agency AviaPort, outlined the situation in an interview with BUSINESS Online. — While other versions (for the Il-114-300 and TVRS-44) are only in demand for R&D work, the helicopter engine is already in serial production. The UEC enterprises involved in the cooperation have partially completed and continue technical re-equipment for a large series, including a helicopter and two aircraft versions."

Be that as it may, the Mi-38 is still a new (and rather raw) helicopter; it has yet to fully enter the market.

It is worth noting the specifics of the Mi-38 for the Ministry of Emergency Situations. It was reported that the Mi-38PS (search and rescue) has an increased flight range and a significant amount of special equipment (and therefore an increased takeoff weight), the ability to land on icebreakers, transport the sick and injured, and land rescuers non-stop and by parachute. The Ministry of Emergency Situations planned to use the Mi-38PS in the Arctic zone and the waters of the Northern Sea Route. The above-mentioned nine should form aviation links at five points, and later along the entire length of the NSR, i.e. the purchase of Mi-38 will continue (according to sources, so far we are talking about 25 machines). Considering the importance attached to the military and other presence in the Arctic, the production program of KVZ for Mi-38 is at the forefront.

It should be noted that Mi-38 is the most expensive product of KVZ: more than 1.5 billion rubles per machine, while the most advanced Mi-8 costs 3 times less.

When the new Ansat will take off

A fair amount of sensationalism is present in the source's message regarding the Ansat program. The first flight of the helicopter, consisting only of Russian components, is scheduled for early summer, but the main thing is that the production plan for 2025 is three Ansats.

Let us recall that in March 2022, Pratt & Whitney Canada stopped supplying PW207K engines to Russia, which were chosen for the Ansat at the time. Instead, it was decided to install VK-650V engines developed by UEC-Klimov. All other imported components of the helicopter are also being replaced with domestic ones. According to known information, the concept of maximum use of existing Russian products was chosen to speed up the process. In parallel, a search is underway for partners capable of creating analogues of foreign components. There were no analogues for such key components as the engine, control system elements, and autopilot servos. Much has changed seriously in the helicopter, some beyond recognition, which, by the way, also affected the appearance.

No matter how you look at it, this is a rebirth for the Ansat program, and it depends primarily on the engines. And there is something to express concern about here.

The creation of a domestic engine for the Ansat has been discussed for over 20 years, there were real projects, but for some reason they were not given a go, and today they declare the readiness of the VK-650V, which began to be created only in 2019 (the type certificate was issued on February 7, 2025).

The design resource of the VK-650V, like the PW207K, is 3 thousand hours, but it will be developed in stages. Now the designated resource is 74.5 hours. Estimates of the engine from sources in the industry vary radically: from "very successful" to "requires a complete redesign." Only flight tests and operation will show who is right. Ansat with VK-650V at the Flight Testing Center since the end of 2024, and rumors every now and then predict the first flight "any minute now", but, as one of the sources says, "there is still no permission to fly." He attributes this to the claims of the Central Institute of Aviation Engines.

In any case, the Ansat with a new engine will not take place today or tomorrow, and there will be less trust in it than in its brothers with the PW207K, and the engine's maturation period will be difficult for KVZ. "Yes,

right now they will be able to make 20-30 engines, but a full-scale series is still a long way off,” the source is sure. And at the same time, as our interlocutor points out, there will be a queue for the VK-650V. This engine will also be installed on the Ka-226 (instead of the French Arrius 2G1), which is planned to be manufactured at the Ulan-Ude Aircraft Plant. But the second main consumer of the VK-650V is not it, but the Kazan project of the light Mi-34.

Mi-34: why shouldn't helicopter manufacturers consult with helicopter pilots?

Regarding the Mi-34, our source already gives quite sensational information: the 2025 plan is 15 helicopters. This is despite the fact that the decision to build this type at the Kazan Helicopter Plant was made only at the beginning of the summer of 2024.

It is important to remember that the development of the Mi-34 began in 1980 with the M-14V-26 piston engine. The first flight took place in November 1986, but everything was ruined by the collapse of the USSR. Testing was resumed at the end of 1992, and the Mi-34 received a certificate in 1995. It was planned to produce 400 machines in 1992–2000 (with a projected need of 2,000), but only 30 were manufactured. The machine was remembered in the early 2010s, but the project was closed in 2012, largely due to the lack of a good domestic engine.

Now the project has been revived. The Mi-34 is seen as a replacement for the American Robinson (piston R44 and gas turbine R66, there are about 600 of them in the Russian Federation) that is widespread in Russia — the most popular family of general-purpose helicopters in the world. Under sanctions, Robinsons flying to Russia have problems with maintenance and repair. Yes, Russia has developed gray schemes for the supply of spare parts and used helicopters, but it is becoming increasingly difficult to service the fleet. “Anyone whose engine resource has expired is forced not even to repair it at an exorbitant price, but to buy it through third parties,” Magomed Zakarzhaev, an adviser to the general director of the Kazan Aviation Enterprise (before sanctions, an authorized service center for Robinson Helicopter Company, Bell Helicopter Textron), gave an example in an interview with BUSINESS Online. Given the power of the VK-650, it is planned to create several modifications of the Mi-34 - with a takeoff weight from 1.5 tons to 2.1 tons and a capacity of 3 to 6 passengers (plus one pilot). In short, it turns out to be a completely new helicopter, but it seems that BP has decided to go the route of additional certification to speed up the process, as if it were a modernization of the classic Mi-34. According to the source, approval of the main change is expected to be received at the end of August. So far, one modification is planned - a four-seat (Mi-34M1), and a five-seat Mi-34M2 is under development. According to our interlocutor, it was possible to achieve a cost price comparable to the Robinson R66. A new R66 costs $1.34 million, a used one - $300-600 thousand, and a used R44 can be bought for $180 thousand. "But of course, we don't have Robinson yet," the source admitted. "Now they will roll out these 15 machines and see what happens." Will KVZ be able to pull off such a solid batch of completely new helicopters? According to the source, all contracts for the equipment have been concluded. Yes, there are nuances, but this is a normal situation. According to another of our interlocutors, the expectations are too optimistic, bordering on adventurous: he is sure that it will be possible to organize serial production of, for example, the rotor swash plate and other necessary units no earlier than 2027. It is interesting that the Mi-34 simulator has already been ordered, it will be installed at Kazan Helicopters.

“They will definitely be interested in the Mi-34,” Zakarzhaev is sure. “But a lot depends on what resources are assigned. The helicopter is new, they will initially be small. Under what conditions will they be extended - for money or automatically? It’s a pity that there is almost no information about the Mi-34. Manufacturers should still consult with potential consumers, but I have not yet heard of Kazan Helicopters collecting future buyers. We could have some wishes that can be taken into account immediately and then not suffer, as was the case with the same Ansat... The Kazan aviation enterprise is ready to act as a base for operational tests. Firstly, the plant is nearby. Secondly, we patrol oil and gas pipelines, and the Mi-34 could be ideal for this role. True, drones are hot on their heels, but it is not yet clear how far this unmanned approach will go."

What does all this mean?

Kazan has long been talking about the fact that for the sustainability of KVZ, a wide model range is needed so that one type could replace another that is no longer in demand. For example, the Mi-38 was seen as an expensive one-off helicopter, the sales of which would allow the plant to wait out the disruptions in demand for mass-produced machines.

And now the range is formed: Mi-8, Ansat, Mi-38, Mi-34 - no one else has such a variety. On the other hand, this will seriously complicate the plant's life. If earlier the Kazan people had one machine that was well-developed in production - the Mi-8 - and one that was developed quite well - the Ansat in its original form, now the enterprise receives in addition to the "eight" three new, as we found out, types, that is, four almost non-intersecting nomenclature of components. And in post-Soviet times, purchased products, i.e. cooperation between