Mexico seeks US help in cutting back on imports from China

South China Morning Post

Thu, October 10, 2024 at 6:30 PM GMT+9·4 min read

7

The government of newly inaugurated Mexican President Claudia Sheinbaum plans to collaborate with the United States to reduce its reliance on Chinese supplies, The Wall Street Journal reported this week.

Luis Rosendo Gutierrez, Mexico's deputy secretary of commerce, told The Journal in a report on Tuesday that Sheinbaum - who came into office on October 1 - intended "to focus on supporting our domestic supply chains".

According to Gutierrez, informal discussions have already been held with US semiconductor manufacturers, carmakers, and space technology companies to replace imports of goods and components from China, Taiwan, Malaysia and Vietnam.

Do you have questions about the biggest topics and trends from around the world? Get the answers with

SCMP Knowledge, our new platform of curated content with explainers, FAQs, analyses and infographics brought to you by our award-winning team.

Analysts, however, noted the challenges of decoupling the Mexican and Chinese economies - even as US concerns about Mexico's engagement with China could complicate US-Mexico relations.

The Journal also cited an internal Mexican government presentation, which identified the risks of maintaining robust trade ties with the US amid "a new consensus" in Washington supporting protectionist policies.

The document stated that Mexico might find itself in the middle of "a trade war between the US and China".

Mexico's trade secretariat could not immediately be reached for comment on Gutierrez's statements.

The Journal report follows Mexico's long-standing grievances over Chinese trade practices. Historically, Mexico has consistently run a trade deficit with China - a gap offset by the trade surplus generated under the free trade agreements with the United States and Canada.

According to Statista, Mexico imported US$114 billion worth of goods from China, while exports amounted to only US$9.15 billion.

In July, Mexico's finance secretary, Rogelio Ramirez de la O, voiced concern over the trade imbalance, noting that China had increased its global exports from 3.8 per cent to 14 per cent in little more than two decades "and this increase has largely come at North America's expense".

China's foreign ministry responded to the Journal report, asserting that bilateral trade with Mexico had "brought tangible benefits to the people of both countries" and urged Mexico to foster favourable conditions for economic and trade interactions.

Despite these reassurances, Mexico's statements cast doubt over future trade with China, especially as discussions loom regarding revisions to the United States-Mexico-Canada Agreement (USMCA) - the free trade agreement Mexico maintains with its northern neighbours. The formal review is set for 2026, but talks are expected to begin as early as the second half of 2025.

Analysts said that Mexico would face difficulties balancing its trade priorities with US diplomatic dynamics.

At an event hosted by the Wilson Centre in Washington on Tuesday, former Mexican and American diplomats, along with trade experts, discussed the unclear nature of US "red lines" concerning trade with China.

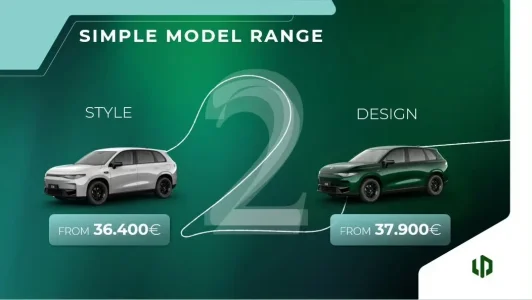

For example, Martha Barcena, a former Mexican ambassador to the US, noted that electric vehicles - a major concern for US policymakers - remain a grey area in trade relations. Despite recent US sanctions and tariffs on Chinese exports, the sector is not covered by the USMCA.

"Chinese presence in the auto sector has been growing in recent years, particularly in auto parts," Barcena said. "This raises many questions about how Sheinbaum's administration will handle nearshoring and trade in the auto industry."

Last week, a bipartisan group of 20 US lawmakers sent a letter to Sheinbaum, urging her to address "national security concerns posed by internet-connected vehicles produced by Chinese auto makers in Mexico".

The lawmakers expressed concern about plans by the Chinese carmaker BYD to open a factory in Guadalajara, Mexico.

Roberta Jacobson, US ambassador to Mexico from 2016 to 2018, said that a growing number of Mexican academics and entrepreneurs were advocating for a triangular strategy allowing Mexico to benefit from trade with both China and the US

"The problem with that," Jacobson said, "is that in the US Congress, or in Washington in general, there is one truly bipartisan issue these days, and that is China.

"So the notion that the US will accept a triangulation strategy as leverage simply isn't going to work."

This article originally appeared in the

South China Morning Post (SCMP), the most authoritative voice reporting on China and Asia for more than a century. For more SCMP stories, please explore the

SCMP app or visit the SCMP's

Facebook and

Twitter pages. Copyright © 2024 South China Morning Post Publishers Ltd. All rights reserved.

Copyright (c) 2024. South China Morning Post Publishers Ltd. All rights reserved