- Joined

- Jul 1, 2024

- Messages

- 853

- Likes

- 3,975

I'll tell the you problem with your thought process & approach . This bit of news you're posting about the Kaveri achieving ~ 1400°C is unverified for the GTRE given severe limitations of testing & calibration facilities will not be able to verify these parameters for a substantial amount of time if they go in for a change of blades / blisks.

What this means is they've conducted preliminary bench tests for limited periods of time . It was the same with the Kaveri engine ~ 2010 where bench tests were fine , also HAT tests but the moment this TF was mated onto the FTB & tested , it developed the now legendary screech , flutter & other issues with the AFB (?) .

It's only once they get it tested on an FTB they'd know where exactly they stand . For that , the previous experience is something which will have more than necessary bearing on their decision making process. What if this model also develops similar or related issues ? That'd mean they return to the drawing board & start reworking the design .

The last time it took them a good 8-10 years plus SAFRAN consultancy before they overcame these issues. And time is a luxury they cannot afford especially since the project has already dragged on for ~ 4 decades now for little fault of theirs .

Hence discretion is the better part of valour. They went in with tried tested & proven solutions of lesser calibre instead of experimenting & here we are .

Agreed to most part. I searched alot but didn't find anything significant to say dms4 is proven tested certified but rather found other thing thing abt it which I have already shared on this threads that's all is there in public.

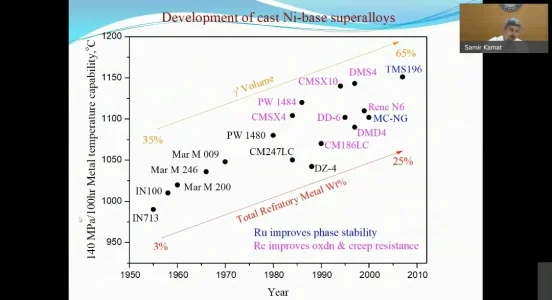

the sameer kamat chief of drdo provided this data dms4 i suppose they have performed limited testing given what infra they. But still impressive then.

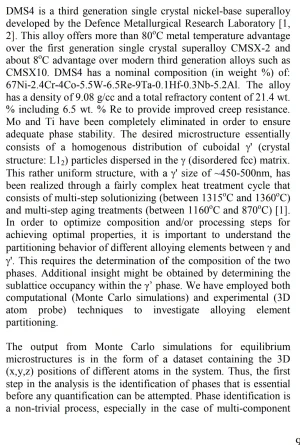

This one is from dmrl folks themselves.

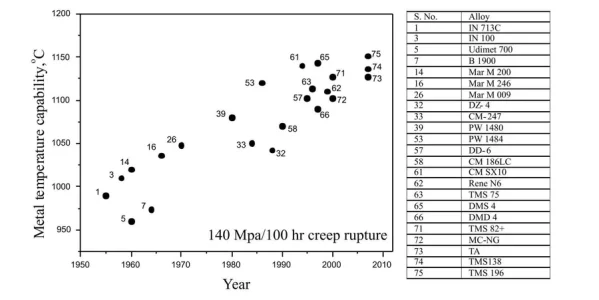

DMS4 is in same league as 3rd gen CMSX10, Rene N6, and TMS75. DMS4 offers 1140°C TET compared to 1104°C of Rene N6 (f414), 1135°C of CMSX10, 1110°C of TMS 75 and 1150°C of TMS 196.

This raw number i.e without TBCs & intricate coolings channels.

Dms4 is in same league if we had to go by the papers published by dmrl folks papers. Also they have patented it.

Whatever they made public in those parameter i suppose dms4 is quite advance 3rd gen alloy.

And this was developed in 2013.

I have heard it was produced in existing facilities of hal koraput and with existing YSZ coating.

But I didn't find anything in that regards either.

Just that one SS on claiming to outperformed sukhois engine turbine blade and vanes. Which I had shared already. Nothing available in public wheather those dmrl made al31 blades & veins were tested it al31 (inflight as well) Or not.

So yeah here we're without much available we can just speculate.

Anyways expect good progress as this dms4 were developed in 2013 since then alot of iterative progress would have had happened.

And for jv I think posts sum up why

Why drdo desires jv i have no idea most likely mistrust of the policy makers in them. Lack of confidence of babus in drdo. few years back they were facing issues with small nirbhay cruise missile engine.

Unfortunately , at the moment it seems like that . Moreover with the kind of perverse no risk strategy pursued by the MoD babooos , any slight setback in the program were it to be run indigenously will immediately see a cessation of funds .

Hence the thinking within the DRDO establishment must be - why risk it ? Go in for a JV , run the program in parallel with the meagre funds at their disposal & get all those tech which DRDO is unable to realise due to a paucity of funds thru the JV.

This thinking is also the result of what I've pointed out in a post on the Economy sub forum wherein a majority of these babooos are of a non technical background.

Last edited: