- Joined

- Jul 1, 2024

- Messages

- 853

- Likes

- 3,974

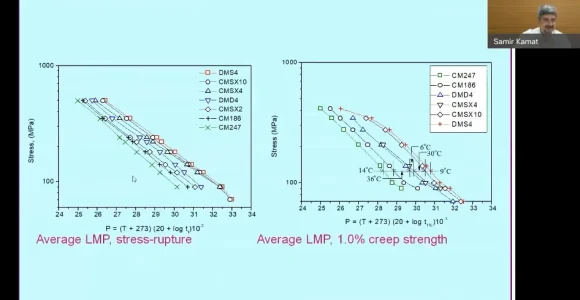

Generally I don't believe in this crap, I still don't, but the folks in BRF are thinking that there's a secret 90KN dry thrust derivative of Kaveri??

View: https://youtu.be/dhXNb-W76I8?si=EkIKzLiseBE3u1_B

This is what one of the BRF members "habal" has said & I quote

" this is a different engine, 140 kn max thrust is targeted and whether it achieved that or not is not clear but 102 kn dry thrust was achieved in russia high altitude tests while engine dry thrust target was previously at 90 kn. From my open source reading this engine is not kaveri without afterburner called KDE but another varient rated for 90 kn which exceeded expectations during russian high altitude tests. Some sources have given this name as ganga which is an engine developed for AMCA.

This also clarifies a flurry of Kaveri 2.0 news recently while everyone was left wondering why Kaveri 2.0 was being discussed while KDE without afterburner was still work in progress with two samples delivered by Godrej"[/URL]

I don't think so this would be happening or kind of kept kept secret but some how got leaked.

But that thing isnt impossible either if we had to do and project would have e been initiated on our own.

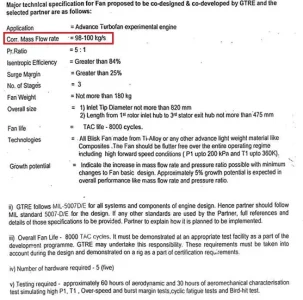

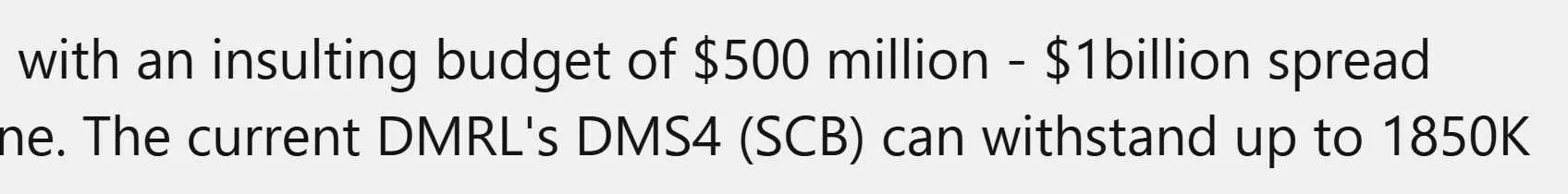

DMS4 for SCBs & vanes developed in 2012 which could sustain Tet of 1550-1600c easily(our cmsx equivalent, 3rd gen) and add to that new development happened since because they won't have been sitting idle for this many years. Dms3 was developed in 2004 which had 8c more tet than cmsx4 (2nd gen).

I won't be suprised they would have developed DMS5 either. And even huge development have happened in regards with Thermal barrier coatings in last 10year many things have changed we can sustain a scramjets the TBCs which go in there are the latest ones ..I suppose this techs build over could sustain Tet upto 1700-1800c.we have many technologies already developed to roll out a f119 class turbofan. various alloys are developed in order to reduce weights(carbon polymer) of kaveri. We have not suffered on metalurgical front in kaveri instead there were issues like unstable combustion in afterburner, vibrations screech flutter which are solved we took help of snecma. The thing left is to prove in the newer afterburner made by brahmos which design is supposed to sort out that flutter issue. If that's done we can roll out f119 class engines it's tet is 1650c.

Read my recent post on this threads or more info.

The another missing piece is the manufacturing capacity which we have(al31) but lack advance process for coating deposition (ebpvd) and they aspires to seek even other modern manufacturing processes.

Via f414 deal again refer my post on this and previous page for more info.

We can't scale up our ebpvd developed by RCI to large extend limited only upto helicopter blades used by DMRL.

You're too underestimating hal mate. Ends user agreements are limiting hal from using indigeneous materials for single crystals blades as per contract alloys must come from russia it is not like they don't have the capacity.

They have the capability to produce & use indigeneous SCBs in al31. DMRL has developed SCBs for al31fp. they had developed dms4 nickel based super alloy SCBs,turbine vanes for al31. Initially dms3 was developed but there were some deficiencies which were sorted out and even further improvements lead to dms4 and who actually dmrl went to for this hal koraput. hal used dmrl developed thermal barrier coatings to improve al31 without compromising the agreement Clause. It eventually improved the al31. Not just that the nozzle mtbo was also improved by dmrl. Hal has the capability to manufacture modern SCB.

Just a mere fact kaveri has higher tet than al31.

Without ds blades and indigeneous TBCs. The ds blades used in kaveri provides 1050c tolerance along with other means like tbc & cooling it is then improved upto 1450c. Al 31 tet is below 1400c. The f110 mid iteration has tet of 1510c. M88 has 1577c, the f119 has 1650c,F135 has 1960c, Al41 has 1640c, f414epe has 1600c, ej200 1535c notice super cruising engines have tet above/around 1550c

The kaveri now uses dmd4 a directionaly solidified which shares materials with dms4.

Why doesn't they use dms4 ? Who knows maybe dmd4 does the job. after it surely provides tet higher than 1450c tet without latest TBCs available here. Tet was never an issue in kaveri. Given the development we have done in tbc with dms4 kaveri can achieve tet of 1700c easily.

TBCs developments are quite unreported given the developments we have done for hstdv. I will say kaveri can achieve tet of 1700c+. But that would require work staring from very begging and would cost abit. Maybe even major redesigning as kaveri was designed with ds blades. And we don't even have e test facilities yet so again we can't there are tens of reason for it. Even the new fan paired with this new technologies we can develop 5th gen engine today (given infrastructure is approved)

But before that kaveri has to prove itself & the kde too Unless & untill mod babus will not allot funds

It is such a shame we're Just allocating 23k crores for drdo. Mod babus don't understand anything unless and until kaveri is proved no funds till then. That's the reality. Kaveri isn't facing materials problem it just can't initiate new programs and it will have to prove 90s design first to get funds after that they would be making a true low bypass engine with recent techs developed.

Visit pg no 29 of this thread handle named shiro on twitter has provided good info.

There is reason why samir v kamat said we can make 5th gen AMCA engine on our own. Chasing jv could be the reason of no confidence in them from babus system politicians and also drdo desired carbon composites tech along with adaptive cycle.

View: https://twitter.com/ShiroBarks/status/1899837650384863653?ref_src=twsrc%5Etfw%7Ctwcamp%5Etweetembed%7Ctwterm%5E1899837650384863653%7Ctwgr%5E%7Ctwcon%5Es1_c10&ref_url=

While with f414 new infrastructure will be brought improving overall manufacturing capability.

View attachment 29697

However this are not used in the al31 i suppose they should have had renegotiated it. Or maybe in the process.

Bel has no job here.

Godrej, midhani , l&t, bharat forge, azad engineering can contribute but they only want to manufacture things while without spending on r&d. This doesn't apply to midhani though they have done descent job.

From ddr