Any links detailing same?Not for engine development

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GTRE GTX 35VS Kaveri (14 Viewers)

- Thread starter Kattar

- Start date

More options

Who Replied?- Joined

- Jun 27, 2024

- Messages

- 4,318

- Likes

- 25,277

- Joined

- Jan 5, 2025

- Messages

- 153

- Likes

- 694

We what do we have to pay for this year.

Lca mk1a jets that will be produced.

Lcamk2 prototype.

AMCA prototype work.

Su30mki upgrade program.

That money will go for above jets and engines.

24k crore is going for naval fleet. Most probably initial payment for naval rafale M.

- Joined

- Jul 7, 2024

- Messages

- 279

- Likes

- 2,156

GTRE Director - 18:40 onwards

View: https://www.youtube.com/watch?v=a4OIUB1GCMg

- Unsuccessfully "begging" people to get timeslots for the high-altitude test beds and flying test beds, probably in Russia.

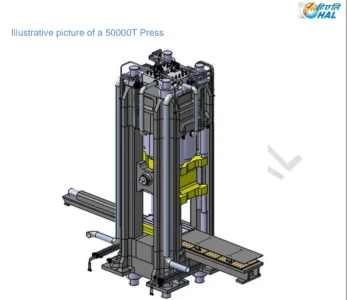

- No 50K hydraulic press.

- Only spent $250 million when 10 times the amount is needed - $2.5 billion.

- URGENTLY NEEDED - A coordinated national mission for aero-engines involving all stakeholders(and that probably would mean IAF not just sitting and ordering fighters and aero-engines like biryani in a restaurant. They need to be more proactively involved in making said biryani - maybe even earmarking part of their funds for R&D; exactly like responsible forces like USAF and USN do)

- Need for more skilled manpower. He implies a 'Dutch Disease' phenomenon in India, where graduates are going to IT instead of deep tech in MTech.

It's happening boys.

View: https://x.com/alpha_defense/status/1885921894270165443

Last edited:

- Joined

- Jun 27, 2024

- Messages

- 378

- Likes

- 2,076

Manufacturer?

- Joined

- Jul 1, 2024

- Messages

- 4,793

- Likes

- 25,171

Manufacturer?

The world's largest hydraulic presses | Gasparini Industries

[...]Read More... from The world’s largest hydraulic presses

www.gasparini.com

www.gasparini.com

- Joined

- Jul 1, 2024

- Messages

- 4,793

- Likes

- 25,171

View: https://www.youtube.com/live/fIsE84Cke5Y?si=tW9zOtuz4Jdgz8z0

This is a 3 hour + program on the present & future of the Indian Aero Engine program & ecosystem. From what I understand all answers on the Kaveri & any & every derivative engine of the Kaveri is also in it including plans for a 90 KN KED to power the LCA Mk-1a

during the MLU , it's testing protocol , time taken , etc except I haven't the time & patience to go thru it & summarise the points.

If any body out here is considerate enough to do it , please list out the necessary points for the benefit of the entire forum.

I thought an Indian Mfg company would have taken the challenge - given it was MECO giving consultancy.

The world's largest hydraulic presses | Gasparini Industries

[...]Read More... from The world’s largest hydraulic presseswww.gasparini.com

- Joined

- Jun 27, 2024

- Messages

- 1,610

- Likes

- 7,710

Indian companies cannot manufacture above 10k ton and that too after TOT.I thought an Indian Mfg company would have taken the challenge - given it was MECO giving consultancy.

This is where Our PSUs and so called IITs, NITs, top private college failed.

- Joined

- Jul 1, 2024

- Messages

- 4,793

- Likes

- 25,171

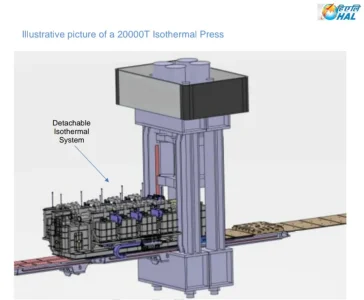

What's the maximum capacity hydraulic forging press we've installed in India ? If I'm not mistaken HAL has one & it's ~ 20, 000 tons capacity or less.I thought an Indian Mfg company would have taken the challenge - given it was MECO giving consultancy.

Ideally we should be taking a leaf out of China & get a local company involved in a partnership for them to derive learning & for usual preventive & defective maintenance.

- Joined

- Jun 27, 2024

- Messages

- 1,610

- Likes

- 7,710

Last time I enquired jindal steel imported most of its equipment from Japan Machine Work and other such japanese firms. Forge as low as 2500 ton was imported.

That is too be expected from a man that said we are not looking into R&D this decade.

It's pathetic really.

That is too be expected from a man that said we are not looking into R&D this decade.

It's pathetic really.

Exactly I would have liked L&T, Kalyani and BHEL to form consortium in manufacturing heavy forging press. L&T has 10T press. I am surprised given India is one of the largest producer of steel and also has large sources of iron ore - we should have invested long ago in R&D of heavy forgings. We seriously lack investment in making big furnaces anyway for steel sector. So Drills, Forgings, Furnaces is something we should be building capacity here.What's the maximum capacity hydraulic forging press we've installed in India ? If I'm not mistaken HAL has one & it's ~ 20, 000 tons capacity or less.

Ideally we should be taking a leaf out of China & get a local company involved in a partnership for them to derive learning & for usual preventive & defective maintenance.

- Joined

- Jun 27, 2024

- Messages

- 1,610

- Likes

- 7,710

Not their own.L&T has 10T press

L&T has its own hydraulic division but they supply peripheral components of hydraulic systems like crane. I'm sure they can manufacture 10000 to 25000 ton press if they try but market dynamics does not suit it.

You see most indian companies are able to manufacture below 1000 ton because market dynamics Suit it. There are several industries that employ 100 to 250 ton press across gujarat like die makers, knock off automobile component's, sanitary.

I have posted about these companies in Promising startup and companies thread.

When it comes to super heavy presses we are missing the local market for its demand: shipbuilding, aerospace, heavy machinery, composites, automobile.

That is why we import 1.26 million tons of special grade steel component's from Choina which are most likely formed in heavy press.

Indian firms find it easier to import 5k 10 k press than to invests in building their own.

Maybe give tax breaks in form of money invested in r&d in particular sectors directed by Gorminy can do the trick.

- Joined

- Feb 5, 2025

- Messages

- 1,014

- Likes

- 4,384

- Joined

- Jun 27, 2024

- Messages

- 378

- Likes

- 2,076

I thought an Indian Mfg company would have taken the challenge - given it was MECO giving consultancy.

Indian companies cannot manufacture above 10k ton and that too after TOT.

This is where Our PSUs and so called IITs, NITs, top private college failed.

There are many Indian companies which have been designing, making and exporting presses of over 20k tonnes.Last time I enquired jindal steel imported most of its equipment from Japan Machine Work and other such japanese firms. Forge as low as 2500 ton was imported.

That is too be expected from a man that said we are not looking into R&D this decade.

It's pathetic really.

I was related to one of them once so won't site names here.

A bit or orders and R&D budget would be enough to breach 50k tonnes capacity in a short time.

- Joined

- Jun 27, 2024

- Messages

- 1,610

- Likes

- 7,710

Movie chinese posts to their economy thread.

I don't see any reason why a discussion about chinese forges should go on in Kaveri thread.

I haven't found any 5k ton+ press in public domain so far.

I don't see any reason why a discussion about chinese forges should go on in Kaveri thread.

Can you name drop the one which is unrelated to you.There are many Indian companies which have been designing, making and exporting presses of over 20k tonnes.

I was related to one of them once so won't site names here.

A bit or orders and R&D budget would be enough to breach 50k tonnes capacity in a short time.

I haven't found any 5k ton+ press in public domain so far.

- Joined

- Jun 30, 2024

- Messages

- 135

- Likes

- 952

View: https://www.youtube.com/live/fIsE84Cke5Y?si=tW9zOtuz4Jdgz8z0

This is a 3 hour + program on the present & future of the Indian Aero Engine program & ecosystem. From what I understand all answers on the Kaveri & any & every derivative engine of the Kaveri is also in it including plans for a 90 KN KED to power the LCA Mk-1a

during the MLU , it's testing protocol , time taken , etc except I haven't the time & patience to go thru it & summarise the points.

If any body out here is considerate enough to do it , please list out the necessary points for the benefit of the entire forum.

Keynote speech by Vice-Admiral was meant to be delivered by CDS but he was called to MOD for a unscheduled meeting, hence Vice-Admiral reading it out. So content of the speech reflects thinking at highest levels in Uniformed class. I've tried to summarize the lengthy word salad with my interpretations below (I remember hearing better speeches at school debate competitions)

# Upto 12MW Diesel Engines can be made for upto 2000T displacement ships by local Chaapris looking to earn two meals a day in Rupees

# We are happy to source Gas Turbines for ships from US & Ukraine and very happy that Zorya is setting up Overhauling facilities in India so all of us can do Aatmanirbhar dance once in a while. Kaveri marine engine does not exist and hence shall not be spoken of on stage.

# Indigenous Aero Engines are aspirational (Ooooh, who knew?). Kaveri has faced many setbacks but dry version is being stuffed down our throats. It has now cleared all ground tests and is cleared for Flying Tests. It will (may?) power Ghatak. (My interpretation - End of story for Kaveri. Decision makers are happy that MOD has something to show for the chillar Rupees they had to throw at DRDO & GTRE for over 3 decades and can now bury the Kaveri for good before it threatens import gravy train like the LCA has done)

# Development of Aero Engines is very complex ( and therefore this largest nation on earth with 3rd largest economy (soon) whose engineers are in demand world over must be subservient to goras and beg them) for a joint venture so as make local name plate version of their latest and greatest creation (for which we can thankfully pay in dollars and euros and in worst case Rubles so that kith and kin of our beloved MOD babus and top-offi-class may continue to get scholarships and cushy jobs in thunk tanks for few decades more)

In short, CDS rep took stage at India's only Aero Show's seminar on Aero Engine manufacturing to inform us that JV is the only way forward for Aero & Marine Jet Engines if forced to wave the AatmaNirbhar fig leaf (instead of direct imports)

Yet to see rest of the seminar for what poor DRDO folks are m*st*rb*ting to currently. Will update if I manage to do that

Last edited:

- Joined

- Jul 5, 2024

- Messages

- 689

- Likes

- 3,183

No really here Government special purpose support team is needed because once these heavy setups are done then they will get benefits for decades.Not their own.

L&T has its own hydraulic division but they supply peripheral components of hydraulic systems like crane. I'm sure they can manufacture 10000 to 25000 ton press if they try but market dynamics does not suit it.

You see most indian companies are able to manufacture below 1000 ton because market dynamics Suit it. There are several industries that employ 100 to 250 ton press across gujarat like die makers, knock off automobile component's, sanitary.

I have posted about these companies in Promising startup and companies thread.

When it comes to super heavy presses we are missing the local market for its demand: shipbuilding, aerospace, heavy machinery, composites, automobile.

That is why we import 1.26 million tons of special grade steel component's from Choina which are most likely formed in heavy press.

Indian firms find it easier to import 5k 10 k press than to invests in building their own.

Maybe give tax breaks in form of money invested in r&d in particular sectors directed by Gorminy can do the trick.

If somebody doubt it?! Ask usa, russia.

So, here I must say government direct intervention is needed.

- Joined

- Jun 30, 2024

- Messages

- 135

- Likes

- 952

Very good speech by DRDO scientist - Dr. Subrata Das . He didn't go into specifics and that maybe deliberateKeynote speech by Vice-Admiral was meant to be delivered by CDS but he was called to MOD for a unscheduled meeting, hence Vice-Admiral reading it out. So content of the speech reflects thinking at highest levels in Uniformed class. I've tried to summarize the lengthy word salad with my interpretations below (I remember hearing better speeches at school debate competitions)

# Upto 12MW Diesel Engines can be made for upto 2000T displacement ships by local Chaapris looking to earn two meals a day in Rupees

# We are happy to source Gas Turbines for ships from US & Ukraine and very happy that Zorya is setting up Overhauling facilities in India so all of us can do Aatmanirbhar dance once in a while. Kaveri marine engine does not exist and hence shall not be spoken of on stage.

# Indigenous Aero Engines are aspirational (Ooooh, who knew?). Kaveri has faced many setbacks but dry version is being stuffed down our throats. It has now cleared all ground tests and is cleared for Flying Tests. It will (may?) power Ghatak. (My interpretation - End of story for Kaveri. Decision makers are happy that MOD has something to show for the chillar Rupees they had to throw at DRDO & GTRE for over 3 decades and can now bury the Kaveri for good before it threatens import gravy train like the LCA has done)

# Development of Aero Engines is very complex ( and therefore this largest nation on earth with 3rd largest economy (soon) whose engineers are in demand world over must be subservient to goras and beg them) for a joint venture so as make local name plate version of their latest and greatest creation (for which we can thankfully pay in dollars and euros and in worst case Rubles so that kith and kin of our beloved MOD babus and top-offi-class may continue to get scholarships and cushy jobs in thunk tanks for few decades more)

In short, CDS rep took stage at India's only Aero Show's seminar on Aero Engine manufacturing to inform us that JV is the only way forward for Aero & Marine Jet Engines if forced to wave the AatmaNirbhar fig leaf (instead of direct imports)

Yet to see rest of the seminar for what poor DRDO folks are m*st*rb*ting to currently. Will update if I manage to do that

# Four categories related to Engine Development- 1. Design & Technology. 2. Material & Manufacturing. 3. Quality, Reliability, Certifications, Life cycle testing etc. 4th is LRUs related to engine

# Breakdown of development cost - 40% Material, 30-35%, Manufacturing, 20-25% Sub-systems / LRUs

# When people talk of TOT, CKD, SKU, it only covers above 3. Nobody gives Design & Technology

# When Kaveri program started nothing was available - Design Tools, simulation or analysis tools, Material Characteristics Data. All had to be developed independently

# None of engine producers in country who have got so called ToT have got competence in the Design & Technology. It is available to the country now only because of Kaveri program (In short, they are doing screw-driver-giri only and have no autonomy)

# We’ve developed 35-40 material & manufacturers across country through Kaveri program.

# We now have 80-85% of required capability for Aero Engines locally i.e except in one or two areas

# Indian Engine will be on a Indian Aircraft in application role in two years

# We have some deficiencies in test facilities which has been presented in detail in many forums in many ways. So won’t speak of that here

# At GTRE. we have 5 test beds and all 5 are occupied 365 days a year. Two additional test beds for upto 130 KN coming up near Bengaluru

# When we have to integrate we got stuck although it is only 20% value., we had to go reverse engineer everything including lubricants, fuel systems etc

# All systems have gone through all sorts of test and certifications and will be seen flying in couple of years as we have ensured reliability & quality

# Contemporary Technologies such as BLISK, BLINK & Thrust Vectoring should be aimed for now. This needs co-ordination and integrated planning between Design agency like DRDO, certification agencies, user & industry. Unless this is done, we cannot be truly atmanirbhaar in Aero engines for next 20-30 years

Last edited:

- Joined

- Jun 30, 2024

- Messages

- 135

- Likes

- 952

Very good speech by DRDO scientist - Dr. Subrata Das . He didn't go into specifics and that maybe deliberate

# Four categories related to Engine Development- 1. Design & Technology. 2. Material & Manufacturing. 3. Quality, Reliability, Certifications, Life cycle testing etc. 4th is LRUs related to engine

# Breakdown of development cost - 40% Material, 30-35%, Manufacturing, 20-25% Sub-systems / LRUs

# When people talk of TOT, CKD, SKU, it only covers above 3. Nobody gives Design & Technology

# When Kaveri program started nothing was available - Design Tools, simulation or analysis tools, Material Characteristics Data. All had to be developed independently

# None of engine producers in country who have got so called ToT have got competence in the Design & Technology. It is available to the country now only because of Kaveri program (In short, they are doing screw-driver-giri only and have no autonomy)

# We’ve developed 35-40 material & manufacturers across country through Kaveri program.

# We now have 80-85% of required capability for Aero Engines locally i.e except in one or two areas

# Indian Engine will be on a Indian Aircraft in application role in two years

# We have some deficiencies in test facilities which has been presented in detail in many forums in many ways. So won’t speak of that here

# At GTRE. we have 5 test beds and all 5 are occupied 365 days a year. Two additional test beds for upto 130 KN coming up near Bengaluru

# When we have to integrate we got stuck although it is only 20% value., we had to go reverse engineer everything including lubricants, fuel systems etc

# All systems have gone through all sorts of test and certifications and will be seen flying in couple of years as we have ensured reliability & quality

# Contemporary Technologies such as BLISK, BLINK & Thrust Vectoring should be aimed for now. This needs co-ordination and integrated planning between Design agency like DRDO, certification agencies, user & industry. Unless this is done, we cannot be truly atmanirbhaar in Aero engines for next 20-30 years

Dr. Subrata Das clarifies that only plan now if for Kaveri Dry Thrust. Kaveri will not be integrated with LCA. GTRE has submitted plan for High thrust engine for AMCA but is upto GoI

GTRE is trying to help develop Indian companies with manufacturing high end components such as Turbines etc as agencies like HAL have faced issues despite receiving so called ToT

Users who are viewing this thread

Total: 11 (members: 0, guests: 11)

Latest Replies

-

Indian Special Forces

- COLDHEARTED AVIATOR

-

Indian Economy

- swesh

-

Islamic Extremism in India: News, Discussions & Updates.

- Hindaviswarajya

-

Police/CAPF Special Units Discussion

- Unknowncommando

-

Operation Sindoor & Aftermath

- Nishaanbaaz

-

Indian Small Arms & Weapons

- johny_baba

-

Indo-Tibetan Border Police (ITBP)

- Unknowncommando

-

-

Air India AI 171 Crash in Ahmedabad

- Interested

-

Chess: Global Updates

- Yuyutsu