You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese Economy Watch (8 Viewers)

- Thread starter rockdog

- Start date

More options

Who Replied?- Joined

- Jul 3, 2024

- Messages

- 747

- Likes

- 361

India has already done this,Yeah, he didn’t need to get emotional. Also it’s probably better to just buy from a different country instead of complaining.

India's largest source of TBM imports is China

- Joined

- Jul 3, 2024

- Messages

- 747

- Likes

- 361

China's tunnel boring machine industry achieves leapfrog development

By Li Xinping (People's Daily) 14:39, May 10, 2024A tunnel boring machine (TBM), also referred to as full-section tunnel boring machine, is a machine used to excavate tunnels. It combines multiple technologies such as machinery, electronics, information technology, and artificial intelligence, being acclaimed as the "king of construction machinery."

More than two decades ago, China did not have its own TBM. Today, Chinese-produced TBMs account for nearly 70 percent of the global market.

An ultra-large diameter tunnel boring machine (TBM) rolls off the production line in Changsha, central China's Hunan province, February 26, 2024. (People's Daily Online/Li Jian)

How did the Chinese TBMs make this giant leap? People's Daily reporters delved into the TBM manufacturing companies to uncover the secrets.

In early 2000, when China Railway Group Limited (hereafter referred to as China Railway) decided to develop its own TBM, some thought it was an unrealistic idea.

Wang Dujuan, chief engineer of China Railway Hi-Tech Industry Corporation Limited (CRHIC), a subsidiary of China Railway, said that a TBM has over 20,000 components, and its control system alone has more than 2,000 control points. "Many colleagues at that time had never even seen a TBM before," she recalled.

Thanks to substantial efforts and investments, China's first domestically developed earth pressure balance TBM with independent intellectual property rights made its debut in 2008, known as the "China Railway No. 1" TBM.

On February 6, 2009, the China Railway No. 1 TBM started working for a metro project in north China's Tianjin municipality. Four months later, a tunnel of the Tianjin Metro Line 3 was holed through, with ground settlement carefully controlled within 3 millimeters and passing all expert inspections.

Since then, the Chinese TBM industry has gained momentum, with a number of competitive manufacturers emerging and growing, such as China Railway Engineering Equipment Group Co., Ltd. (CREG), China Railway Construction Heavy Industry Corporation Limited (CRCHI), and CCCC Tianhe Mechanical Equipment Manufacturing Co., Ltd. affiliated with China Communications Construction Company Limited (CCCC).

Today, China boasts the world's largest TBM fleet, with approximately 5,000 units. Over 90 percent of China's metro tunnels were constructed using TBM technology.

A TBM stands several stories high and is as heavy as hundreds of elephants. It consists of tens of thousands of components. To enhance the resilience of the industrial and supply chains, every link of the industry must collaborate effectively.

"China's TBM industry follows a development path where the manufacturing of complete TBMs drives the manufacturing of components," said Zhang Zhiguo, general manager of CREG.

Ten years ago, bearings and gearboxes needed to be imported due to weaknesses in the industrial chain, and today, these weaknesses are gradually being resolved, Zhang told People's Daily.

Crafting main bearings proved to be one of the most challenging tasks due to the extreme and harsh operating conditions they face as the "heart" of a TBM, including ultra-heavy loads, large eccentric loads, and frequently varying loads. Besides, they need to meet critical standards such as high reliability and long service life. The material selection, design, manufacturing, and testing of them also presented immense difficulties. That's why they are considered the pinnacle of the industrial chain of large-scale, high-end, precision bearings.

An ultra-large diameter tunnel boring machine (TBM) is assembled at a production base of China Railway Engineering Equipment Group Co., Ltd. (CREG) in Hangzhou, east China's Zhejiang province. (People's Daily Online/Long Wei)

To finalize the design for main bearings, the Chinese research and development team experimented with hundreds of materials and processes, conducted thousands of theoretical verifications and design optimizations, and analyzed tens of thousands of inspection and test data sets.

In collaboration with leading specialty steel companies in China, CRCHI conducted in-depth research on material elemental matching and methods for controlling impurities and carbides, ultimately overcoming the bottleneck in the materials used for main bearings.

On October 12, 2023, a TBM main bearing with a diameter of 8.61 meters rolled off the production line at a CRCHI facility in Changsha, central China's Hunan province. It was the world's largest-diameter main bearing for TBM, boasting the heaviest weight and highest bearing capacity.

"It marked that China has become a global leader in the development and manufacturing of ultra-large diameter main bearings. Chinese-produced TBM main bearings now cover the full range from small to ultra-large diameters," said Liu Feixiang, chief scientist of CRCHI.

Additionally, Chinese enterprises are consistently moving towards intelligent and automated TBM operations, exploring autonomous excavation and remote control capabilities.

For instance, China's independently developed TBM "Linghang" is equipped with a system to monitor the status of key components in real-time, including the wear and temperature of cutting tools and slurry circulation pipes. It also provides damage predictions, effectively improving the construction efficiency.

The "Linghang" TBM also provides functions of intelligent excavation, intelligent assembly, advanced geological forecasting, and tail-end seal safety warnings. Therefore, it can automatically adjust parameters and excavate in ordinary geological conditions and can be controlled remotely from the ground surface under special circumstances.

Chinese TBM manufacturers are continuously expanding into overseas markets.

In 2012, China exported its first domestically produced TBM after China Railway won the bid for a metro construction project in Kuala Lumpur, Malaysia. During the construction, the "China Railway No. 50" TBM erected an average of eight rings per day, achieving over ten rings per day for seven consecutive days, setting a new record for metro TBM tunneling in Malaysia.

In 2015, China's "Zhang Heng" and "Zhan Tianyou" TBMs won contracts for metro projects in Singapore. In 2016, a rectangular pipe jack TBM was awarded another contract, pioneering the entry of China's specialized TBMs into overseas markets.

In 2019, the "China Railway No. 699" TBM won a bid for a railway project in northern Italy, marking the first application of China's advanced tunneling equipment in a country of European Union. In the same year, two domestically produced TBMs were contracted for a Paris metro construction project in France.

"All these demonstrate the recognition for the comprehensive strength of China's TBM brands by the international high-end market," said Zhang.

Don’t worry

- Joined

- Jul 3, 2024

- Messages

- 747

- Likes

- 361

On October 31, a super-large diameter shield machine with a maximum excavation diameter of 16.64 meters rolled off the production line in Changsha. It will be used for the construction of the world's longest underwater highway tunnel—the Haitai Yangtze River Tunnel. The head of China Railway Construction Heavy Industry Group stated that this is the largest diameter shield machine independently developed in China to date, marking a new breakthrough in the research and industrialization of domestically produced super-large diameter shield machines.

This shield machine is named "Jianghai," jointly built by China Railway Construction Heavy Industry Group and China Railway 14th Bureau Group. The entire machine is approximately 145 meters long and weighs about 5,000 tons. The cutter head of "Jianghai" is painted with a blue wave pattern, symbolizing access to rivers and seas.

The Haitai Yangtze River Tunnel is located in the estuary area of the Yangtze River in Jiangsu Province, starting from Haimen District in Nantong and ending in Taicang City, Suzhou. The total length of the project is 39.07 kilometers, with the underwater tunnel measuring 11.185 kilometers. Among them, the shield tunnel section is 9,315 meters long, and the route needs to pass through complex geological zones such as silty clay and fine sandy composite strata, characterized by ultra-long distance, ultra-large diameter, ultra-high water pressure, ultra-deep burial, and complex working conditions.

"When the shield machine crosses the Yangtze River and the levees on both sides, the settlement must be controlled within 1 centimeter, making construction very challenging," said Song Huan, a senior engineer for the Haitai Yangtze River Tunnel project at China Railway 14th Bureau. The geological exploration in the river is limited, and there are many uncontrollable factors. Completing ultra-long-distance tunneling in the complex environment at the riverbed is akin to "crossing the river by feeling the stones."

The research and development team spent over two years tackling key components such as the cutter head, tools, and main drive, implementing targeted designs. The entire machine adopts multiple new technologies developed independently. Fan Ruiqiang, a senior engineer at the tunneling machine research and design institute of China Railway Construction Heavy Industry Group, explained that a super-large diameter means a heavy load on the main drive bearing. Therefore, the main drive is equipped with telescopic functions and monitoring systems to effectively avoid overload of the main bearing caused by abnormal forces on the cutter head. At a maximum burial depth of 75 meters and under ultra-high water pressure of 7.5 bar, the cutter head is configured with a normal pressure tool-changing function, with tools having higher hardness and better wear resistance. An intelligent assembly system for segment connection components enhances the pressure-bearing capacity of sealing components, and the fourth-generation synchronous double-liquid grouting technology achieves millimeter-level precision control of tunnel settlement, ensuring efficient and safe construction.

- Joined

- Jul 3, 2024

- Messages

- 1,573

- Likes

- 2,193

- Joined

- Jul 1, 2024

- Messages

- 1,703

- Likes

- 6,452

India has already done this,

India's largest source of TBM imports is China

Don't worry. All China did was to ensure that India would seek its own domestic version. You brethren quite bungled up which was a sweet gig, manufacturing TBMs to the largest market. Now that will be gone and India will become your competitor.

- Joined

- Jul 3, 2024

- Messages

- 747

- Likes

- 361

Don't worry. All China did was to ensure that India would seek its own domestic version. You brethren quite bungled up which was a sweet gig, manufacturing TBMs to the largest market. Now that will be gone and India will become your competitor.

This is the right path

China has come the same way.

--------------------

On October 28, the "Jianghan Pioneer" hard rock tunneling machine developed by China Railway Industry’s China Railway Engineering Equipment Group Co., Ltd. was successfully launched. It has a maximum excavation diameter of 12.23 meters, a total length of approximately 227 meters, a total weight of about 3000 tons, and a total excavation length of about 12.17 kilometers, making it a leader among similar equipment in the country.

The success of this "big guy" is attributed to Chief Engineer Jia Lianhui and his team at China Railway Engineering Equipment Group Co., Ltd. Over the course of 10 years, they completed the development process that took foreign teams four to five decades, constantly breaking records in the field of tunnel boring machines and earning global recognition and respect for "Made in China."

Recently, Jia Lianhui shared with a Science and Technology Daily reporter the arduous journey he and his team undertook to achieve the development of domestic tunnel boring machines from scratch and then to excellence.

"Without mastering key technologies, there is no voice."

Reporter: What is a tunnel boring machine?

Jia Lianhui: A tunnel boring machine is a mechanical device used for excavating tunnels. It uses rotating cutting tools to cut through rock layers while simultaneously performing crushing, mucking, and supporting operations, allowing for continuous advancement and forming tunnel cross-sections. Tunnel boring machines are characterized by high efficiency, safety, and economy, and are widely used in tunnel construction, subway construction, and other projects.

In China, machines used for soft soil layers are commonly referred to as shield machines, while those used for rock layers are called hard rock tunneling machines. The industry believes that shield machines are one of the significant pieces of equipment for measuring a country's manufacturing level and capabilities.

Reporter: Why did the company decide to independently develop shield machines in 2001?

Jia Lianhui: In the 20th century, shield machines used in major projects in China relied on imports. In 1997, to accelerate the construction progress of the Qinling Tunnel on the Xikang Railway, relevant departments purchased German shield machines, significantly improving tunnel excavation efficiency. However, this equipment was extremely expensive, leading to a substantial increase in construction costs. Moreover, the core technology was not in our hands, making us relatively passive in equipment maintenance and updates.

Without mastering key technologies, there is no voice. Since then, the dream of creating our own shield machines has become our team's goal.

Reporter: What difficulties did you and your team overcome while developing the first shield machine?

Jia Lianhui: Developing a shield machine involves dozens of technical fields, including mechanics, hydraulics, and electrical engineering, with over ten thousand components. Foreign companies implemented technological blockades, and we had no equipment blueprints, nor did we know the key performance indicators, starting from scratch made it incredibly challenging.

After the project was launched, the first thing we did was to search for "foreign shield machines." Some team members researched data, while others conducted field investigations. After some time, we initially grasped the performance and structure of shield machines, laying the groundwork for subsequent development work.

Reporter: Which part of the R&D process was the most challenging to break through?

Jia Lianhui: At that time, there was no complete production system for shield machines in our country; we had to develop each of the thousands of components one by one. Each component required design, testing, and repeated verification, which was a massive workload. The team was not only developing the shield machine but also building a brand-new production platform for our country.

To speed up the development process, our team collaborated with Zhejiang University and other universities, as well as upstream and downstream industry chain units, to tackle thousands of technical challenges in areas such as thrust load-sensitive control and closed-loop constant power control systems.

After developing a prototype, we began testing its performance at multiple construction sites while adjusting the prototype's performance according to production needs. In 2007, underwater 30 meters in the Yangtze River in Wuhan, our team risked their lives to enter the chamber under pressure. Previously, foreign experts dared to enter with a maximum pressure of 3 kilograms, while we entered with 4.7 kilograms, venturing into the life-threatening zone of shield construction and obtaining crucial technical data.

At the construction site of the Yinda Jihuang project at an altitude of over 3700 meters, an imported shield machine got stuck in the tunnel due to design defects. Our team risked the danger of a potential collapse, repeatedly entering a tunnel about 1 meter in diameter to check geological conditions and develop a "deblocking" plan for the shield machine.

During that difficult time, we accumulated rich technical data and mastered the key technologies for shield machines.

Reporter: When was the independently developed shield machine launched?

Jia Lianhui: In 2008, China’s first composite earth pressure balance shield machine with independent intellectual property rights, "China Railway No. 1," was officially launched in Xinxiang, Henan Province, breaking the monopoly of "foreign shields" and achieving a breakthrough of "from 0 to 1" for domestic composite shield machines.

"China Railway No. 1" was entirely designed and manufactured by us, with all technical indicators and performance reaching the international advanced level at the time, including tunneling speed and construction accuracy. In 2009, "China Railway No. 1" made its debut in the Tianjin Metro Line 3 project, successfully passing under historical buildings such as Zhang Xueliang's former residence and the Porcelain House, with ground subsidence controlled within 3 millimeters.

"Let our shield machines go abroad and gain world recognition."

Reporter: Has the independently developed shield machine showcased its capabilities in domestic projects, and is it going overseas?

Jia Lianhui: Before 2012, overseas clients did not trust "Made in China." A representative from a Malaysian company bluntly stated, "You do well in China, but you have no overseas application experience; I am very worried about you." After more than ten in-depth communications, this Malaysian client signed an order for two shield machines. This was the first overseas order our company received. Ultimately, Chinese shield machines achieved a new record in Malaysia with excellent performance, tunneling up to 21 meters per day and completing the project 43 days ahead of schedule.

Reporter: In 2020, you participated in the development of the world's largest diameter hard rock tunneling machine. Is the development difficulty greater than that of shield machines?

Jia Lianhui: Yes. Shield machines work with soft rock and gravel, suitable for urban subways, highway tunnels, and municipal pipeline projects at depths below 30 meters. Hard rock tunneling machines work with granite and marble, suitable for long-distance tunnels and hydropower station water diversion tunnels at depths of several hundred to thousands of meters.

Reporter: Why did the company initiate this R&D project at that time?

Jia Lianhui: Our team's long-standing wish has been to let our shield machines go abroad and gain world recognition. In 2020, the company participated in the Belt and Road project — the construction of the highway tunnel from Kovezheti to Kobi in Georgia's North-South Corridor. Once completed, the highway tunnel will alleviate traffic congestion and winter road disruptions in the area. To enhance construction efficiency and accelerate tunneling speed, the company decided to develop the world's largest diameter hard rock tunneling machine, "Caucasus."

Reporter: With previous experience in developing shield machines, this development must have gone much smoother.

Jia Lianhui: We still faced many tricky problems. First, due to the large diameter of "Caucasus," ensuring the stability of the equipment and enhancing its geological adaptability was a significant challenge. Second, heavy snowfall in Georgia during winter led to narrow roads, making it difficult to transport large items. Therefore, we had to complete the shipping by early October 2020 to ensure the equipment reached the construction site on time. This made the design and manufacturing time for the team extremely tight. To ensure timely delivery, we adopted onsite delivery technology for the first time. This technology eliminated the need for equipment debugging and rectification in the factory, but it imposed higher requirements on design and manufacturing.

Reporter: Which technical issue was the most challenging?

Jia Lianhui: The most difficult "bone" to chew was how to ensure "Caucasus" operates stably under long distances, great depths, and strong rock hardness. We conducted targeted designs for the active hinge system, dual-speed reducer system, etc., achieving precise adjustments of the main machine's posture, enabling the equipment to maintain excellent tunneling capabilities under different geological conditions.

Reporter: What are your next R&D plans with your team?

Jia Lianhui: In the future, we will focus on basic technology research for tunnel boring equipment, develop new materials and processes to extend the service life of tunnel boring machines, and create more reliable, safer, and faster tunneling machines, promoting the manufacturing industry towards high-end, intelligent, and green development.

"Draw the blueprints on-site, write the code in the tunnel."

Reporter: Creating "national heavy equipment" requires a high-quality R&D team. How did you initially assemble this team?

Jia Lianhui: To enhance the company's innovation capabilities, about 20 years ago, I took the lead in forming the R&D team, guiding everyone to tackle key technological challenges. At the same time, I divided the team into four R&D groups focused on frontier technology, material research, electrical control, and mechanical power, clarifying each group's responsibilities and appointing technical backbones as group leaders.

Currently, the company’s R&D team has over 300 members, with 90% holding master's or doctoral degrees.

Reporter: With continuous technological development and product iteration, how do you ensure that your team members' technical levels remain at the forefront of the industry?

Jia Lianhui: In my view, solving problems is the best way to enhance the technical level of R&D personnel. I require team design personnel to be stationed on-site year-round, drawing blueprints on-site and writing code in the tunnel. By solving real-world problems, they continuously improve their technical abilities.

Reporter: What talent gaps do you see in the tunnel boring machine industry, and how can they be filled?

Jia Lianhui: In recent years, the tunnel boring machine industry has rapidly developed and is undergoing a critical transition from "manufacturing" to "intelligent manufacturing." To achieve this upgrade, we need a large number of comprehensive top talents in fields such as sensor detection and robotics. However, there is currently a significant shortage of such talent in the industry. To fill these gaps, we need to emphasize top-level design for "talent + industry," strengthen the talent chain around the industrial chain, and effectively promote the "four-chain connection" of talent chain, innovation chain, industry chain, and value chain. Relevant departments need to provide policy support to address the challenges of attracting, cultivating, retaining, and utilizing talent for enterprises.

Reporter: Young talent is the hope for the company's development. How do you cultivate young people and help them take on significant responsibilities quickly?

Jia Lianhui: We have established an end-to-end talent development system for the entire career cycle, outlining the career development path and learning map for employees from fresh graduates to technical experts. We have formulated the "Talent Strengthening Plan" and the "Three-Year Dream Building + Two-Year Enhancement" special plan for young talent cultivation, systematically planning the learning and growth path for young talents within their first five years of employment. At the same time, we leverage university resources to cultivate young talent. In response to the talent needs in the tunnel boring machine industry, we have collaborated with several universities to develop training programs.

Reporter: What message do you have for young people?

Jia Lianhui: Young friends, we are in an era full of challenges and hope. Please maintain the vitality and energy of youth, looking up at the stars while keeping your feet on the ground. In your work, endure loneliness and solitude, resist external temptations, and create your own wonderful life through dedicated effort.

[Reporter’s Note]

"We must create our own shield machine!" Jia Lianhui said. For him, making shield machines is not just work; it is a mission.

Jia Lianhui is not fighting alone. He joined the shield machine R&D project team as soon as he started his job.

"At that time, everyone was determined to break the monopoly of 'foreign shields.'" Jia Lianhui recalled that during that period, he adopted a "white + black" work mode, living a life between the dormitory and the technical center. Parameters such as pipe diameter, flow rate, and slurry ratio were repeatedly verified; dozens of simulation plans were created, and models were built in the laboratory for repeated testing...

During the development period, "running to construction sites" was a norm for Jia Lianhui. Especially during the trial excavation phase of the shield machine, he and his colleagues had to stay on-site for periods ranging from two months to six months.

Colleagues say that whenever Jia Lianhui travels to a new location, he always goes to the construction site with colleagues to understand the operation of each component in detail. He constantly reminds everyone that only by going deep into the front line and familiarizing themselves with the project can they design products that meet customer needs and construction conditions.

In Jia Lianhui's view, while shield machines are "big guys," their development requires meticulous work to ensure everything is flawless.

As the team leader, Jia Lianhui is not only well-versed in the overall design of various shield machines but also knows the parameters of components even better than the specific designers. In technical review meetings, he can always answer sharp questions from industry experts in detail, "earning everyone's respect."

"I want to lead the team to develop the best shield machine; this is the greatest motivation that has driven me forward all along," Jia Lianhui said. He hopes that he and his team will strive to "excavate" forward, making "Made in China" renowned worldwide.

- Joined

- Jun 27, 2024

- Messages

- 1,666

- Likes

- 10,825

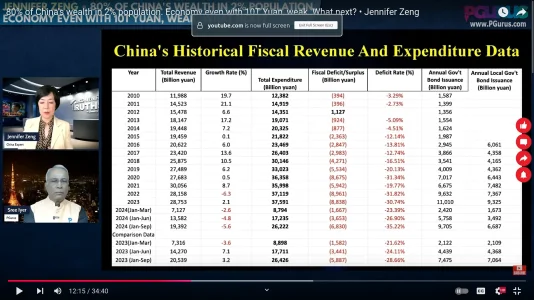

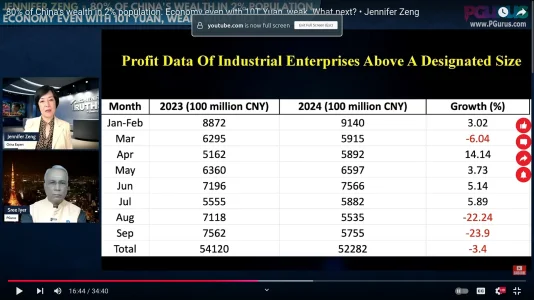

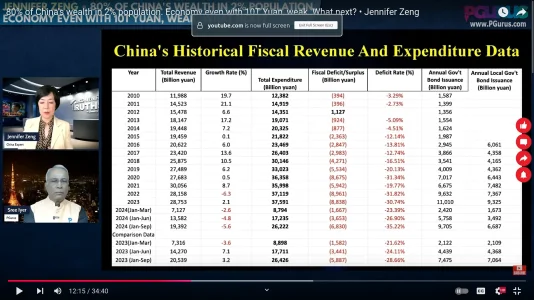

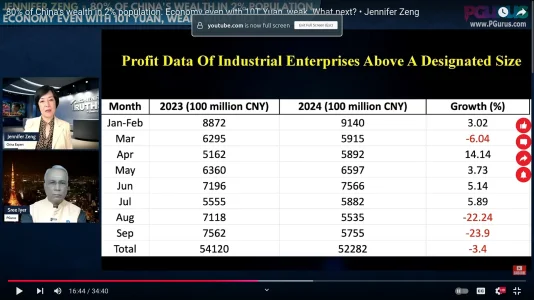

Some numbers discussed in this video. Not at all looking good for China's economy.

View: https://www.youtube.com/watch?v=TXicQH4fQEc

View: https://www.youtube.com/watch?v=TXicQH4fQEc

- Joined

- Jul 3, 2024

- Messages

- 1,573

- Likes

- 2,193

- The European Commission has passed tariffs aimed at Chinese EV makers after a year-long anti-subsidy probe, alleging high subsidies from the Chinese government.

- Automakers with a have been hit with tariffs as high as 35.3%, in addition to an existing 10% import duty, though the measures are lower for a number of automakers including Tesla vehicles from its Shanghai plant.

- A number of Chinese brands, including Leapmotor, have been working on setting up local production in Europe.

Europe Is Levying Tariffs Against Chinese EVs—See How High

Europe enacts its own tariffs against Chinese EVs after a year-long anti-subsidy probe, but the EV landscape is far more complicated compared to the US.

- Joined

- Jul 3, 2024

- Messages

- 747

- Likes

- 361

Afghanistan’s solar panel manufacturing factory.

China's intelligent production line

View: https://x.com/afghanaaam/status/1852411157019238894

China's intelligent production line

View: https://x.com/afghanaaam/status/1852411157019238894

- The European Commission has passed tariffs aimed at Chinese EV makers after a year-long anti-subsidy probe, alleging high subsidies from the Chinese government.

- Automakers with a have been hit with tariffs as high as 35.3%, in addition to an existing 10% import duty, though the measures are lower for a number of automakers including Tesla vehicles from its Shanghai plant.

- A number of Chinese brands, including Leapmotor, have been working on setting up local production in Europe.

Europe Is Levying Tariffs Against Chinese EVs—See How High

Europe enacts its own tariffs against Chinese EVs after a year-long anti-subsidy probe, but the EV landscape is far more complicated compared to the US.www.yahoo.com

View: https://www.youtube.com/watch?v=ur2Wr7eoW9Q

- Joined

- Jul 3, 2024

- Messages

- 1,573

- Likes

- 2,193

Despite the ongoing scrapping subsidy programme and significant price reductions, the Chinese market slowed for the second consecutive month. The September selling rate was 25.6 million units per year, an almost 4% decrease from August. The YTD selling rate averaged 24.4 million units per year, compared to last year's total LV sales of 25.2 million units. In YoY terms, sales fell by 6% in September and 2.8% YTD. New energy vehicles (NEVs), predominantly Chinese brands, continued to grow, accounting for 55% of PV sales in September, while sales of internal combustion engine (ICE) vehicles continued to decline sharply.

However, we continue to exercise caution regarding the sales outlook amidst signs of economic deceleration. The GDP growth rate dipped to 4.6% in Q3, falling beneath the government's annual target of 5% and down from the 4.7% YoY growth recorded in Q2. The downturn in the real estate sector and a lacklustre job market have contributed to a sustained decline in the LCV market over several months.

- Joined

- Jul 3, 2024

- Messages

- 1,573

- Likes

- 2,193

SAIC Motor, once China’s largest carmaker, has reported a shocking drop in profits, with net profit plummeting by 93.5%. The company’s latest financial report paints a grim picture

View: https://www.youtube.com/watch?v=J2jkvpxGP_M

Shanghai (Gasgoo)- In the first three quarters of 2024, SAIC Motor recorded a consolidated operating income of 430.482 billion yuan, reflecting a year-on-year decrease of 17.74%. During this period, its net profit attributable to shareholders stood at 6.907 billion yuan, marking a 39.45% drop from the same period last year.

In the third quarter (Q3) alone, SAIC Motor logged revenue of 145.796 billion yuan, down by 25.91% compared to the previous year, while net profit attributable to shareholders reached 279.69 million yuan.

SAIC Motor cited a combination of internal pressures and external risks impacting results, though the company remains committed to innovation-driven transformation to bolster resilience. In the first three quarters this year, the group achieved wholesale sales of 2.65 million vehicles and retail sales of 3.23 million vehicles, with improved delivery quality and supply chain stability setting a strong foundation for a fourth-quarter (Q4) sales push.

View: https://www.youtube.com/watch?v=J2jkvpxGP_M

Shanghai (Gasgoo)- In the first three quarters of 2024, SAIC Motor recorded a consolidated operating income of 430.482 billion yuan, reflecting a year-on-year decrease of 17.74%. During this period, its net profit attributable to shareholders stood at 6.907 billion yuan, marking a 39.45% drop from the same period last year.

In the third quarter (Q3) alone, SAIC Motor logged revenue of 145.796 billion yuan, down by 25.91% compared to the previous year, while net profit attributable to shareholders reached 279.69 million yuan.

SAIC Motor cited a combination of internal pressures and external risks impacting results, though the company remains committed to innovation-driven transformation to bolster resilience. In the first three quarters this year, the group achieved wholesale sales of 2.65 million vehicles and retail sales of 3.23 million vehicles, with improved delivery quality and supply chain stability setting a strong foundation for a fourth-quarter (Q4) sales push.

- Joined

- Jul 3, 2024

- Messages

- 1,573

- Likes

- 2,193

SAIC Motor (

Key Financial Results

- Revenue: CN¥145.8b (down 26% from 3Q 2023).

- Net income: CN¥279.7m (down 94% from 3Q 2023).

- Profit margin: 0.2% (down from 2.2% in 3Q 2023).

- EPS: CN¥0.024 (down from CN¥0.38 in 3Q 2023)

SAIC Motor Third Quarter 2024 Earnings: Misses Expectations

SAIC Motor ( SHSE:600104 ) Third Quarter 2024 Results Key Financial Results Revenue: CN¥145.8b (down 26% from 3Q 2023...

English conversation, an Indian engineer talked about experiences worked in Huawei.

View: https://youtu.be/ObAcJwdtTWg?si=V16LYohrAZ0AqEHY

View: https://youtu.be/ObAcJwdtTWg?si=V16LYohrAZ0AqEHY

Users who are viewing this thread

Total: 7 (members: 0, guests: 7)

Latest Replies

-

Jokes Thread

- Nishaanbaaz

-

Brown Coolie Musings

- asl001

-

Operation Sindoor and Aftermath

- Clawreed

-

Indian Special Forces

- hkdas

-

US: News & Discussions

- shade2

-