- Joined

- Jul 1, 2024

- Messages

- 354

- Likes

- 2,627

Right that's wat I want to sayIf It really has 53% indigenous content then it's better to change the mk2 Design and run it on al31 engine science murrican engines are gone now.

Extra virgin air force with 12 years of lch testing 15 years of lch testing and even then had to be forced to place ordersChad Indian Navy with 1-2 Year trial and Induction.

Vs

Virgin Indian Army with 10+year trial only for ATAGS.

So what components do we source from Russia still? Since you presented a detailed reply. Can you please list what kind of manufacturing technologies we have already mastered and what need to be mastered to make 1. AL-31F 2. F-414 Class Reliable Engine.After the press release on procurement of 240 AL-31FP at a cost of Rs 26k crores, there has been considerable confusion among defense aficionados regarding the indigenous content.

Well, allow me to clarify your doubts.

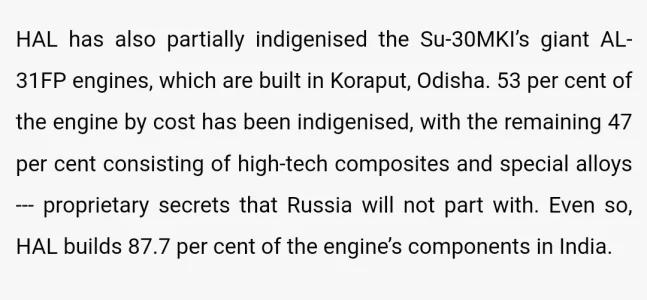

Like Su-30MKI licensed production in Nashik, manufacturing of AL-31FP in Koraput consists of 4 phases. In the first phase, engines were manufactured from SKD kits supplied by NPO Saturn, in the next phase there were some percentage of indigenisation but still we were assembling the entire entire from CKD kits. The fourth phase entails manufacturing from raw material stage.

In this phase, all castings,forgings,sheet metal job everything is done by HAL in house from raw materials either sourced from other PSUs/private industry and OEM in Russia.

View attachment 8389

So what is the present indigenisation level of AL-31FP? It's 53 percent. Seems low right. But here's a caveat. This 53 percent is in terms of cost of the engine. In reality, HAL makes 87.7 percent of the assemblies and sub assemblies at Koraput from raw material stage.

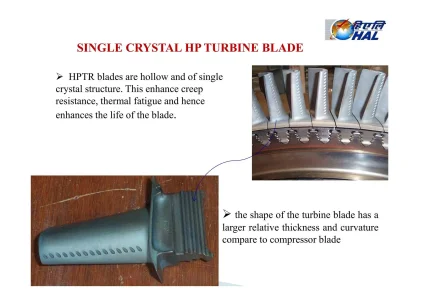

Everything you can think of in a gas turbine or jet engine is made here. IGV , LPC aerofoils, discs and stators , HPC bladed,discs and stators, annular combustor , intermediate casing , HPT blades and vanes, LPT blades and vanes, flame holder assembly, and con di axi symmetric nozzle petals,flaps . The tech transfer involved in AL-31FP is much higher than what is envisaged for the much routed GE F414 INS6 Make in India deal.

Retired HAL chief , Mr T Suvarna Raju has gone on record saying that all assemblies and sub assemblies , forgings and castings are made here. He handed over the 50th AL-31FP made from raw material stage to Air Marshal SB Deo.

View attachment 8390

This was in Oct 17.

So people will ask about the significance of 54 percent indigenous content in this present deal. Well, this figure is by cost. When this is implemented, the figure of 87 percent of total components made here by HAL will further increase.

DMRL has an active project to enhance the service life of the entire engine. AL-31FP has a technical life of 2000 hrs. DMRL has already perfected the design and mass manufacture of 3rd gen SC turbine blades. AL-31FP used first gen SC. This can be used along with indigenously developed TVC to increase the performance of AL-31FP but this will require certification from cemilac and an extensive flight test campaign.

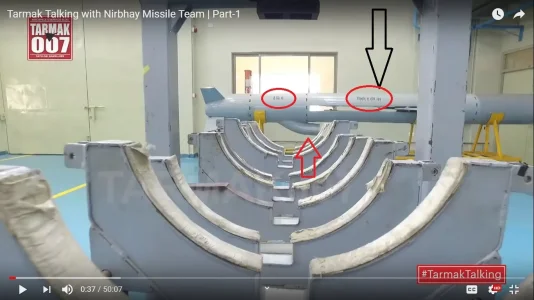

Guys I know this video is not about INdian defence system. Any idea which missile - the developer is talking about in this video:

View: https://youtu.be/VPSm9gJkPxU?t=508

should share this with drdo

should share this with drdoGuys I know this video is not about INdian defence system. Any idea which missile - the developer is talking about in this video:

View: https://youtu.be/VPSm9gJkPxU?t=508

So what components do we source from Russia still? Since you presented a detailed reply. Can you please list what kind of manufacturing technologies we have already mastered and what need to be mastered to make 1. AL-31F 2. F-414 Class Reliable Engine.

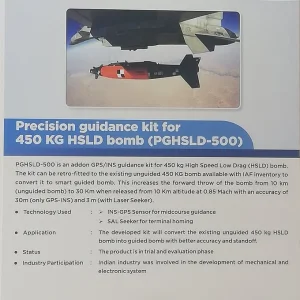

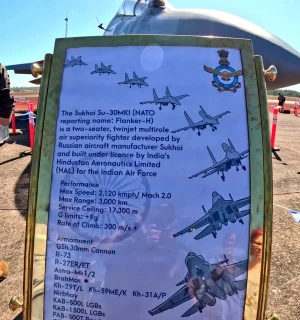

Great find sirjiThis specs sheet was displayed at Pitch Black 24. Initially I thought that mention of Nirbhay must be a fluke.

View attachment 8441

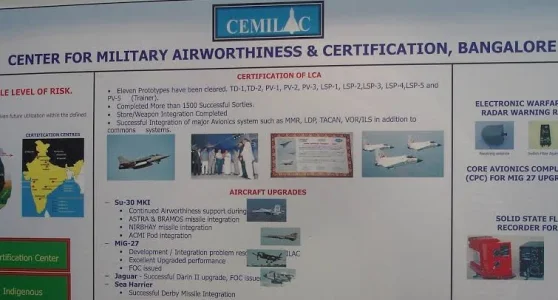

But then I came across this.

View attachment 8442

This slide is a bit old. The ground launched Nirbhay TD missile had already been integrated with Su-30MKI. Each Sukhoi can carry three Nirbhays.

Plus there's also a definitive ALCM variant of Nirbhay in the works. Most likely ready by now. There hasn't been any news on this for the past few years. I am certain, captive carriage trials have already taken place. Launching this from a Su-30MKI won't be a big deal. Maybe we will come to know when DRDO babus wish to reveal.

View attachment 8443

View attachment 8444

View attachment 8446

Even with low service life it can be beneficial as it will keep the manufacturing running.Some of the sub assemblies of annular combustor. The TBC coatings.

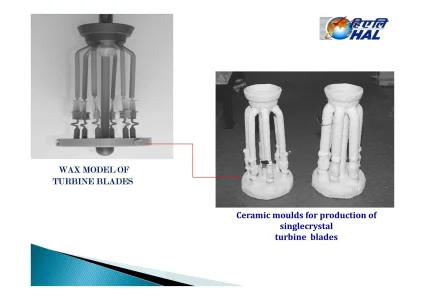

One of the most critical tech is casting of SC turbine blades using investment casting. I have written about this in detail in DFI.

AL-31FP is already a reliable engine. Only drawback is that it's TTSL is less. 2000 hrs. Vs 6000 hrs of GE F414.

We need to shift to AL-41F1S instead of AL-31FP. This will require minor mods to the air intake and engine nacelles. But nothing major. AL-41F1S has a 6000 hr service life. Max thrust of 142 kN.

VKS ie Russians have already decided to switch to AL-41F1S on their Su-30 SM2.

NPO Saturn has developed another AL-31FP which has the exact same dimensions as the older engine but incorporates tech from 41 to enhance service life to 6000 hrs. New HPT and LPT. New HPC. We can also go for that.

Any reason we aren't going in either for a new iteration of AL-31FP or the AL-41FS if as you've pointed out the modifications in the TF per se & presumably the mfg processes are minor & easily achievable without incurring much cost ?Some of the sub assemblies of annular combustor. The TBC coatings.

One of the most critical tech is casting of SC turbine blades using investment casting. I have written about this in detail in DFI.

AL-31FP is already a reliable engine. Only drawback is that it's TTSL is less. 2000 hrs. Vs 6000 hrs of GE F414.

We need to shift to AL-41F1S instead of AL-31FP. This will require minor mods to the air intake and engine nacelles. But nothing major. AL-41F1S has a 6000 hr service life. Max thrust of 142 kN.

VKS ie Russians have already decided to switch to AL-41F1S on their Su-30 SM2.

NPO Saturn has developed another AL-31FP which has the exact same dimensions as the older engine but incorporates tech from 41 to enhance service life to 6000 hrs. New HPT and LPT. New HPC. We can also go for that.

110kn engine test facilityWhat is AMCA engine LOL?

So what components do we source from Russia still? Since you presented a detailed reply. Can you please list what kind of manufacturing technologies we have already mastered and what need to be mastered to make 1. AL-31F 2. F-414 Class Reliable Engine.