- Joined

- Jul 2, 2024

- Messages

- 774

- Likes

- 3,646

Are these the Su-35 engines?... 122kN upgraded to 132kN?

There's even a 142kN version for Su-37.

They will ask for exorbitant amount of money for change, I want to know can we replace those systems from our own systems like in SC blades and reach close to 6000 hr service life?!Some of the sub assemblies of annular combustor. The TBC coatings.

One of the most critical tech is casting of SC turbine blades using investment casting. I have written about this in detail in DFI.

AL-31FP is already a reliable engine. Only drawback is that it's TTSL is less. 2000 hrs. Vs 6000 hrs of GE F414.

We need to shift to AL-41F1S instead of AL-31FP. This will require minor mods to the air intake and engine nacelles. But nothing major. AL-41F1S has a 6000 hr service life. Max thrust of 142 kN.

VKS ie Russians have already decided to switch to AL-41F1S on their Su-30 SM2.

NPO Saturn has developed another AL-31FP which has the exact same dimensions as the older engine but incorporates tech from 41 to enhance service life to 6000 hrs. New HPT and LPT. New HPC. We can also go for that.

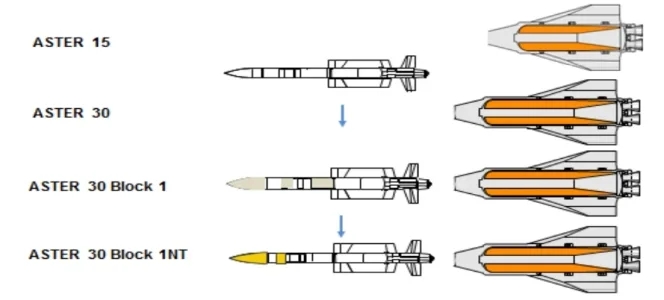

Or to be more precise; just a single, modular interceptor that can be tailored for different threats.

M1 missile is different from M2 and M3 missiles.Or to be more precise; just a single, modular interceptor that can be tailored for different threats.

> You've a missile with similar and hence proven planform of Akash-NG and Barak-8 as the baseline interceptor.

Who's knows maybe we "replace" both Akash-NG and Barak-8 in future with M1 in a bid to declutter things

> Add a medium-thrust but sustained burning booster to it and now you've a long range SAM for maneuvering targets.

> Replace the previous booster with a high-thrust but fast burning booster and now you've a short-ranged ABM.

Pretty ingenious way of having a multi-tier system where instead of making a distinct missile for each tier you just need the additional expense of a booster and a TVC assembly; nothing more than that.

If I'm not wrong then MBDA is the only firm to currently utilize this concept in their Aster series to its full potential.

View attachment 8593

Well to some extent the new Barak-MX series also does it but then again it has just two missile and lacks dedicated ABM capabilities.

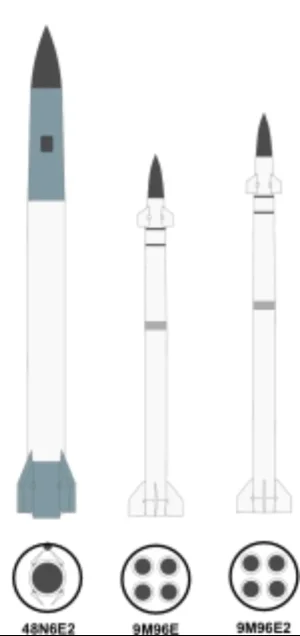

Other than that, every multi-tier SAM system uses different missiles.

From Russian/Chinese S-400...

View attachment 8594

...to USA's Standard Missile series.

View attachment 8595

I am having a doubt that how can M1 achieve 150km range when the dimensions look similar to Akash-NG and MRSAM. May be the range is ~100km.

M1 missile is different from M2 and M3 missiles.

M1 looks more like Akash-NG whereas M2 and M3 look like MRSAM with different boosters.

Akash ng indian while mrsam is indo israeliAnyone please, what's the need for having Akash-G & MRSAM both with similar ranges?

Akash ng indian while mrsam is indo israeli

Wasn't there a recent poster showing Akash NG's range as ~30 km??!!Anyone please, what's the need for having Akash-G & MRSAM both with similar ranges?

We can't keep manufacturing LRSAM for very long as it's not viable. When you've a smaller home market and also a very unreliable one then the only way to survive is on foreign markets. Today people are all praise for MKU and Tonbo Imaging but imagine what would have happened if they had not received international orders in their initial years.Yes, but beyond that?... now shouldn't we settle for one of the two, whichever suits better?

Presently I know of no capability or op.role difference between the two.

Don't give ideas, God forbid if they like itThey should name it Ball Buster (or how 'bout Nut Cracker??).

@NutcrackerThey should name it Ball Buster or Egg Scrambler (or how 'bout Nut Cracker??).