- Joined

- Jul 2, 2024

- Messages

- 1,414

- Likes

- 9,107

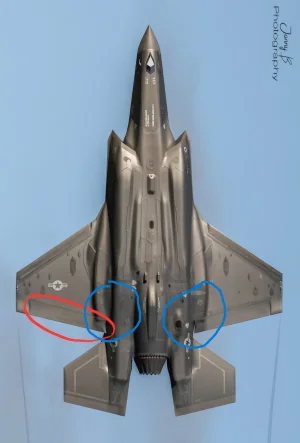

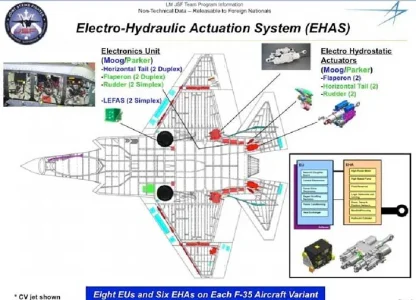

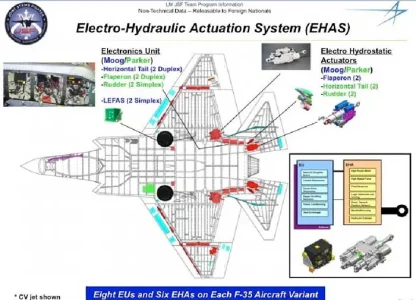

No one uses "pure" hydraulic actuators in planes anymore; whenever the term hydraulic is used it's colloquially for Electro-Hydraulic Actuators or EHA.

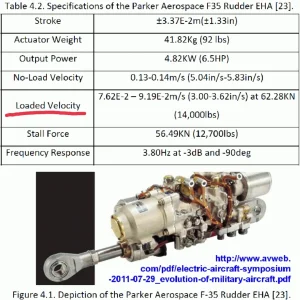

Similar to the F-35 EHA I posted earlier is the one on the rudder. Even with 7,000kg of load that actuators manages a velocity of more than 3" per second.

With available tech a similar EMA would be both heavier (the EHA's just 40kg) and a lot slower.

If we go the pure EMA route to get similar power and speed output like an EHA, then the size of the motor and gearbox would become bigger.

On the contrary only EHAs can move big control surfaces very fastIDK if hydraulic actuators can move very fast a big control surface.

Similar to the F-35 EHA I posted earlier is the one on the rudder. Even with 7,000kg of load that actuators manages a velocity of more than 3" per second.

With available tech a similar EMA would be both heavier (the EHA's just 40kg) and a lot slower.

Again, we don't use "pure" hydraulics that has all the lines and reservoirs and pumps. We yes ultra compact EHAs that's pretty much self contained in itself with just a cable coming out of the unit.It is logical to reduce space by eliminating hydraullic reservoirs, pumps, pipes, motors by just an EM motor.

If we go the pure EMA route to get similar power and speed output like an EHA, then the size of the motor and gearbox would become bigger.

& you being his doctor

& you being his doctor

Let's not waste time over timeline when we all got the point.

Let's not waste time over timeline when we all got the point.